Electrical – Flint & Walling Centrifugal Packages - CJ103 User Manual

Page 6

6

95 North Oak Street • Kendallville, IN 46755 • Copyright © 2010. All rights reserved.

ELECTRICAL

Hazardous voltage.

Can shock, burn

or cause death.

Failure to follow

warnings can

cause fatal or

severe shock

hazard or

equipment failure.

Ground motor before connecting

to electrical power supply.

Connect the motor frame to

equipment grounding conductor by

using green screw. Do not connect

green ground wire to any of the motor

leads.

Do not ground to a gas supply

line.

Turn off power to motor before working on electrical

connections.

Supply voltage must be within ±10% of nameplate

voltage. If in doubt consult a licensed electrician.

Use wire size specified in wiring Chart E. If possible,

connect pump to a separate branch circuit with no other

appliances on it. If wiring diagram on motor model plate

differs from diagram shown in figures 8, 9 & 10, follow

diagram on motor.

All wiring should be performed by a qualified electrician

and in accordance with the national and local electric

codes.

WIRING

1. Motor voltages will vary depending upon the

motor horsepower and phase. Refer to the

motor nameplate and the Motor Data Chart

(Chart C) for voltage and electrical data.

Make certain that the power supply

conforms to the electrical specifications of the motor

supplied. Failure to do so may cause premature motor

failure and will void the warranty.

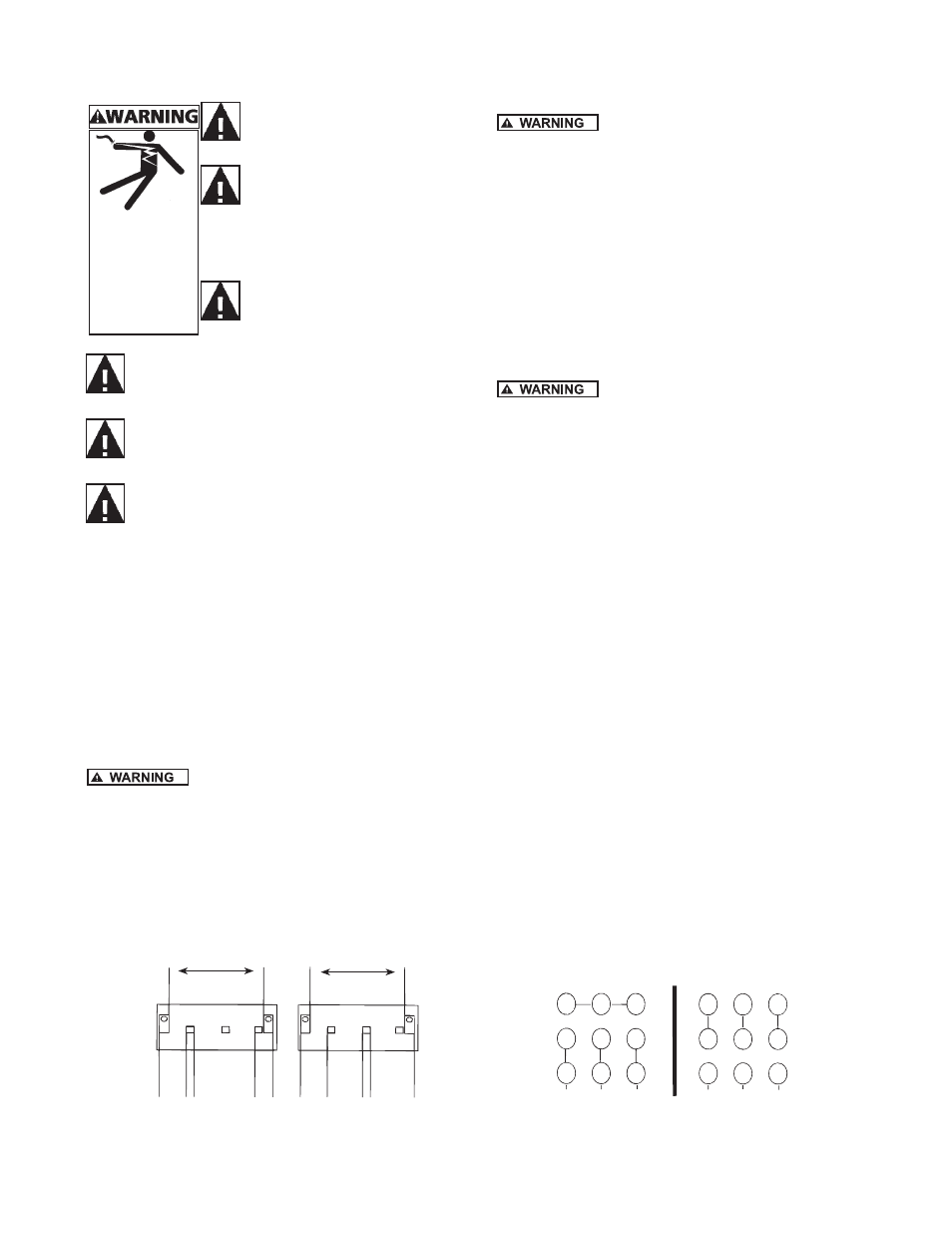

2. To change voltage, remove the rear access

cover, which is held in place with two (2)

screws. For proper electrical connection, refer

to the connection diagram located on the motor

nameplate or figures 8, 9 & 10.

Replace rear access cover before

starting or operating pump. Failure to do so can result

in personal injury.

MOTOR PROTECTION

1. All single phase motors have built in thermal

protection for all voltages. The overload

protects the motor against burnout from

overload of low voltage, high voltage and other

causes. The device is automatic and resets

itself once the temperature has dropped to

a safe point. Frequent tripping of the device

indicates trouble in the motor or power lines

and immediate attention is needed.

Never examine, make wiring changes

or touch the motor before disconnecting the main

electrical supply switch. The thermal device may have

opened the electrical circuit.

2. Three phase motors do not have a built in

thermal protection. It is recommended that a

properly sized magnetic or manual starter (both

with properly sized heaters) be used with all

three phase motors. Install starters following

instructions of the starter manufacturer. See

Figure 11 for magnetic starter wiring diagram.

3. All motors (single and three phase) should be

equipped with a correctly fused disconnect

switch to provide protection. consult local

or national electric codes for proper fuse

protection based on motor data chart (see

Charts C & E).

PRIMING

1. Before starting any centrifugal pump, it is

absolutely necessary that both the casing and

suction pipe be completely filled with liquid.

This priming can be accomplished by any of

the following methods:

2. When the liquid supply level is above the center

line of the pump, it is primed by opening the

suction and discharge valves. The inflowing

liquid will displace the air and fill the suction

IL0182

4

4

5

5

6

6

7

7

8

8

9

9

1

1

2

2

3

3

L

1

L

2

L

3

L

1

L

2

L

3

Figure 10 - Wiring Diagram for Three Phase

Low Voltage

230V

High Voltage

460V

IL0180

Figure 9 - Wiring Diagram for Single Phase

1/3-2 HP

L1

A

B

L2

L1

A

B

L2

115 VOLTS

SINGLE PHASE

230 VOLTS

SINGLE PHASE

LINE

LINE

Y

E

L

L

O

W

W

H

I

T

E

G

R

A

Y

R

E

D

T

A

N

Y

E

L

L

O

W

W

H

I

T

E

G

R

A

Y

R

E

D

T

A

N