Enerpac W-Series User Manual

Page 9

ENGLISH

9

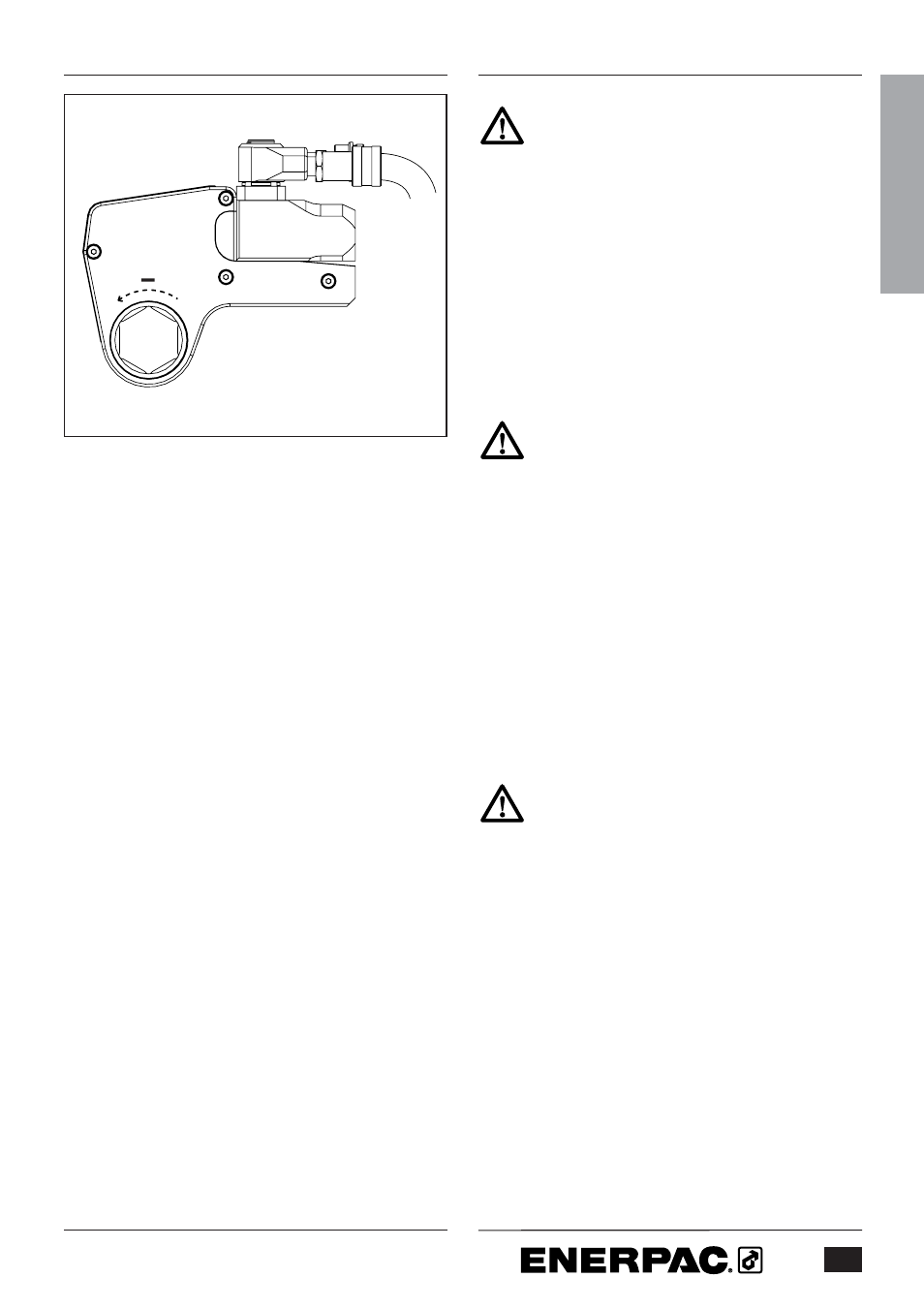

Fig. G

Stop operation immediately if a gap

appears between the cylinder

locating plate and the drive unit.

4.3.2 To loosen a nut or bolt (fig. G)

•

Apply releasing oil to the threads.

Allow the oil to soak.

•

Position the tool on the nut or bolt

with the anti-clockwise (-) side facing

upwards.

•

Operate the pump until the nut or bolt

is loose.

If the nut or bolt will be re-used avoid

excess load when loosening.

-

Be aware that when loosening a nut

or bolt more torque is usually required

than when tightening.

-

Humidity corrosion (rust) requires up

to twice the torque required for

tightening.

-

Sea water and chemical corrosion

requires up to two and a half times

the torque required for tightening.

-

Heat corrosion requires up to three

times the torque required for

tightening.

Be aware that when loosening a nut

or bolt shock loading can occur. Do

not apply more than 75% of the

wrench’s maximum torque when

loosening nuts or bolts.

- MS-Series hoses (32 pages)

- А-Series (28 pages)

- WR-Series (24 pages)

- NS-Series (92 pages)

- NC-Series (39 pages)

- FSH-Series (56 pages)

- GT-Series (134 pages)

- HXD-Series (172 pages)

- SQD-Series (140 pages)

- W22000 (28 pages)

- S-Series (264 pages)

- E-Series (70 pages)

- WCR-Series (20 pages)

- ATM-2 (92 pages)

- ATM-9 (136 pages)

- ATM-4 (136 pages)

- FF-Series (164 pages)

- VE-Series (24 pages)

- MRS-Series (4 pages)

- LU-Series (6 pages)

- CY Series (2 pages)

- MRH-Series (52 pages)

- CYDA-Series (2 pages)

- ECH-Series (36 pages)

- PT-Series (32 pages)

- BS-Series (32 pages)

- CSM-Series (66 pages)

- WFM-72 (48 pages)

- WFL-442 (60 pages)

- WFL-112 (40 pages)

- WFC-222 (32 pages)

- SafeLink (16 pages)

- ASC-Series (4 pages)

- CAC-Series (44 pages)

- SC-1 (4 pages)

- SC-3 (2 pages)

- SU-121 (12 pages)

- SU-352 (52 pages)

- SU-52 (48 pages)

- SC-Series (64 pages)

- SU7-Series (12 pages)

- LU7-Series (8 pages)

- PTJ-Series (12 pages)

- STB-Series (48 pages)