Chart e, Il0102 – Flint & Walling Centrifugal Packages - CJ103 User Manual

Page 7

7

95 North Oak Street • Kendallville, IN 46755 • Copyright © 2010. All rights reserved.

line, pump casing, and discharge line up to the

level of supply.

3. Where the pump is operating with suction

lift and the suction line is equipped with a

foot valve, remove the priming plug from the

discharge tee (see Figures 5-8) and fill the

pump body and suction pipe completely with

water. No additional water will be needed for

subsequent start-ups unless the pump body is

drained.

4. After the pump is turned on it will require 2-5

minutes before all air is evacuated from the

suction line and water begins to flow. If there

is no water after 5 minutes, turn the pump off

and check the following:

5. Any air leaks on the suction line must be

eliminated.

6. Suction pipe inlet should be a minimum of 5

feet below the water level.

7. Total suction lift cannot be greater than 25 feet.

8. Any restrictions in the discharge pipe, such as a

closed valve must be eliminated.

NOTE: Unit must be full of liquid before operating.

Never run dry, or against a closed discharge. Dry

running or running unit against a closed discharge

will cause damage to the shaft seal. Do not pump

dirty water or abrasive liquids, otherwise the same

may occur as if running dry.

MOTOR ROTATION

1. Single phase models are one (1) rotation only

(counterclockwise when facing the pump

suction tapping) and cannot be reversed.

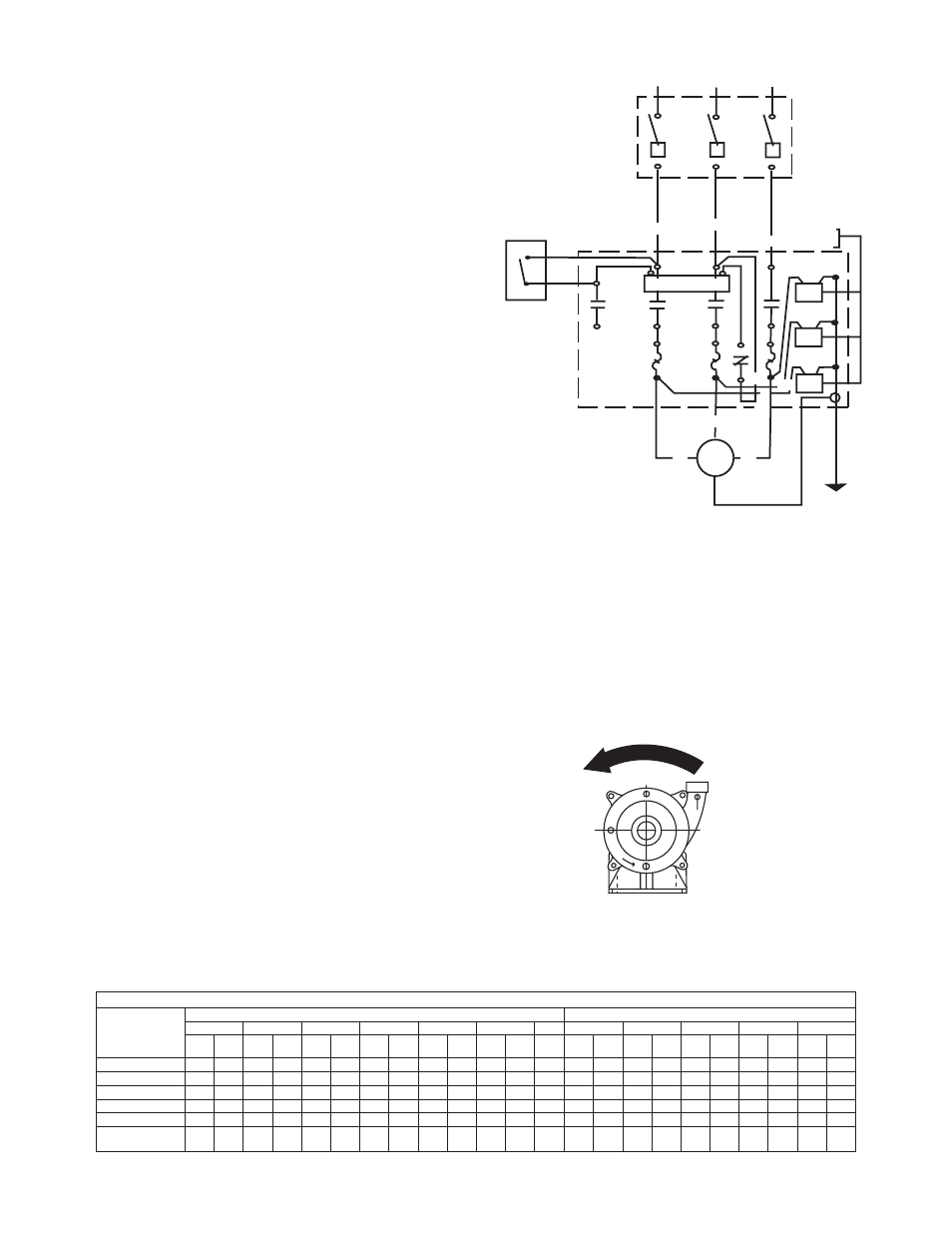

Figure 11 - Magnetic Starter Wiring Diagram Three Phase

IL0102

Pressure

Switch

Fused

Disconnect

Switch

Lightning

Arrestor

Motor

#10 or Heavier Copper Ground Wire, Connect

to 10 Ft. Ground Rod or Well Casing

T1

T3

T2

T1

T2

X2

T3

02

03

L2

M

V

W

L3

L1

2. Proper rotation of pump impeller is critical for

three phase pumps. Pump motor should turn

counterclockwise (CCW) when facing pump

suction tapping. Momentarily “bump” (apply

power for less than a second) the motor to check

for proper rotation. To change rotation on three

phase units, interchange any two (2) incoming

line (power) leads.

IL0416

Figure 12 - Correct Motor Rotation

Chart E

MINIMUM COPPER WIRE SIZE CHART (GAUGE)

DISTANCE FROM

MOTOR TO FUSE

BOX METER,

OR ELECTRICAL

OUTLET

SINGLE PHASE MOTORS

THREE PHASE MOTORS

1/3 HP

1/2 HP

3/4 HP

1 HP

1-1/2 HP

2 HP

3 HP

3/4 HP

1 HP

1-1/2 HP

2 HP

3 HP

115V 230V 115V 230V 115V 230V 115V 230V 115V 230V 115V 230V 230V 230V 460V 230V 460V 230V 460V 230V 460V 230V 460V

0-50’

14

14

12

14

12

14

10

14

10

12

10

12

10

14

14

14

14

14

14

14

14

14

14

50-100’

14

14

12

14

12

14

10

14

8

12

8

12

10

14

14

14

14

14

14

14

14

14

14

100-150’

14

14

12

14

10

14

10

12

6

12

6

12

10

14

14

14

14

14

14

14

14

14

14

150-200’

12

14

12

14

10

12

8

12

*

10

*

10

10

14

14

14

14

12

14

12

14

12

14

200-300’

12

14

10

14

8

12

6

10

*

10

*

10

8

14

14

12

14

12

14

10

12

10

12

Breaker Size

(Amps)

15

15

20

15

20

15

30

15

30

20

30

20

30

15

15

15

15

15

15

15

15

15

15

(*) Not economical to run in 115 volt, use 230 volts