Reassembly – Flint & Walling Centrifugal Packages - CJ103 User Manual

Page 8

8

95 North Oak Street • Kendallville, IN 46755 • Copyright © 2010. All rights reserved.

MAINTENANCE

Lubrication

The pumps and motors require no lubrication.

The ball bearings of the motor have been greased

at the factory. Under normal operating conditions

they should require no further greasing.

Winterizing your Pump

Cracked pump housings caused by freezing are

not covered by warranty. To protect your pump

from freezing, for best results remove the pump

and store in a warm environment. If pump cannot

be removed from your system, remove both

drain plugs, one on the suction flange and one

at the bottom rear of the pump (see fig 2 in the

instructions.) Allow the water to completely drain

from the pump. Re-install both drain plugs and fill

pump with RV type antifreeze. Antifreeze also acts

as a rust inhibitor. It will help keep rust build up to

a minimum and seals lubricated inside the pump

while it is not in use.

ROTARY SEAL ASSEMBLY REPLACEMENT

Disassembly

When disassembling the pump, care

should be taken not to damage the gaskets. If torn or

damaged, replace with new gasket (see parts list).

1. Remove the four (4) pump through bolts that

connect the mounting ring to the pump body.

Remove the pump body, taking care not to

damage the gasket or o-ring.

2. Remove the impellers. CJ103 Models are

single stage units, having one impeller. Using

a 9/16” open end wrench, hold the motor shaft

flat and unthread the impeller by turning it

counterclockwise. The motor shaft flat area is

located in the middle of the mounting ring.

3. CJ101 models are multi stage units, having

two or more impellers and one or more

intermediate stages. Using an 11/16” open

end wrench on the motor shaft extension

flat, remove the first impeller by turning or

counterclockwise. Remove the intermediate

stage (stages) taking care not to damage the

gasket (gaskets) and unthread the remaining

impellers.

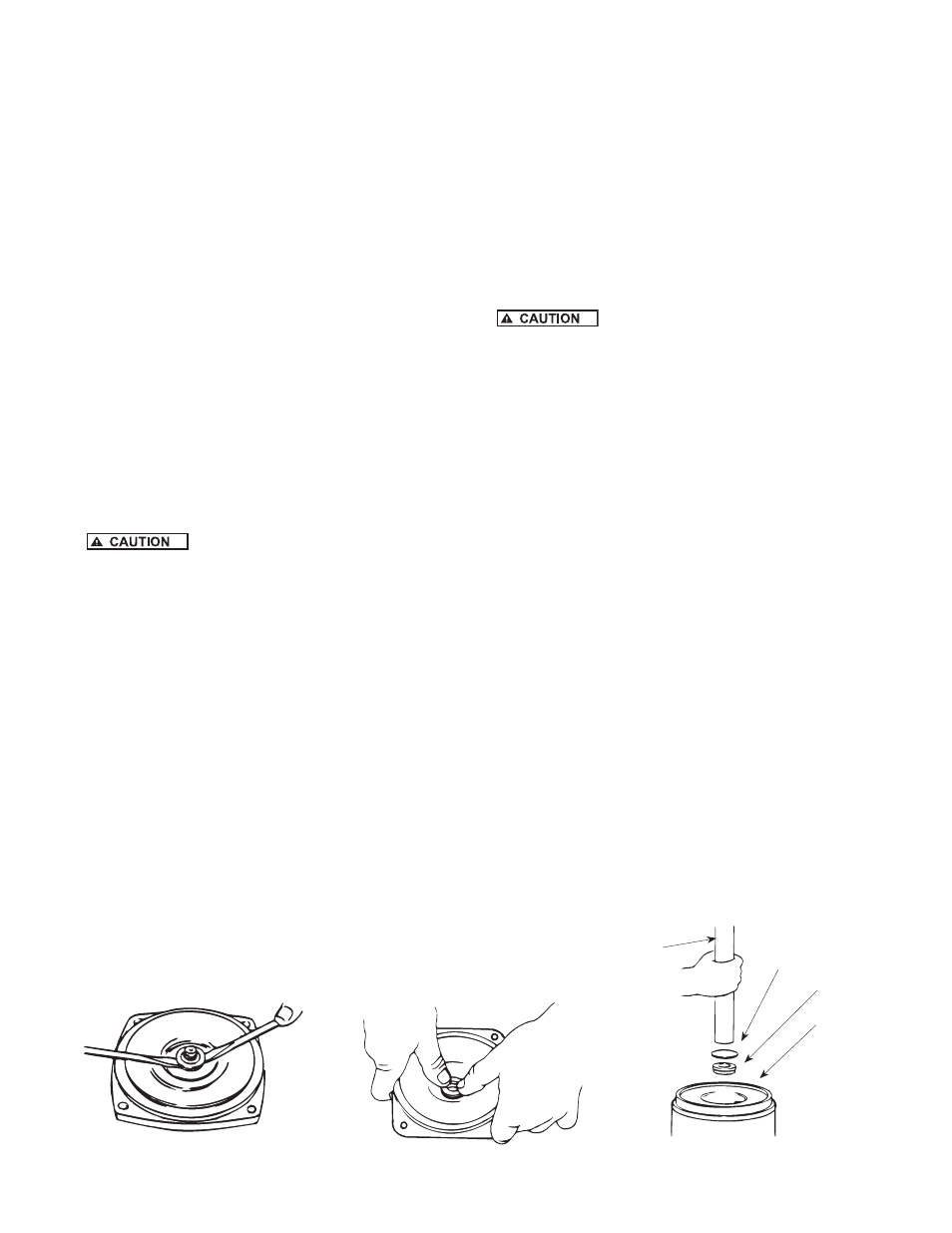

4. Remove the mechanical seal assembly. The

rotary portion of the seal assembly (carbon

ring, Buna-N gasket and spring) will easily slide

off the end of the shaft. The ceramic portion

can be pried out of the rubber seating using

two (2) screwdrivers (see Figure 13).

Reassembly

The precision lapped faces of the

mechanical seal are easily damaged. Handle the

replacement seal carefully. Short seal life will result if

seal faces (ceramic & carbon) are nicked, scratched or

dirty.

1. Clean the seal cavity of the mounting ring and

the motor shaft thoroughly.

2. Apply liquid soap (one drop only) to the outside

of the Buna-N gasket that houses the ceramic

seal seat. With thumb pressure, press the

ceramic seat, polished face up, squarely into

the seal cavity (see Figure 14).

3. If seal does not seat squarely, remove and

reclean the seal cavity. Place a cardboard

washer over the polished seal face and carefully

press into place using a piece of pipe or tubing

(see Figure 15). Discard cardboard washer.

4. Apply liquid soap (one drop only) to the inside

diameter of the rubber drive ring. Slip rubber

drive ring (carbon face down) and the spring

over the shaft.

5. Reassemble the pump by following the reverse

order of the disassembly instructions.

MOTOR REPLACEMENT

1. Nema J motors can be replaced in the field

with any standard Nema J jet pump motor by

referring to the following instructions and the

attached parts list.

Figure 13 - Remove Mechanical Seal

Figure 14 - Press in Seal

Figure 15 - If Necessary, Press with

Cardboard and Pipe

IL0173

IL0168

IL0169

3/4” Pipe

- Press

Carefully

NOTE:

Cardboard Washer

Protects Seal Face

Seal

Seal

Cavity