Flint & Walling Commander Pro 300 User Manual

Page 4

4

95 North Oak Street • Kendallville, IN 46755

ASSEMBLY

CAUTION: Be sure pump size corresponds with

horsepower size of motor. If pump size exceeds

recommended motor, overloading of motor and

damage to the motor could result.

1. If not yet assembled, check that the pump and

motor mounting faces are free from dirt.

2. Assemble the pump liquid end and motor

together so that mounting faces are in contact.

Then tighten assembly bolts evenly.

NOTE: Apply non-toxic FDA approved waterproof

grease such as Mobile 102, Texaco CYGNUS2661 or

equivalent to the coupling before assembly of pump

coupling to motor shaft. This will prolong spline life

and prevent abrasives from entering the spline area.

3. Check for free rotation of the pump and motor. A

slight drag is permissible.

4. Assemble the pump lead guard over the motor

leads.

CAUTION: Do not cut or pinch lead wire during

assembly.

5. Assemble suction screen to pump mounting ring.

IL0094

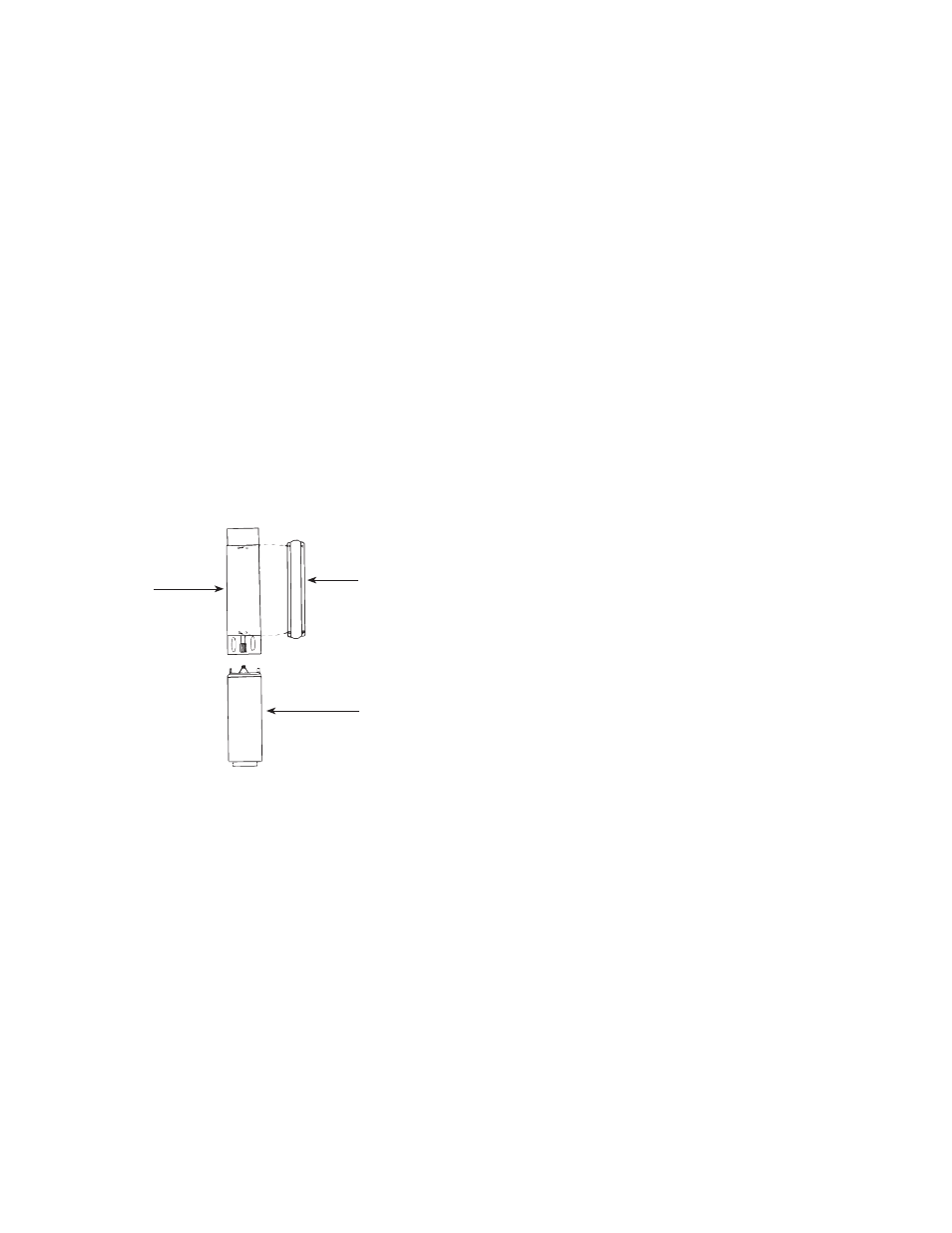

Figure 3

Liquid End

Lead Wire

Guard

Motor

PRE-INSTALLATION

To save possible added expense and extra trips,

observe and complete as many as possible of the

following precautions and pre-installation procedures

before going to the job site or beginning the

installation.

IMPORTANT PRECAUTIONS

1. Prior to installation, inspect the pump for damage.

Check for free pump and motor rotation. A slight

drag is permissible.

2. Check to make certain that the voltage of the

motor end and control agree with the available

phase and voltage. Check power source. Check

electrical supply for correct fusing, correct wire

size, and adequate grounding and transformer

size.

WARNING: Since most submersible pump problems

are electrical, it is very important that all electrical

work be done properly. Therefore, all electrical hook-

up work or electrical service work should be done by a

qualified electrician or service man only!

3. Throughout installation, take care not to damage

the insulation of the electrical cable or motor

leads. Never support the weight of the unit by

electrical cable or motor leads.

4. Before the pump is installed, the well should be

pumped free of sand and other foreign matter

with a test pump.

The warranty is void if it is

used to clean the well.

5. Follow wiring directions in the control box and

make momentary tests to see that motor runs.

(It is normal to hear some noise from the pump

when you are momentarily testing it).

Do not run

pump dry for more than three (3) seconds.

MAJOR WELL COMPONENTS (see Figures 1 & 2)

1. Submersible Pump — A submersible pump is a

multi-stage centrifugal. Each stage consists of an

impeller and diffuser. Water pressure increases in

equal amounts as it passes from stage to stage.

The more stages, the higher the pressure the

pump will develop.

2. Submersible Motor — Submersible pumps can

be powered by either single phase or three phase

motors. Make certain that the motor corresponds

with the horsepower required by the pump.

Failure to do so, could result in overloading of the

motor and motor damage.

3. Control Box — Single phase submersible motors

require the use of an above ground control box

for starting. Operation of these motors without

control boxes or with incorrect boxes can result in

failure of motors which will void the warranty.

4. Magnetic Starters and Overload Protection

— Three phase submersible motors require the

use of an above ground magnetic starter and

overload protection. Operation of these motors

without or incorrect starters and protectors will

result in the failure of motor which will void

the warranty. See Magnetic Starter Chart for

the correct selection of magnetic starters and

ambient compensated quick trip protectors.

5. The Well — The well should be sand free and

have a sufficient flow of water to supply the

pump. Clear well of sand and any other foreign

matter with a test pump before installing the new

submersible pump.

CAUTION: Using the submersible pump to clean the

well will void the warranty.

6. When drilling a new well in an area where sand is

a problem, a sand screen should be installed to

protect the pump and motor.

7. The well should be straight so damage during

installation does not occur to the pump or motor

by becoming lodged in a crooked well casing.

READ THESE INSTRUCTIONS COMPLETELY BEFORE INSTALLATION