1 function and application, Kp, kpe, adn-…-kp, dnc-…-kp, dsbc-…-c, dsnu-…-kp – Festo DSNU-…-KP User Manual

Page 5

KP, KPE, ADN-…-KP, DNC-…-KP,

DSBC-…-C, DSNU-…-KP

Festo AG & Co. KG

Postfach

D-73726 Esslingen

+49 711 347 0

www.festo.com

Operating instructions

8003373

1205f

Original: de

Clamping cartridge, clamping unit,

cylinder with clamping unit

English

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Note

Installation and commissioning are to be carried out only by qualified personnel

in accordance with the operating instructions.

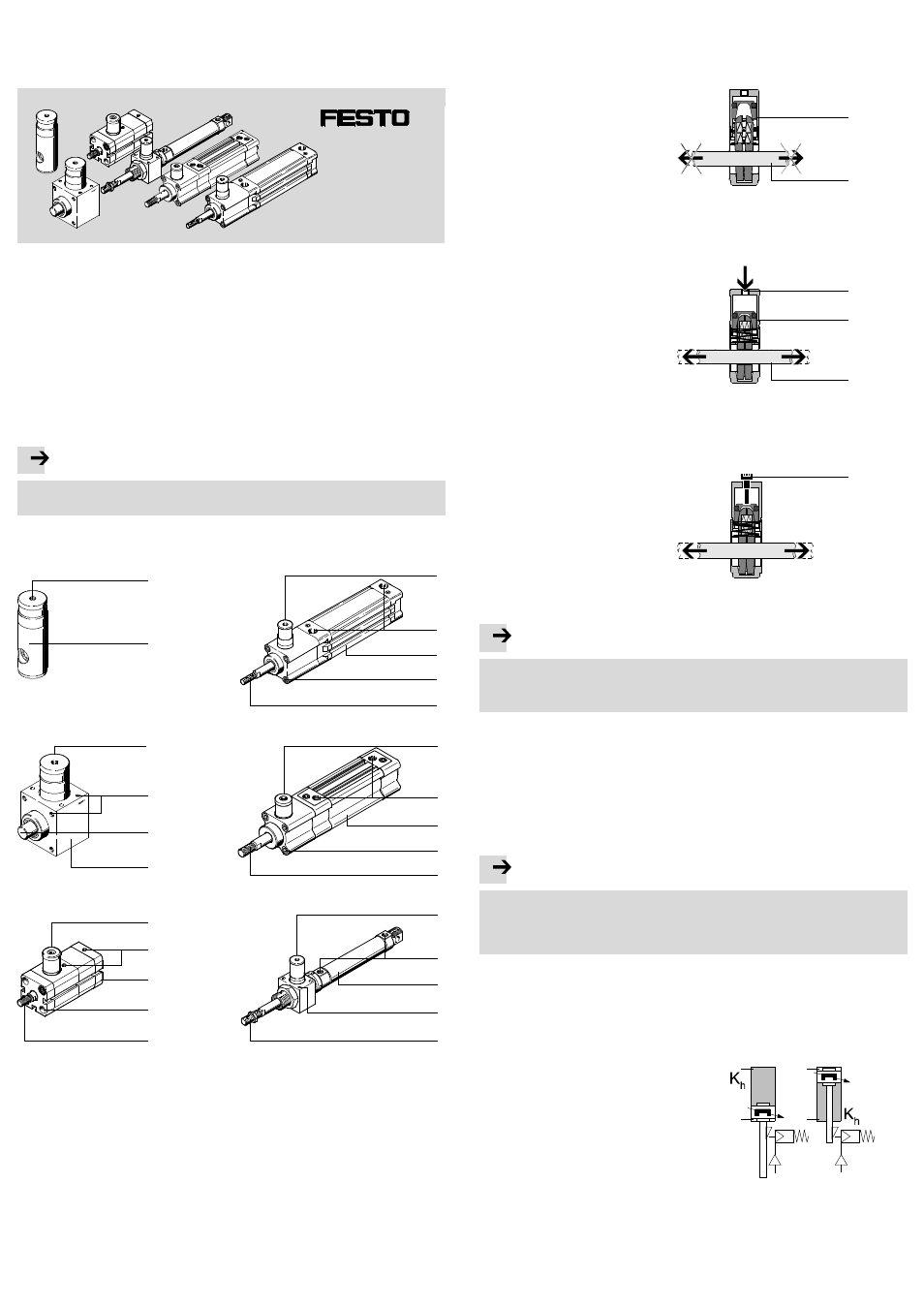

Control sections and connections

KP

1

2

3

4

5

KPE

DSNU-...-KP

4

6

8

DNC-...-KP

4

6

7

ADN-...-KP

6

7

4

DSBC-...-C

4

6

7

2

8

3

2

8

2

2

8

2

1 Thread for

– Supply port or

– Mounting screw

2 Clamping cartridge (KP or C char-

acteristic)

3 Holes and threads for mounting

4 Clamping rod (piston rod or round

material)

5 Clamping unit; housing for holding

the clamping cartridge

2

6 Supply port for cylinder (with ad-

justing screw for end-position

cushioning, if applicable)

7 Thread for mounting

8 Cylinder with clamping unit

Fig. 1

1

Function and application

The clamping cartridge

2 holds the clamping rod 4 (with effective load) firmly in

any position.

Clamping the clamping rod

4

When the clamping cartridge

2 is

exhausted, a spring presses the

clamping jaws apart. As a result of

the clamping jaws being pushed

apart, the jaws are tilted on the

clamping rod

4. The clamping rod

4 is clamped in a friction-locking

manner.

2

4

Fig. 2

Pneumatically releasing the

clamping rod

4

When the clamping cartridge

2 is

pressurised (supply port

1), a pis-

ton presses the clamping jaws to-

gether until the jaws are parallel to

each other. The holes in the clamp-

ing jaws then lie in an axis with the

clamping rod

4. The clamp is re-

leased.

Fig. 3

1

2

4

Manually releasing the clamping

rod

4

• Screw the supplied mounting

screw

9 (M5 DIN 912 or GÁ) in-

to the supply port

1 of the

clamping cartridge

2.

This presses the clamping jaws to-

gether over the piston until the

clamping is loosened.

Fig. 4

9

Note

The clamping cartridge

2 can be damaged when manually releasing the clamp.

• Only screw the mounting screw

9 into the supply port1 until the clamp is

released.

The clamping cartridge

2 is designed for holding a clamping rod4 (in most cases

a piston rod).

The clamping unit is intended for the following applications:

– Holding or clamping the clamping rod

4 in any position.

– Avoiding stroke movements:

– due to fluctuations in the operating pressure

– due to leakage on seals or tubing.

Note

Clamping in movement sequences (braking) is not permitted. Increased wear

leading to complete failure is possible.

• Make sure that the dynamic holding force is always less than the static holding

force.

If a pressure failure occurs (e.g. caused by an emergency switch off ), continued

use is only permitted after a subsequent functional test (

Operation). Except in

the event of sudden pressure failure, clamping may only be undertaken when the

cylinder is in the intermediate or end positions of the cylinder, referred to here as

the parking position.

• Only pressurise a clamped piston rod

4

that is resting in a park position in chamber

(K

h

) on the stroke side.

This is to prevent the piston from moving to

a non-pressurised chamber when clamping

is released.

Fig. 5