Enerpac WCR-Series User Manual

Page 10

10

ENGLISH

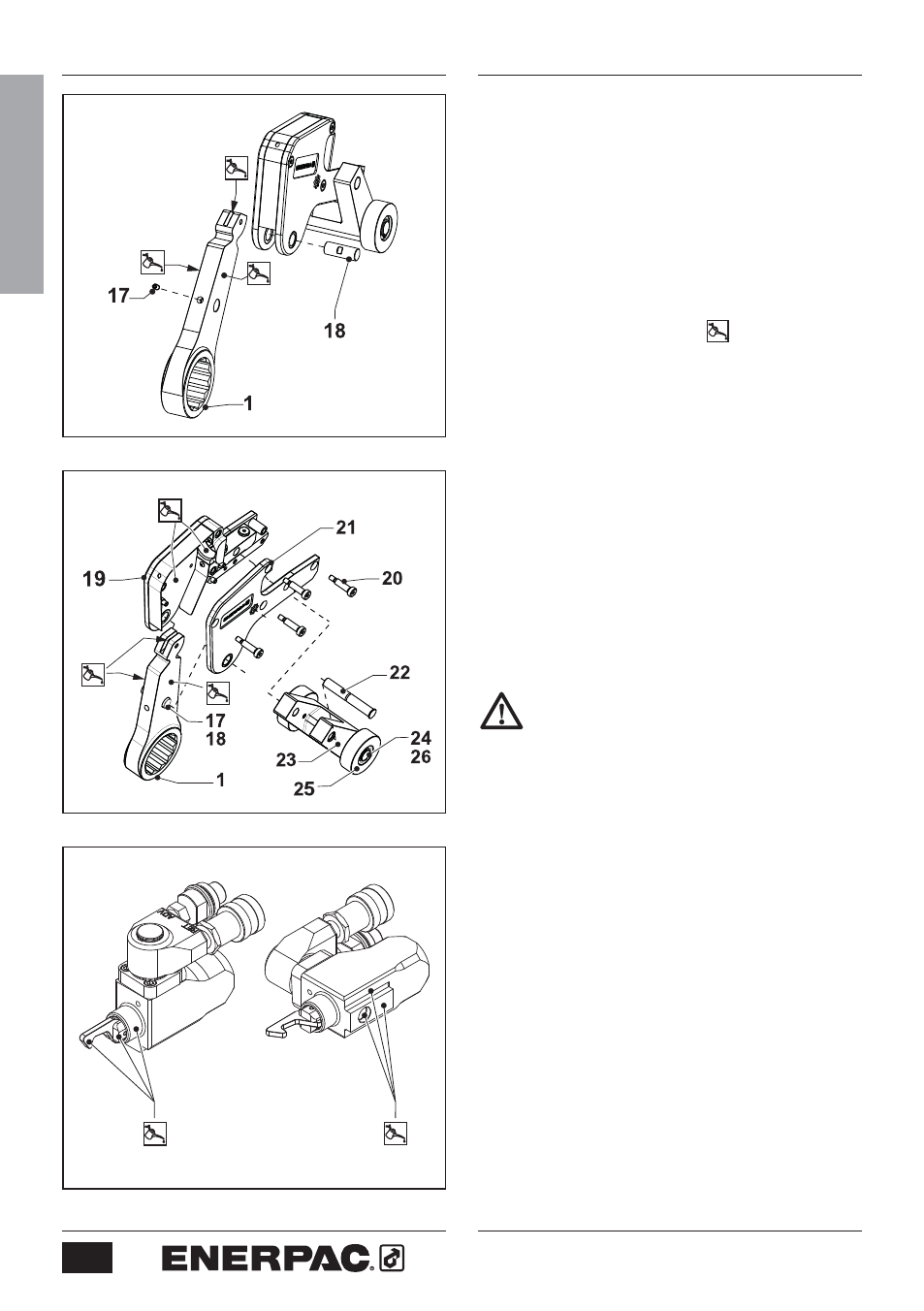

Fig. O

5

Maintenance and troubleshooting

5.1 Spanner replacement (Fig M)

•

Remove drive unit from cassette.

•

Loosen and remove

set

screw (17).

• Tap

spanner

pin (18) on one end and

remove it from the cassette.

•

Slide spanner (1) out of cassette

housing.

•

Apply a thin coat of molybdenum

disulphide lubricant

to the sides

of the new spanner and to the

spring

pin

at top of spanner.

•

Slide new spanner (1) into cassette

housing. Align hole in spanner with

mating holes in sideplates.

• Install

spanner

pin (18) through holes.

Before installation, be sure that flat

area of pin is aligned with

set

screw

hole in spanner.

•

Apply a small amount of Loctite 243

to threads of

set

screw (17).

• Reinstall

set

screw (17).

5.2 Preventative maintenance (Fig N & O)

Preventative maintenance can be

carried out by the user. Full

maintenance must be carried out by

an approved and authorized

technician appointed by Enerpac.

Recommended service intervals are:

a) 3 months – Heavy Duty use

b) 6 months – Normal use

c) 12 months – Infrequent use

-

Non destructive testing must be

carried out if the tool has been used

under severe conditions.

5.2.1 The roller cassette

•

Remove drive unit from cassette.

• Remove

the shoulder screws

(20). Lift

and remove the sideplate (21).

•

Remove spanner (1),

spanner

pin (18)

and

set

screw (17) as an assembly.

• Remove

reaction

roller bracket

pin

(22) and reaction roller bracket (23).

Fig. N

Fig. M