7 disassembly and repair, 8 accessories, 9 troubleshooting – Festo DSNU-…-KP User Manual

Page 8: 10 technical data

7

Disassembly and repair

Caution

Danger of injury due to uncontrolled movement of components!

Before dismantling:

• Make sure that the cylinder

8 and the clamping cartridge2 are exhausted.

• Loosen all of the mounting components on the cylinder

8 or clamping unit5.

• Recommendation: Send the product to our repair service.

This way the fine tuning and tests that are required will be taken into particular

consideration.

8

Accessories

Note

• Please select the corresponding accessories from our catalogue

(

www.festo.de\catalogue).

9

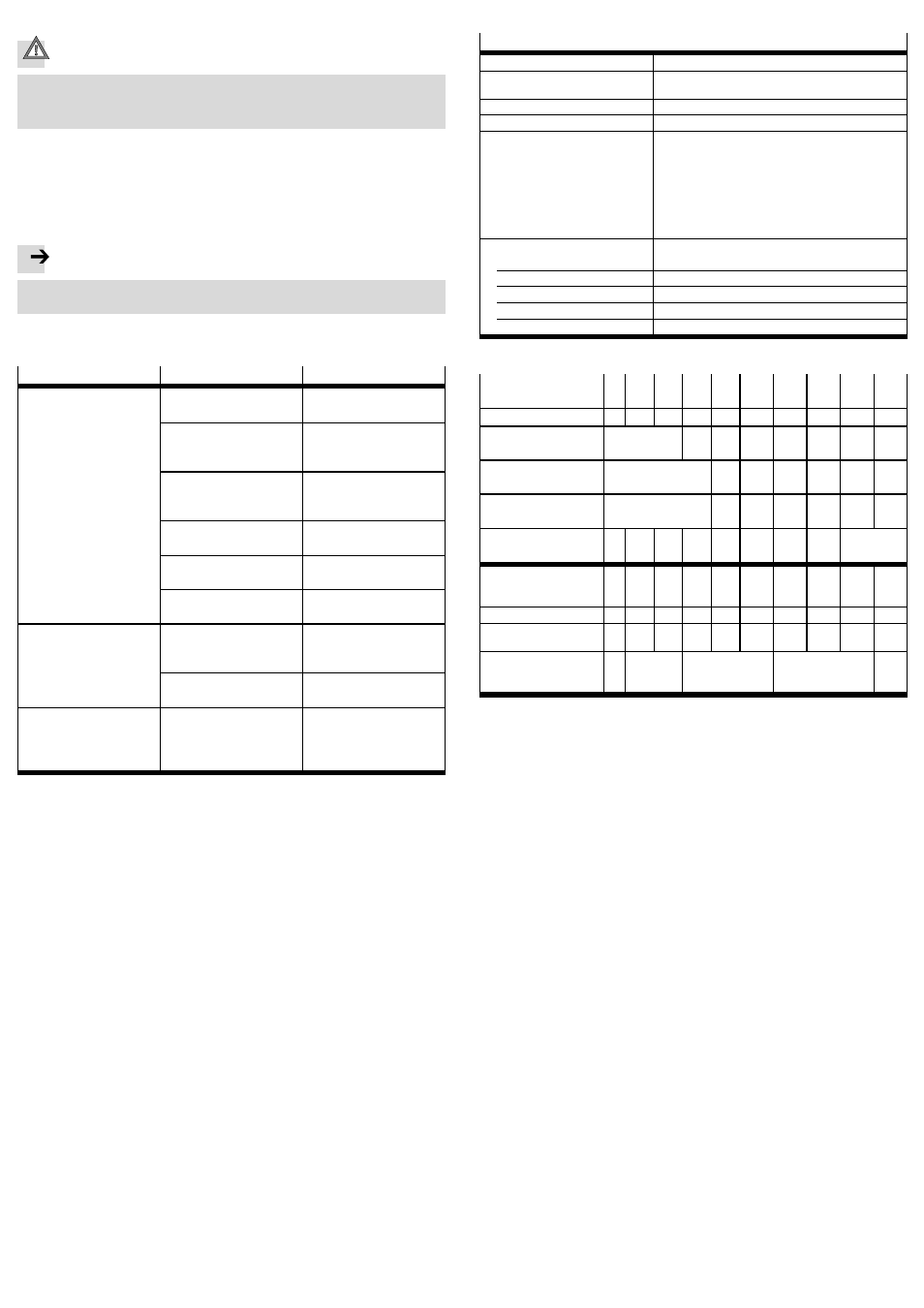

Troubleshooting

Malfunction

Possible cause

Remedy

The clamping rod

4

moves more than the

max. permitted axial play

despite an exhausted

clamping cartridge

2

Incorrect pneumatic ac-

tuation

Check pneumatic actu-

ation

Permanent manual un-

locking

Remove the mounting

screw

9 from the supply

port

1

Load too great and/or

static holding force ex-

ceeded

Reduce holding force, do

not exceed static holding

force

Contamination on the

clamping rod

4

(

Maintenance and

care)

Clamping cartridge

2 de-

fective

Replace clamping cart-

ridge

2

Wear

Send clamping cart-

ridge

2 to Festo

Clamping rod

4 does not

move despite an ex-

hausted clamping cart-

ridge

2

Insufficient operating

pressure on the clamping

cartridge

2

Increase operating pres-

sure (

Technical data)

Clamping cartridge

2 de-

fective

Send clamping cart-

ridge

2 to Festo

After pressurisation the

clamping rod

4 moves to

the end position at high

speed

Cylinder strikes against a

non-pressurised cham-

ber

Always strike against a

pressurised chamber

(

Commissioning)

Fig. 17

10

Technical data

KP

Mounting position

Any

Operating pressure

(on the clamping cartridge

2)

[bar]

3 … 10

Operating medium

Compressed air to ISO 8573-1:2010 [7:4:4]

Ambient temperature

[°C]

–10 … +80

Rod quality (KP/KPE)

– Steel, rod rolled smooth

(e.g. X20Cr13, X6CrNiMoTi 17222);

tensile strength > 650 N/mm

2

;

hardness [HB30] > 175

– Hardened steel: min. HRC 60

– Hard-chromium plated steel: thickness of layer min.

20 µm

– Tolerance range of rod diameter h8

– Surface roughness R

max.

= 4 µm

Material (clamping cartridge

2)

Housing:

Anodised aluminium

Piston:

Polyacetal

Spring:

Spring steel

Clamping jaws:

Brass

Seals:

Nitrile rubber, polyurethane

Fig. 18

KP-…

4-

80

6-

180

8-

350

10-

350

12-

600

16-

1000

20-

1400

20-

2000

25-

5000

32-

7500

KPE-…

4

6

8

10

12

16

–

20

25

32

ADN-…-KP

–

20/

25

32

40

50

63

80/

100

–

DNC-…-KP

–

32

40

50

63

80/

100

125

DSBC-…-C

–

32

40

50

63

80/

100

125

DSNU-…-KP

8/

10

12/

16

20

25

32

40

50

63

–

Clamping rod

∅

Dia-

meter

[mm]

4

6

8

10

12

16

20

20

25

32

Supply port

1

M5 M5

M5

M5

M5

G

Á

G

Á

G

Á

G

Á

G

Á

Static holding

force

[N]

80

180

350

350

600

1000

1400

2000

5000

7500

Axial play under

load

Dia-

meter

[mm]

0.2 0.3

0.5

0.8

1.8

Fig. 19