Pump performance chart d – Flint & Walling Centrifugal Packages - CJ103 User Manual

Page 4

4

95 North Oak Street • Kendallville, IN 46755 • Copyright © 2010. All rights reserved.

INSPECTION AND STORAGE

When unpacking the unit, inspect carefully for any

damage that may have occurred during shipment.

If the unit is received sometime before it can be

used, it should be inspected, recrated and stored

in a dry location.

LOCATION

IMPORTANT: In installations where property

damage might result from an inoperative or

leaking pump due to power outages, discharge

line blockage or any other reason, a back-up

system (s) and/or warning system (s) should be

used.Install a gate valve and union in the suction

and discharge lines. For removal of the pump for

service, close the gate valve and disconnect the

union.

1. Locate pump as close to the fluid source as

possible.

2. Place unit where the motor electrical

components and piping are protected from the

weather and extremes of heat, humidity and

below freezing temperatures.

3. Mount unit in a dry location that is easily

accessible for inspection and maintenance. If

a dry location is not available, mount it on a

foundation well above the wet floor.

4. Allow ample clearance around unit for free air

circulation.

5. CJ103 Series pumps incorporate a discharge

port on the pump casing that can be adjusted

in 90 increments. If necessary, adjust the

discharge port to accommodate the specific

application. Pump performance will not be

affected by the position of the discharge port.

SUCTION LIMITATIONS

1. Units are non self-priming. Normally after

being primed the total suction lift of the pump

is 25 feet. Suction lift varies depending upon

elevation (altitude) and water temperature. See

Practical Suction Lift chart.

2. Where liquids at or near their boiling points

are being handled, the supply must be located

above the suction, so that the available NPSH

will be greater than that required by the unit.

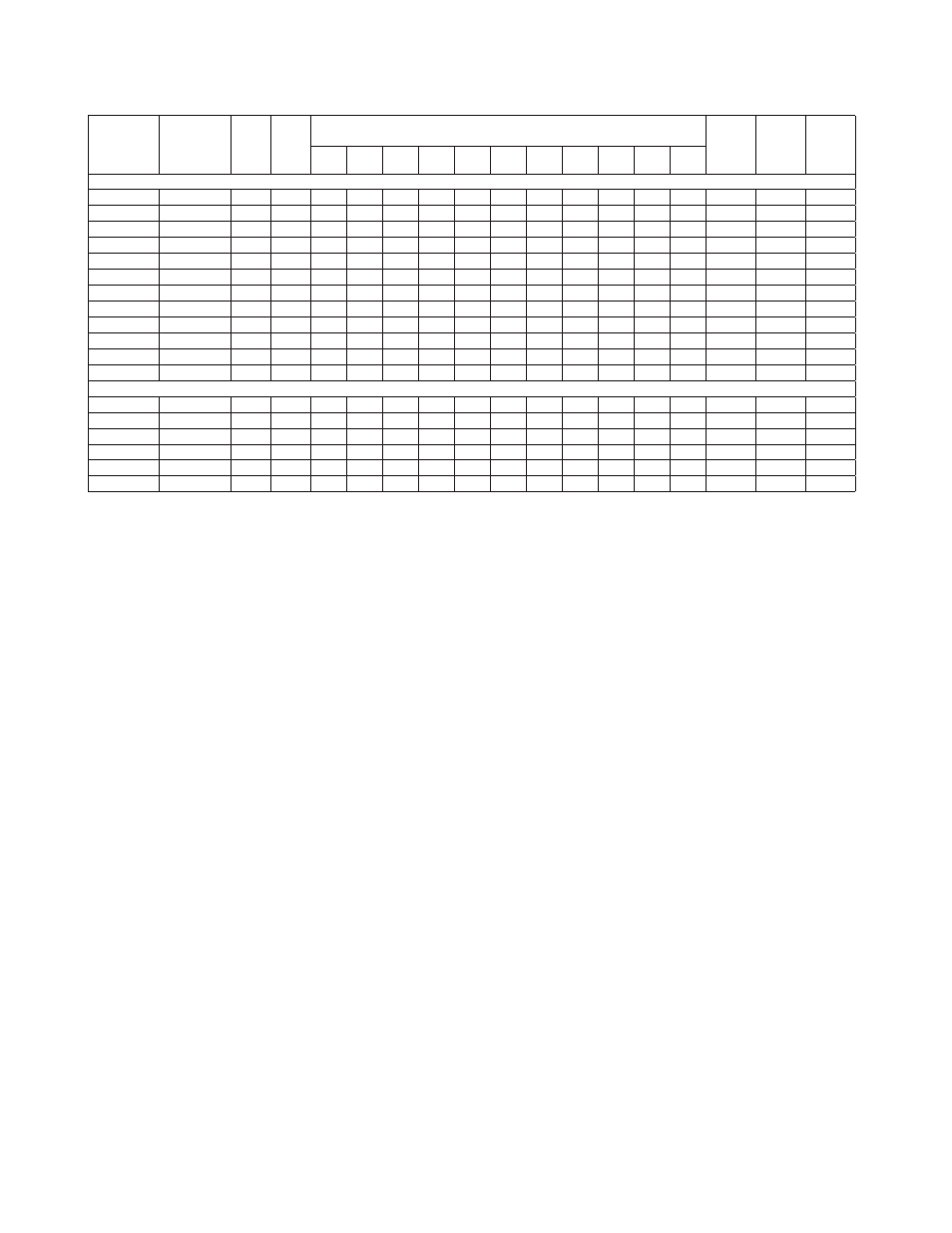

Pump Performance

Chart D

To convert to feet of head, multiply by 2.31.

* Operation of pump in this range may result in m otor damage.

Do not exceed the maximum case pressure and maximum liquid temperature rating of the pump.

Suction & Discharge Tapping: 1-1/2” X 1-1/4”

Motor Voltage:

Single phase:

1/3 - 115V; 1/2 thru 2 HP - 115/230V; 3 HP - 230V, 60HZ

Three phase:

1/2 thru 2 HP - 208-230/460V - 50/60HZ

3 HP - 208-230/460V - 60HZ

Single

Phase

Model No.

Three

Phase

Model No.

HP

Stage

GPM at Total Pressure in PSI

Max.

Press.

PSI

Max.

Case

Press.

PSI

Max.

Liquid

Temp.

15

20

25

30

35

40

50

60

70

80

90

BRASS IMPELLER MODELS

CJ103031

-

1/3

1

41

30

10

27

100

200°F

CJ103051

CJ103053

1/2

1

48

40

27

30

100

200°F

CJ103071

CJ103073

3/4

1

62

58

46

31

33

100

200°F

CJ103101

CJ103103

1

1

70

66

58

48

34

40

100

200°F

CJ103151

CJ103153

1-1/2

1

*

75

70

61

51

36

44

100

200°F

CJ103201

CJ103203

2

1

*

*

79

77

68

57

45

100

200°F

CJ101B071 CJ101B073

3/4

2

*

*

32

29

25

22

5

53

160

200°F

CJ101B101 CJ101B103

1

2

*

*

35

32

29

27

23

3

62

160

200°F

CJ101B151 CJ101B153 1-1/2

2

*

*

42

39

37

34

28

19

68

160

200°F

CJ101B201 CJ101B203

2

2

*

*

45

44

43

40

34

26

70

160

200°F

CJ101C201 CJ101C203

2

3

*

*

42

41

40

38

35

31

27

20

7

93

160

200°F

CJ101C301 CJ101C303

3

3

*

*

51

50

49

43

41

40

35

29

21

95

160

200°F

THERMOPLASTIC IMPELLER MODELS

CJ101P071 CJ101P073

3/4

2

*

*

31

28

23

20

48

160

160°F

CJ101P101 CJ101P103

1

2

*

*

34

31

30

29

19

60

160

160°F

CJ101P151 CJ101P153 1-1/2

2

*

*

46

44

41

37

31

14

61

160

160°F

CJ101P201 CJ101P203

2

2

*

*

45

44

42

39

31

21

65

160

160°F

CJ101D201 CJ101D153

2

3

*

*

41

40

38

37

33

29

24

17

89

160

160°F

CJ101D301 CJ101D303

3

3

*

*

*

46

45

45

42

38

33

27

18

93

160

160°F