Flint & Walling Commander Pro 300 User Manual

Page 5

5

95 North Oak Street • Kendallville, IN 46755

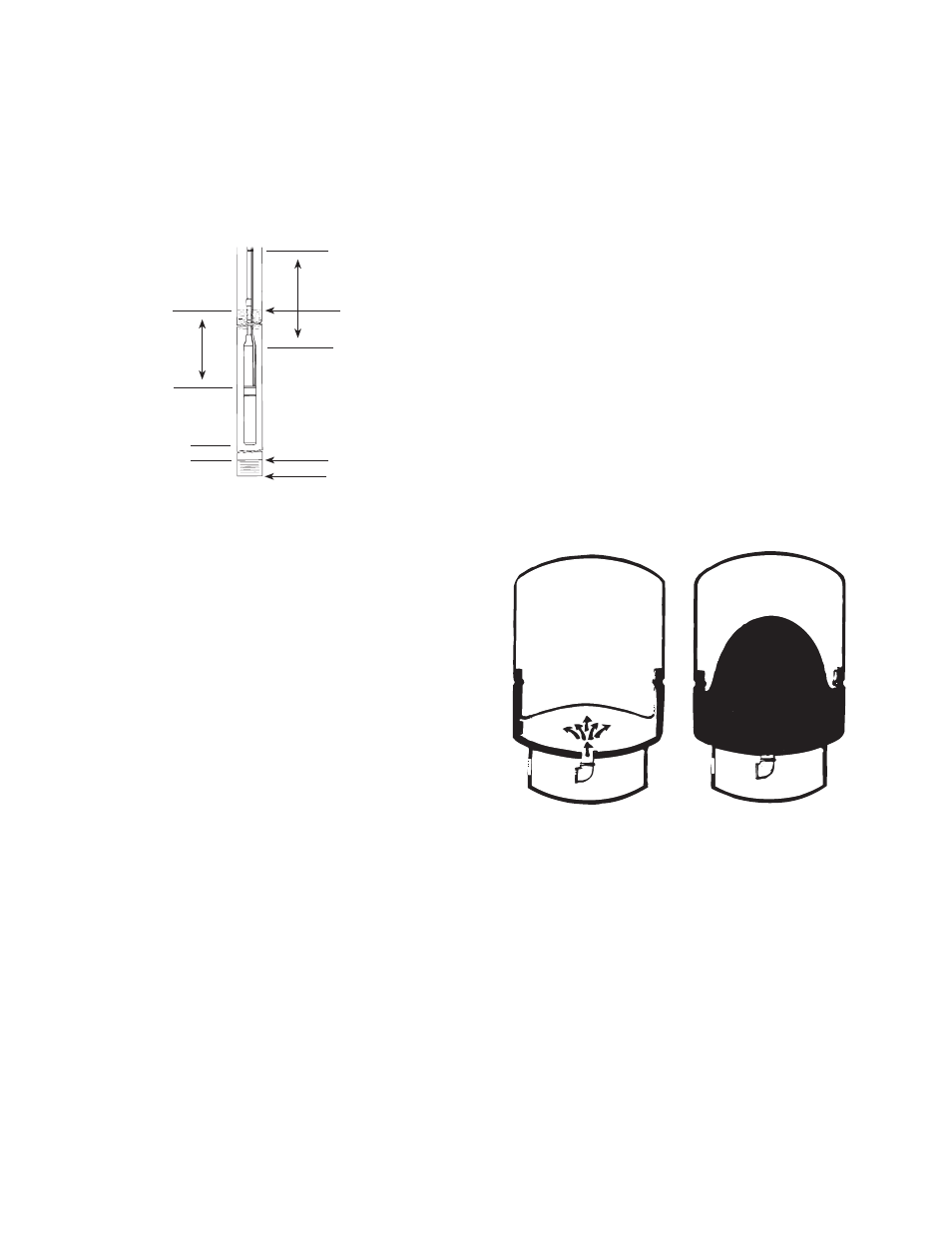

8. The complete pump and motor should be

submerged at least ten feet below the draw

down level of the well, and the motor should be

a minimum of ten feet off the bottom of the well

(Figure 4).

9. The Piping — Install the pump with pipe of the

same diameter as the discharge port of the pump

or larger.

IL0077

Figure 4

10 ft.

10 ft.

10 ft. Min.

Drawn Down Water

Level

Top of Well Screen

Bottom of Well

NOTE: Use of pipe smaller that the discharge port

of the pump will restrict the capacity of the pump and

lower its operating performance.

10. Check Valve — A check valve is required on all

submersible installations. This valve maintains

water within the pipe when the pump is running. A

line check should be installed within 25 feet of the

pump and below the draw down level of the water

supply.

a. For well depths exceeding 200 feet, it is

suggested that an additional check valve be

installed every 125 feet.

b. An additional check valve should be installed in

the horizontal line between the well top and the

pressure tank (See Figures 1 & 2).

CAUTION: Make certain that the check valve is

pointing in the right direction, arrow pointing towards

the tank.

11. Torque Arrester — To center the pump as it is

being lowered into the well, a torque arrester is

recommended. This will also minimize the pump

whipping due to the starting torque of the motor

(See Figure 2).

NOTE: On plastic pipe installations a torque

arrester must be installed. Cable guards should also

be installed.

12. Pressure Tank — The purpose of the pressure

tank is to allow an amount of water to be drawn

before the pressure drops enough to cause the

pump to start. Without a pressure tank, the pump

would start and stop continuously when water is

drawn. There are two types of pressure tanks,

the standard tank that requires an air volume

control and the pre-charged tank.

a. On a standard pneumatic tank system, air

is introduced to compensate for that which

is absorbed by the water. Each time the

pump cycles air is added to the tank through

a bleeder and snifter valve. The excess air

is released by a float assembly (air volume

control) in the upper side tapping of the tank

(See Figure 2).

b. In a pre-charged tank, a flexible diaphragm

or bladder separates the air and water areas

of the tank. The air chamber is pre-charged

by means of a tire valve with pressure 2 PSI

less than the cut-on pressure of the pump.

Because the air is not in contact with the

water, it cannot be absorbed by the water.

Therefore, the original charge of air is never

lost.

13. In pre-charged tank systems, none of the

fittings for air introduction or air level control are

required (Figure 1). The piping in the well is also

different for the two systems. The pre-charged

tank system does not require a bleeder orifice

assembly, which simplifies the installation.

IL0096

Figure 5

Pump On. Water Enters

The Reservoir

System Filled.

Pump Off

14. The tank size should be selected to keep

the pump starts per day as low as practical

for maximum life. Excessive motor cycling

accelerates motor bearing and spline wear, pump

wear and contact erosion. Use as a guide, 100

starts per day (24 hours) on single phase motors

and 300 starts per day on three phase units.

15. Pressure Switch — The pressure switch provides

for automatic operation. The pump starts when

the pressure drops to the switch cut-in setting

and stops when the pressure reaches the switch

cut-out setting. The pressure switch must be

installed as close to the tank as possible (Figures

1 & 2).

16. Pressure Relief Valve — A properly sized

pressure relief valve must be installed on any