2 pneumatic installation, Connecting the tubing of the cylinder 8, 4 commissioning – Festo DSNU-…-KP User Manual

Page 7: 5 operation, 1 clamping during operation, 2 moving out of a clamped parking position, 6 maintenance and care

3.2 Pneumatic installation

Connecting the tubing for the clamping cartridge

2/clamping unit5:

1. Remove the mounting screw

9 on

the supply port

1 of the clamping

cartridge

2.

2. Insert a push-in fitting

(M5 DIN 912 or G

Á) into the sup-

ply port

1 of the clamping cart-

ridge

2.

The tightening torque is 0.5 Nm.

Fig. 12

1

2

5

9

Connecting the tubing of the cylinder

8:

• Connect the tubing of the clamping cartridge

2 and the cylinder8 with the direc-

tional control valves intended for this purpose.

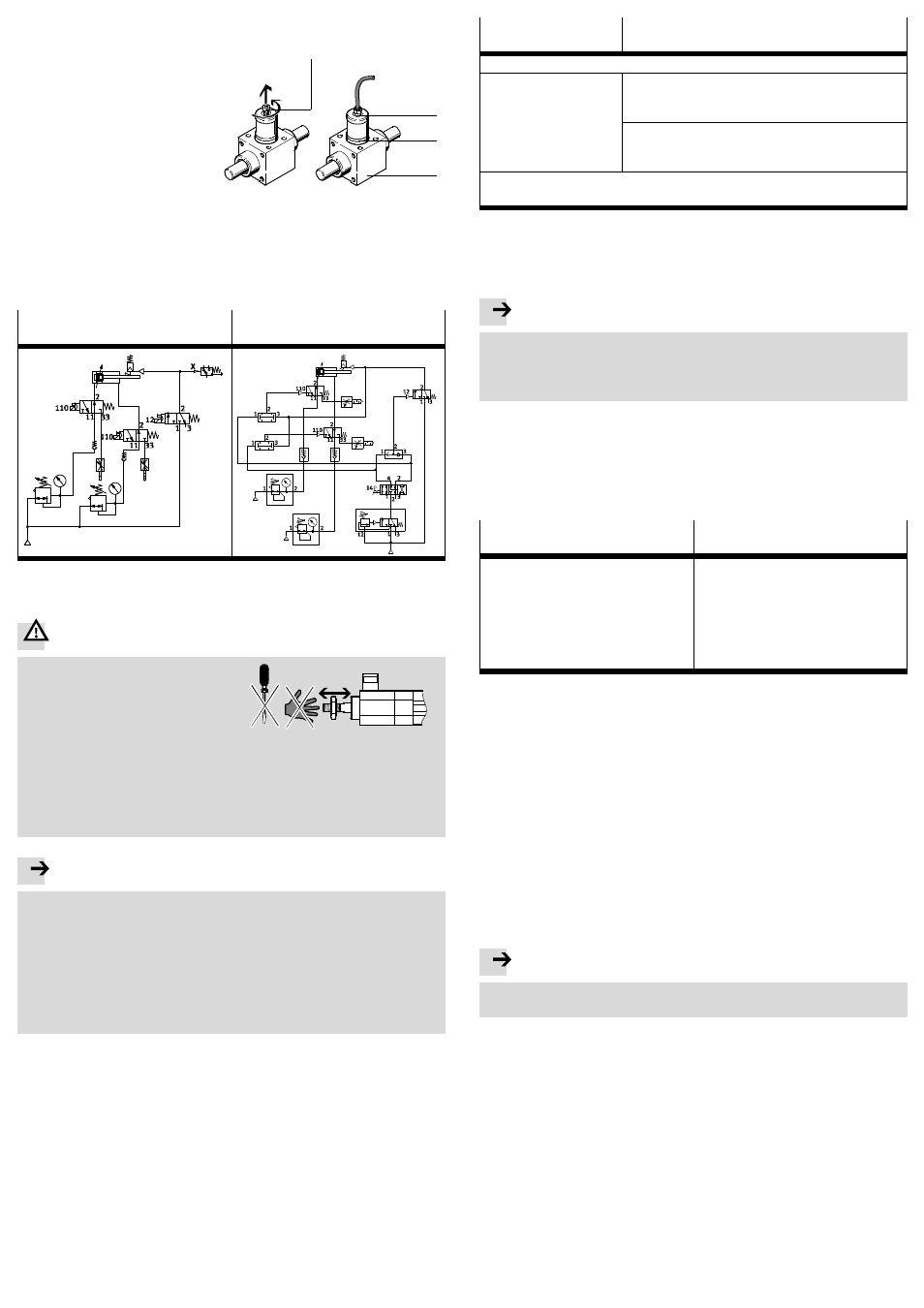

The following shows two examples of control circuits.

Clamping when there is a sudden

pressure failure

Moving to any desired position and

clamping

Fig. 13

4

Commissioning

Warning

Clamping rods can move out suddenly and

unexpectedly, thereby causing injury to

anybody who is in the positioning range.

• Make sure that:

– nobody reaches into the positioning

range of the moveable load

– no objects project into the danger

zone of the moving load

Fig. 14

– the clamping cartridge

2 is logically controlled in a correct manner

– no modifications may be made to the product.

Improper modifications impair the functioning and represent a safety risk.

Note

Clamping in movement sequences (braking) is not permitted. Increased wear

leading to complete failure is possible.

• Make sure that the dynamic holding force is always less than the static holding

force.

Apart from that, the clamping rod can break through.

• Make sure that the cylinder

8 is only pressurised in the park position when the

clamp is released.

Movement against a non-pressurised chamber will create an acceleration

which can damage the cylinder

8.

1. Slowly pressurise the complete system with at least 3 bar.

2. Exhaust the cylinder

8.

3. Completely screw in the adjusting screws on the cylinder

8 for the end-position

cushioning

6.

4. Start a test run as described in table Fig. 15.

5. End the test run.

Clamping cartridge

2/

clamping unit

5

Cylinder with clamping unit

8

Pressurise the supply port

1 on the clamping cartridge2 with 3 to max. 10 bar.

Move the clamping rod

4

in a longitudinal direc-

tion.

Pressurise both ports of the cylinder

8 slowly in

order to prevent danger caused by the piston rod

4

accelerating suddenly.

Adjust the pneumatic end-position cushioning by

means of the adjusting screws (not on cylinders with

elastomer cushioning).

Check the clamping function of the clamping rod

4 by exhausting the supply

port

1.

Fig. 15

5

Operation

The clamping rod

4 can only be moved if the clamping cartridge2 is pressurised

or if the mounting screw

9 is screwed in.

Note

Transverse loadings due to non-aligned guides lead to increased wear.

• Make sure the clamping rod

4 is only loaded in the direction of movement.

• Use a self-aligning rod coupler (

Accessories) in order to avoid transverse

forces.

5.1 Clamping during operation

1. Pressurise the supply port of the park position on the cylinder

8.

2. Exhaust the clamping cartridge

2 and then the cylinder8.

5.2 Moving out of a clamped parking position

Clamping cartridge

2/

clamping unit

5

Cylinder with clamping unit

8

1. Pressurise the supply port

1 on the

clamping cartridge

2 with 3 to

max. 10 bar.

2. Move the clamping rod

4 into the

desired position.

1. Pressurise the piston of the cylin-

der

8 on both sides.

2. Pressurise the supply port

1 on the

clamping cartridge

2 with 3 to

max. 10 bar.

3. Switch the directional control valve

for controlling the cylinder

8.

Fig. 16

5.3 Checking the clamping function of a cylinder with clamping unit

8:

• Check the clamping function on a regular basis and immediately after a sud-

den pressure failure. The piston rod should be located in a park position

when doing this.

Positioning the piston rod:

1. Pressurise the supply ports on the cylinder

8 on both sides.

2. Release the clamping function of the clamping cartridge

2 manually or pneu-

matically.

3. Exhaust one of the supply ports on the cylinder

8 and, in doing so, move the

piston rod

4 to a park position.

Checking to ensure a safe clamping function without an effective load:

1. Pressurise the cylinder

8 on the stroke side chamber so that the piston rod4 is

held securely in the park position.

2. Exhaust the clamping cartridge

2 to clamp the piston rod4.

3. Pressurise the cylinder

8 in the stroke direction.

Note

• Make sure that the maximum holding force of the clamping cartridge

2 is not

exceeded with the cylinder pressure.

The clamping function of the clamping cartridge

2 is fine if the piston rod4 only

moves slightly (

axial play in the chapter “Technical data”).

6

Maintenance and care

Cleaning:

1. Exhaust the cylinder

8 and the clamping cartridge2.

2. Clean the clamping unit and the clamping rod

4 with a soft cloth.

Avoiding unlubricated operation:

3. Lubricate the surface of the clamping rod

4 with a thin layer of grease.

• Use lubricating grease LUB-KC1 SILIKONFREI. The lubricating grease should

only be recognisable by a slight darkening of the surface due to the colour of

the grease.

• Recommendation: Apply the grease with a cloth or soft brush.