Enerpac WCR-Series User Manual

Page 8

Fig. I

8

ENGLISH

4 Operation

4.1 Prior to operation

-

Make sure the nut or bolt to be

fastened is clean and free of dust.

-

Make sure the nut or bolt runs

correctly on the thread.

-

Make sure that the threads and the

bearing surface are liberally coated

with the correct lubricant or anti-

seizure compound.

-

Make sure that the spanner used to

keep the nut or bolt on the opposite

end in place, is of the correct size

and that there is an adequate

abutment surface.

4.2 To set the torque

Adjust the pressure on the pump as

necessary to set the torque. Refer to sections

6.3.1 and 6.3.2 for torque setting tables.

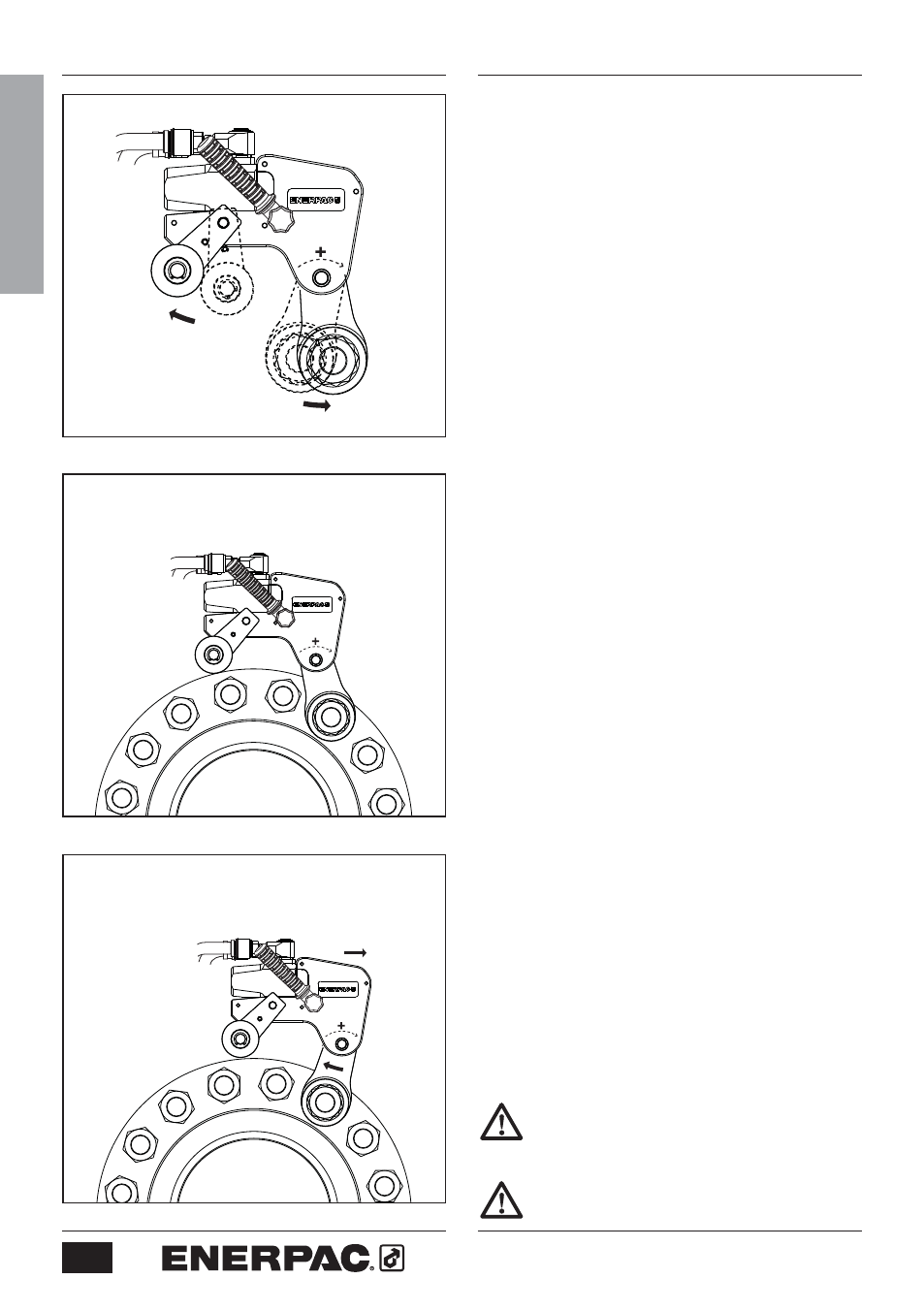

4.3.1 To tighten a nut or bolt (fig. G, H, I)

•

Place the wrench on the ground or on

a solid surface, such as a workbench.

•

Operate the pump in the Retract

direction until drive unit is fully

retracted and the spanner socket

moves fully outward. Stop the pump.

•

Swing the reaction roller bracket fully

outward, away from center of tool.

•

Position the tool on the nut (bolt) with

the clockwise (+) side facing upwards.

•

Position reaction roller against pipe

flange. Note: If a gap between

roller and flange is present, position

the roller as close to the flange as

possible, so that gap is minimal.

•

Operate the pump in the Advance

direction to activate the wrench and

begin tightening the nut (bolt).

Stop operation immediately if a gap

appears between the cylinder

locating plate and the drive unit.

Never strike the tool with a hammer.

Fig. H

Fig. G