Enerpac А-Series User Manual

Page 3

3

CAUTION: Be sure threads are fully engaged. All loads

must be transferred to the face of the plunger. Threads

will be stripped if loaded.

5.0 OPERATION

Refer to the instruction sheet supplied with your pump for

information on installing and operating your pump.

1. Check the oil level in the pump.

2. Make sure all connections are tight and leak free.

3. Remove air from the system by placing the cylinder at a lower

level than the pump and cycling the cylinder several times

until the motion is smooth.

IMPORTANT: Do not exceed the maximum system pressure for

the spreader model being used:

Model A-92: Maximum system pressure must not exceed 5,000

psi (344 bar). Spreader maximum capacity is achieved at 50

percent of the RC-10 cylinder's rated maximum pressure.

Model WR-15: Maximum system pressure varies depending on

spread distance. Refer to WR-15 load ratings table in Section

3.0.

Model WR-5: Maximum system pressure must not exceed

10,000 psi (689 bar).

WARNING: Failure to observe pressure limits may

result in serious personal injury and/or damage to

spreader.

CAUTION: Pressurizing the spreader with the jaws in

the fully open position can damage the spreader and

may result in failure of spreader components.

4. Operate the pump to spread the cylinder jaws. The jaws will

close automatically when the pressure is released. The

speed of retraction is dependent on the length of the hose

and other restrictions in the line.

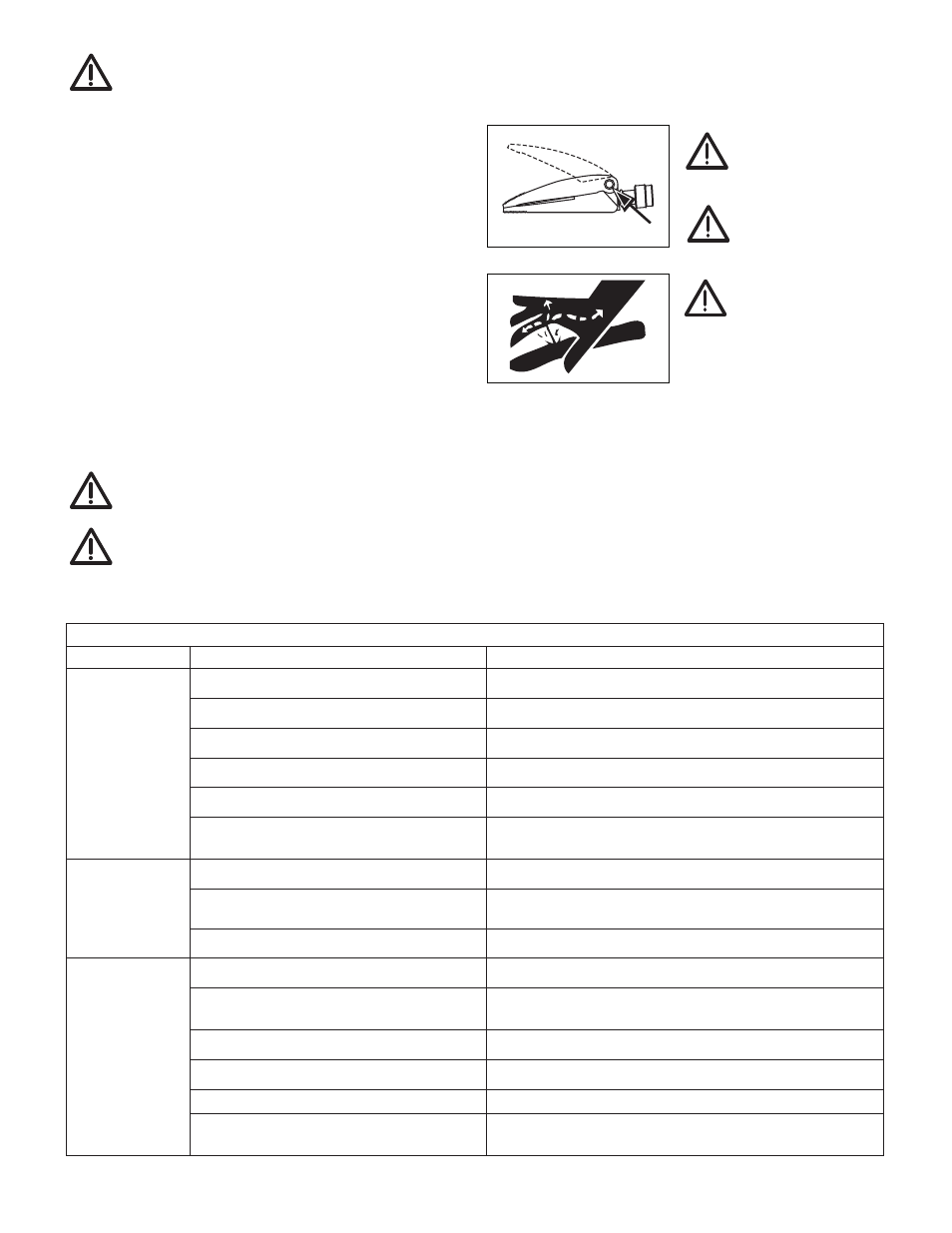

CAUTION: Keep

hands away from the

pivot point (A) of

spreader jaws.

CAUTION: Keep

hands clear of the

load, away from the

jaws of the spreader.

W

ARNING: DO NOT

handle pressurized

hoses. Escaping oil

u n d e r pressure can penetrate

the skin, causing serious injury.

If oil is injected under the skin,

see a doctor immediately.

6.0 MAINTENANCE

Use dust caps on couplers when cylinders are disconnected to

prevent dirt from entering the system. Keep parts clean. Inspect

all components for damage or wear before and after use.

7.0 TROUBLESHOOTING

The following information is intended as an aid in determining

if a problem exists. For repair service, contact the Authorized

Enerpac Service Center in your area.

Troubleshooting

Problem

Possible Cause

Solution

Cylinder does

not advance,

advances slowly,

or advances in

spurts.

Oil level in pump reservoir is low.

Add oil according to the pump instructions.

Pump release valve open.

Close pump release valve.

Loose hydraulic coupler.

Check that all couplers are fully tightened.

Load is too heavy.

Do not attempt to lift more than rated tonnage.

Air trapped in system.

Remove air according to the instructions above.

Cylinder plunger binding.

Check for damage to cylinder.

Have cylinder serviced by a qualifi ed hydraulic technician.

Cylinder

advances, but

does not hold

pressure.

Leaking connection.

Check that all connections are tight and leak free.

Leaking cylinder seals.

Locate leak(s) and have equipment serviced by a qualifi ed

hydraulic technician.

Internal leakage in pump.

Have cylinder serviced by a qualifi ed hydraulic technician.

Cylinder does

not retract,

retracts part

way, or retracts

more slowly than

normal.

Pump release valve closed.

Open pump release valve.

Pump reservoir is over-fi lled.

Drain oil level to full mark.

See pump instructions for adding oil.

Loose hydraulic coupler.

Check that all couplers are fully tightened.

Air trapped in system.

Remove air according to the instructions above.

Hose I.D. too narrow.

Use larger diameter hydraulic hose.

Cylinder retraction spring broken or other

cylinder damage.

Have cylinder serviced by a qualifi ed hydraulic technician.

A