Operating instructions safety switches nz.h/p – EUCHNER NZ Safety switch User Manual

Page 4

Operating Instructions Safety Switches NZ.H/P

Correct use

Safety switches of type series NZ are used in control systems

that perform safety functions, e.g. for safety guards or as

position encoders.

The safety switches are positively driven auxiliary power swit-

ches and comply with the requirements as per IEC 60947-5-1

/ EN 60947-5-1 annex K.

In combination with a separating safety guard, this safety

device prevents dangerous machine movements from

occurring while the safety guard is open. A stop command is

triggered if the safety guard is opened during the dangerous

machine function.

Before safety switches are used, a risk assessment must be

performed on the machine in accordance with

EN ISO 13849-1, Safety of machinery. Safety related parts

of control systems. General principles for design

EN ISO 14121, Safety of machinery. Risk assessment.

Principles.

Correct use includes compliance with the relevant

requirements for installation and operation, particularly

EN ISO 13849-1, Safety of machinery. Safety related parts

of control systems. General principles for design

EN 1088, Safety of machinery. Interlocking devices

associated with guards. Principles for design and selection

EN 60 204-1, Electrical equipment of machines

Important:

The user is responsible for safe integration of the device in a

safe overall system. For this purpose, the overall system must

be validated, e.g. in accordance with EN ISO 13849-2.

If the simplified method according to section 6.3 EN ISO

13849:2008-12 is used for validation, the Performance

Level (PL) may be reduced if several devices are connected

one after the other.

If a product data sheet is included with the product, the

information on the data sheet applies in case of

discrepancies with the operating instructions.

Safety precautions

Safety switches fulfill a personal protection function. Incorrect

installation or tampering can lead to severe injuries to

personnel.

Safety components must not be bypassed (bridging of

contacts), turned away, removed or otherwise rendered

ineffective.

On this topic pay attention in particular to the measures

for reducing the possibility of bypassing according to

EN 1088:1995.A2:2008, sec. 5.7.

Safety switches and trip dogs must be arranged such

that they are adequately secured against movement.

To meet these requirements:

The fixings must be reliable and must also require the use

of a tool to undo them.

The use of slots must be limited to the initial adjustment.

Precautions must be taken to ensure that there is no

movement after adjustment (e.g. using bolts or dowel

pins).

Mounting, electrical connection and setup only by

authorized personnel.

Function

See travel diagram.

Mounting

The safety switches must not be used as a mechanical

end stop.

The actuator (lever arm) must be positively mounted to the

actuating shaft. The square drive on the actuator and

actuating shaft must engage with each other (see Figure 1).

To ensure correct operation, the trip dogs must be fitted

so that the actuator is deflected by at least an angle of

45°

+5°

(achievement of the stipulated contact opening,

see Figure 7 and 8).

Safety switches must be attached and, if necessary,

protected in such a way that predictable damage can be

avoided.

It must be ensured that safety switches are accessible

for maintenance and function tests.

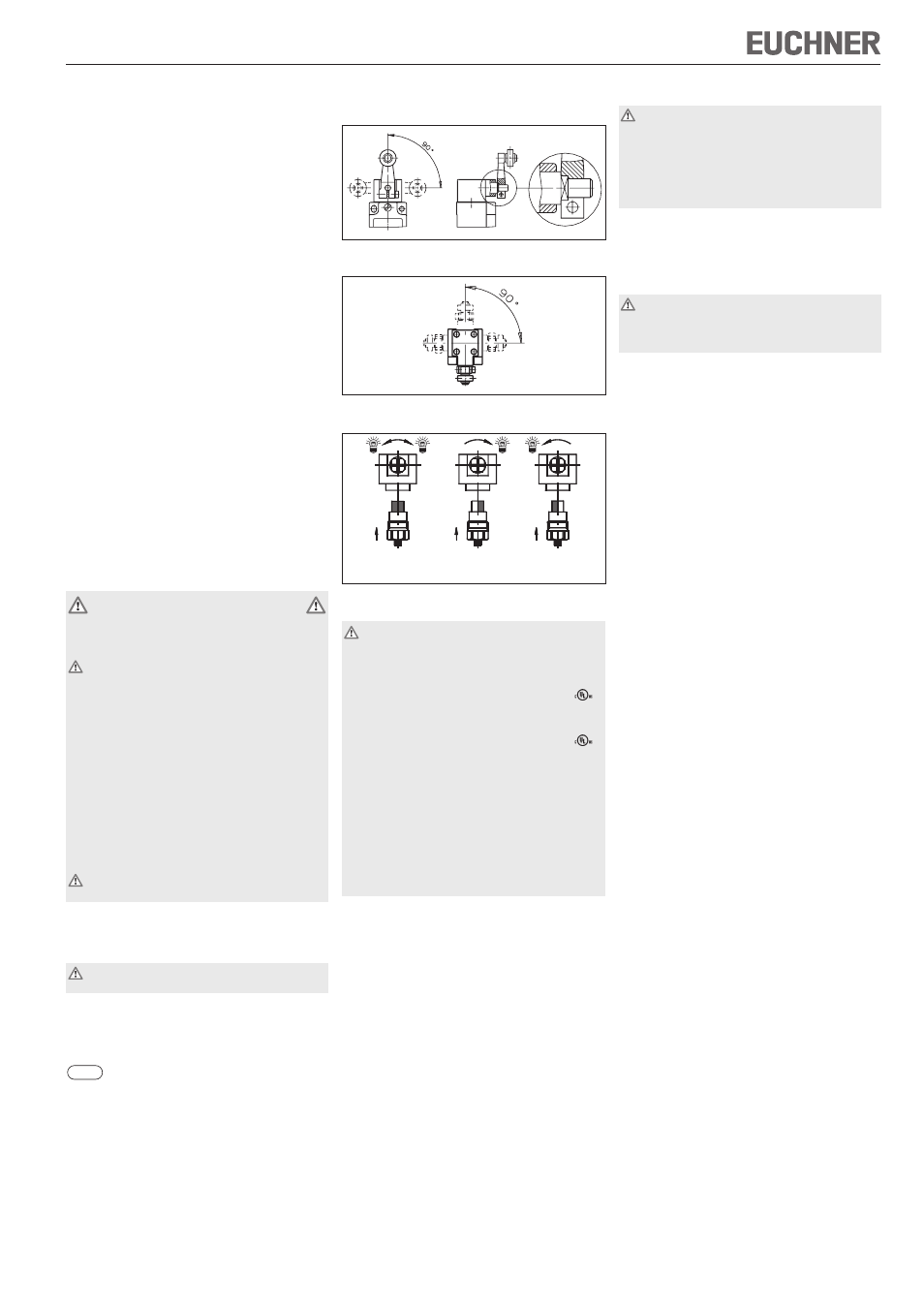

Adjustment options

Vertical actuator adjustment 4 x 90° (positive mounting)

Fig. 1: Vertical actuator adjustment

Horizontal adjustment 4 x 90°

Fig. 2: Horizontal adjustment

Switching direction change with lever arm actuation

Fig. 3: Changing the switching direction

Electrical connection

When choosing the insulation material and wire for the

connections, pay attention to the over-temperature in

the housing (depending on the operating conditions)!

For NZ1:

For use and applications as per the requirements of

, a

rigid copper wire 60/75 °C is to be used.

For NZ2:

For use and applications as per the requirements of

, a

class 2 power supply or a class 2 transformer according to

UL1310 or UL1585 must be used.

Connection cables for safety switches installed at the place

of use must be separated from all moving and permanently

installed cables and un-insulated active elements of other

parts of the system which operate at a voltage of over 150

V. A constant clearance of 50.8 mm must be maintained.

This does not apply if the moving cables are equipped with

suitable insulation materials which possess an identical or

higher dielectric strength compared to the other relevant

parts of the system.

Version NZ1... (cable entry)

Fit cable gland M20 x 1.5 with appropriate degree of

protection.

Conductor cross-section 0.34 ... 1.5 mm².

For terminal assignment see Figure 6.

Tighten screws for connections to 0.5 Nm (1 Nm on

ES511).

Check that the cable entry is sealed.

Close switch cover and tighten screws to 1.2 Nm.

Version NZ2... (plug connector SR6)

Conductor cross-section 0.5 ... 1.5 mm².

For connector assignment see Figure 6a.

Version NZ2... (plug connector SR11)

Conductor cross-section 0.5 mm².

For connector assignment see Figure 6b.

Version NZ2... (plug connector M12/SVM5)

Conductor cross-section 0.34 mm².

For connector assignment see Figure 6c.

Functional check

When the safety guard is open, the safety switch must

be actuated in any safety guard position (overrun

protection).

In safety circuits, check the safety function.

The machine must stop when the safety switch is actuated.

The machine must not start when the safety switch is

actuated.

Mechanical function test

Check the actuating element for freedom of movement.

Electrical function test

Actuate switch and check the switching function.

Inspection and service

If damage or wear is found, the complete switch and

actuator assembly must be replaced.

Replacement of individual parts or assemblies is not

permitted!

No servicing is required, but regular inspection of the

following is necessary to ensure trouble-free long-term

operation:

correct switching function

secure mounting of components

dirt and wear

sealing of cable entry

loose cable connections or plug connectors.

Note:The year of manufacture can be seen in the bottom,

right corner of the rating plate.

Exclusion of liability under the following

circumstances

incorrect use

non-compliance with safety regulations

installation and electrical connection not performed by

authorized personnel.

failure to perform functional checks.

EC declaration of conformity

The manufacturer named below herewith declares that the

product fulfills the provisions of the directive(s) listed below

and that the related standards have been applied.

EUCHNER GmbH + Co. KG

Kohlhammerstraße 16

70771 Leinfelden-Echterdingen, Germany

Directives applied:

Machinery directive 2006/42/EC

Standards applied:

EN 60947-5-1:2004 + Cor.:2005 + A1:2009

EN 1088:1995+A2:2008

Leinfelden, July 2010

Dipl.-Ing. Michael Euchner

Director

Duc Binh Nguyen

Authorized representative empowered to draw up

documentation

The signed EC declaration of conformity is included with

the product.

Left / right

Right switching

Left switching

switching

(standard position)