Flint & Walling Centrifugal Packages - CJ103 User Manual

Page 5

5

95 North Oak Street • Kendallville, IN 46755 • Copyright © 2010. All rights reserved.

Practical Suction Lifts at Various Elevations and

Water Temperatures in Degrees Fahrenheit

Altitude

60º

80º

100º 120º 140º 160º 180º 200º

Sea Level -22

-21

-20

-18

-15

-10

-4

+5

2000

-20

-19

-18

-16

-12

-7

-1

+8

4000

-17

-16

-15

-13

-10

-4

+2

+12

6000

-15

-14

-13

-11

-7

-2

+6

+16

8000

-13

-12

-10

-8

-4

+2

+9

—

10000

-10

-9

-8

-6

-2

+4

+13

—

This table gives the maximum permissible suction lift or

the minimum head permitted on the suction side of a pump

at various altitudes and liquid temperatures. A minus sign

before a number indicates suction lift. A plus sign before a

number indicates minimum head. These figures are to be

used as a guide.

PIPING

1. Use galvanized piping, rigid plastic or other

suitable pipe that will not collapse under

suction or rupture due to pressure.

2. The diameter of the suction and discharge pipe

should be no smaller than the corresponding

tappings of the pump (see Figure 3 & 4). If long

runs are encountered larger pipe should be

used. Smaller pipe will reduce the capacity of

the pump.

3. All joints and connections should have Teflon

tape or pipe sealing compound (male threads

only) applied and drawn up tightly.

The entire system must be air and

water tight for efficient operation.

PUMP INSTALLATION

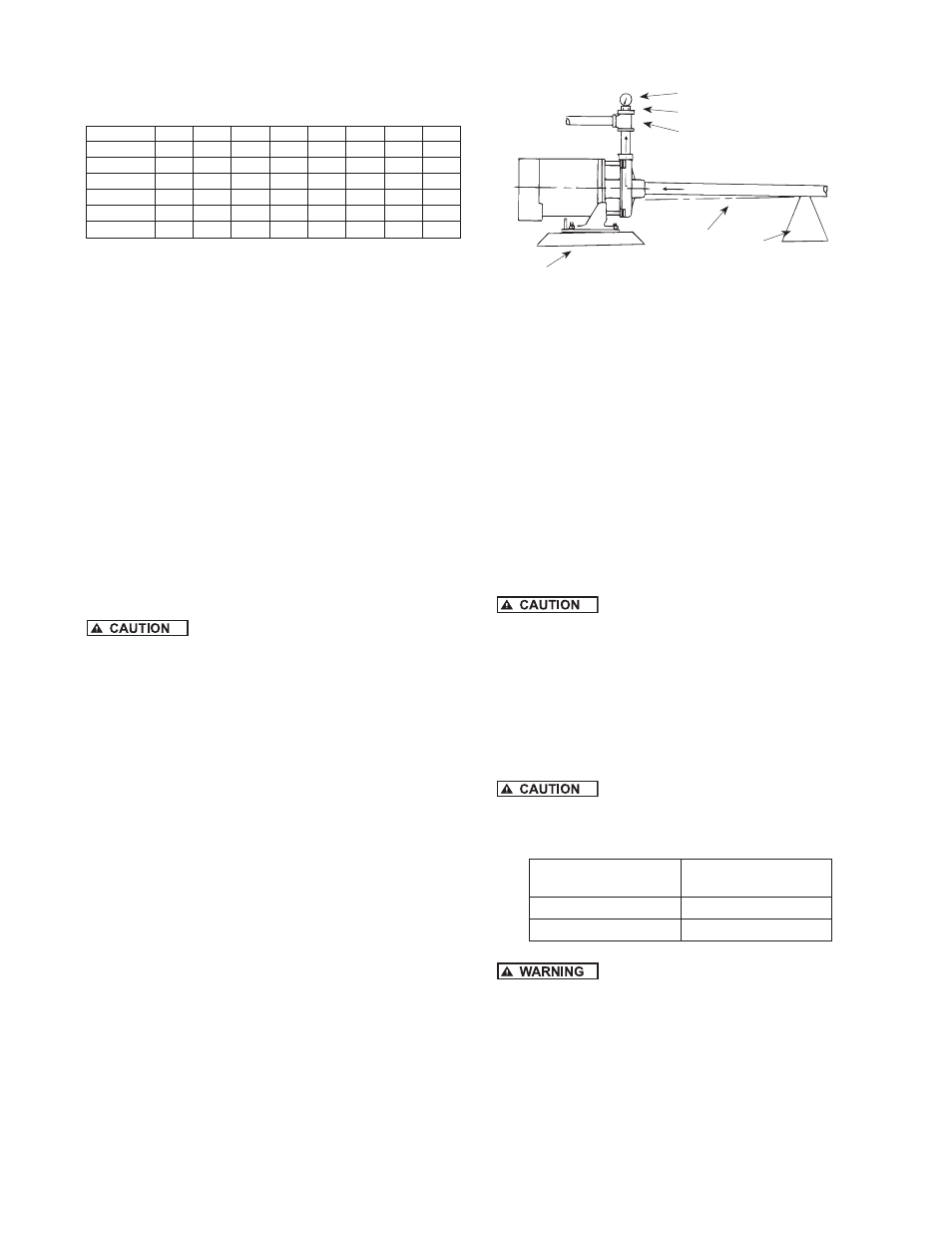

Refer to Figures 5, 6, and 7 for typical installations.

Both the suction and discharge pipe should be

supported at a point near the pump to avoid

strains being placed on the pump.

1. If the pump is used as part of a permanent

installation, secure to a rigid foundation with

appropriate fasteners.

2. Locate the pump as close to the water as

possible, keeping the suction pipe as short as

conditions permit.

3. Avoid dips or pockets in offset piping or air

will accumulate at high points which will make

priming difficult.

4. The suction pipe should slope upward to the

pump inlet. A horizontal suction line must have

a gradual rise to the pump.

IL0415

Pressure Gauge

Rigid

Foundation

Priming Plug

Level

Pipe

Support

Discharge Tee

Suction Pipe Installed with

Gradual Rise to Pump Inlet

Figure 7

5. On suction lift installations, a foot valve located

in the water or a check valve located as close

to the water as possible will reduce priming

time of the pump and help maintain prime. A

strainer must be used on the suction line to

filter out dirt and debris.

6. A priming tee installed in the pump discharge

port allows water to be poured into the pump

case and suction piping, which is required for

priming on suction lift installations.

7. Install a gate valve and union in the suction and

discharge lines. For removal of the pump for

service, close the gate valve and disconnect the

union.

Do not use a globe valve or other

restricting type of valve at the discharge. This will

seriously restrict the capacity of the pump.

8. Pressure Gauges - Properly sized vacuum or

pressure gauges can be installed in both the

suction and discharge pipe. The gauges will

enable observation of the pump’s performance

as well as detecting cavitation, vapor binding or

other unstable operation.

Use only components that are rated

higher than shut-off pressure of the system. Do not

exceed the pump’s maximum case pressure as listed in

the following table.

Models

Maximum Case

Pressure

CJ103

100 PSI

CJ101

160 PSI

A pressure relief valve of adequate

capacity must be installed on any installation where

the pump pressure can exceed the pressure tank’s

maximum working pressure or on systems where

the discharge line can be shut-off or obstructed.

Not providing a relief valve can cause extreme over

pressure which could result in personal injury and/or

property damage.