Flint & Walling Commander Pro 300 User Manual

Page 7

7

95 North Oak Street • Kendallville, IN 46755

2. The ground wire to be used must be of the same

size as the submersible power cable. It may be

insulated or bare. If insulated, it must be green,

with or without yellow stripe(s). The ground wire

may be part of, or separate from, the supply

cable. It may be continuous or spliced above the

pump along with the supply cable.

3. The motor lead wire assembly includes a green

insulated ground lead. Splice the ground wire to

the green insulated lead as shown in Figure 6.

4. The other end of the ground wire will be

connected to the power supply grounding

terminal or to the control panel ground bar if it is

connected to the power supply ground.

NOTE: See section entitled Grounding for detailed

grounding instructions.

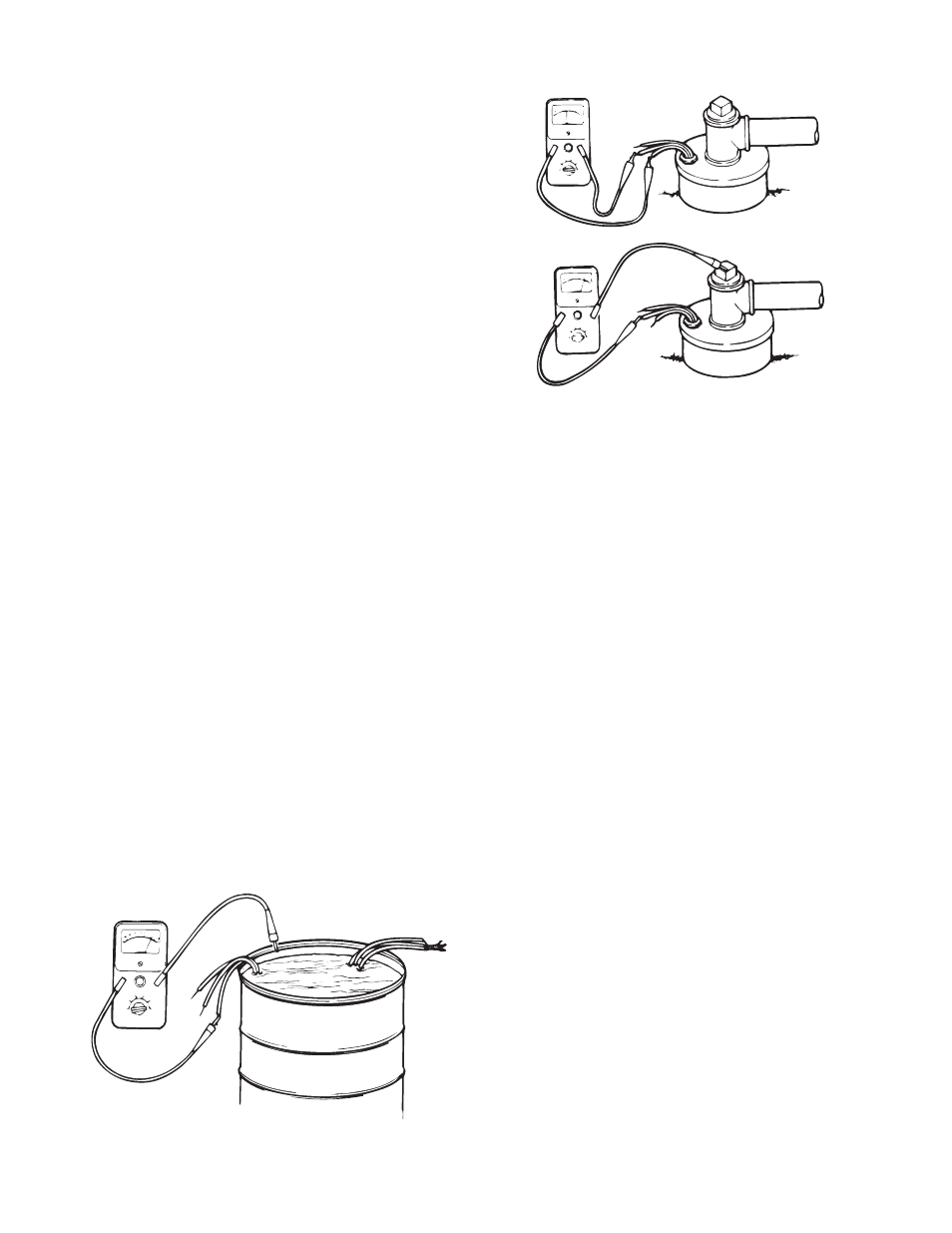

INSULATION AND CONTINUITY TEST

1. It is recommended that this test be done when

the splicing is complete and pump is being test

run in a tank of water. This test can be repeated

after installation in well but before the final

electrical hook-up is made to the control box or

pressure switch (see Figures 7 & 8).

2. Zero the ohmmeter by clipping the leads together

and adjusting the zero ohm knob until the needle

indicates zero. Zero the ohmmeter before each

use or every time selector switch is changed.

3. Clip one ohmmeter lead to bare cable end.

4. Clip the other lead to edge of steel tank in which

pump and cable are submerged. If pump is

already in the well, clip lead to discharge pipe

metal well casing or bare ground wire.

5. A reading of less that 1,000,000 ohms indicates

that cable or splice is grounded. Slowly raise

cable from the water at the ohmmeter end.

When trouble spot moves clear of the water,

needle will move toward infinity reading. In

an old installation with the pump in the well,

a reading of 20,000 ohms or less indicates a

breakdown in the insulation; in this case pull the

pump.

PUMP INSTALLATION

IL0098

Figure 7

IL0099

Figure 8

1. The following pump installation instructions use

Schedule 80 PVC pipe or galvanized pipe. If

either of these two types are used, a foot clamp

or vise will be required to hold the PVC or

galvanized pipe when connecting the next pipe

length.

2. Install the pump in a well which is sand-free,

straight, and has sufficient flow of water to supply

the pump. Clear well of sand and any other

foreign matter with a test pump before installing

the submersible pump.

NOTE: Using the submersible pump to clean the

well will void the warranty. When drilling a new well

in an area where sand is a problem, a sand screen

must be installed to protect the pump and motor.

3. Chlorinate the well first. Drop 24 to 48 HTH

(chlorine) tablets into the well before lowering

the pump into the well. This will prevent

contamination and the growth of iron bacteria

which could later plug the well and the pump.

The chlorinated water will be pumped out of the

system when testing the pump flow.

4. BE SURE the top edge of the well casing is

perfectly smooth; sharp or jagged edges can cut

or scrape the cable and cause a short.

5. Install a line check valve within 25 feet of the

pump and below the draw down level of the water

supply. The check valve should be the same size

as the discharge outlet of the pump or larger.

NOTE: Use of pipe smaller that the discharge

tapping of the pump will restrict the capacity of the

pump and lower its operating performance.

6. When connecting the first length of pipe and

placing the pump in the well casing, care should

be maintained to center the pump in the well. It

is easier to handle the pump if a short piece of