Enerpac А-Series User Manual

Page 2

2

DANGER: Do not handle pressurized hoses. Escaping

oil under pressure can penetrate the skin, causing

serious injury. If oil is injected under the skin, see a

doctor immediately.

WARNING: Only use hydraulic cylinders in a coupled

system. Never use a cylinder with unconnected couplers. If

the cylinder becomes extremely overloaded, components

can fail catastrophically causing severe personal injury.

WARNING: BE SURE SETUP IS STABLE BEFORE

LIFTING LOAD. Cylinders should be placed on a fl at

surface that can support the load. Where applicable, use

a cylinder base for added stability. Do not weld or otherwise

modify the cylinder to attach a base or other support.

Avoid situations where loads are not directly centered

on the cylinder plunger. Off -center loads produce

considerable strain on cylinders and plungers. In

addition, the load may slip or fall, causing potentially dangerous

results.

Distribute the load evenly across the entire saddle surface.

Always use a saddle to protect the plunger.

IMPORTANT: Hydraulic equipment must only be serviced

by a qualifi ed hydraulic technician. For repair service,

contact the Authorized ENERPAC Service Center in your

area. To protect your warranty, use only ENERPAC oil.

WARNING: Immediately replace worn or damaged parts

by genuine ENERPAC parts. Standard grade parts will

break causing personal injury and property damage.

ENERPAC parts are designed to fi t properly and withstand high

loads.

3.0 SPECIFICATIONS

Load Ratings for WR-5

Maximum System

Pressure

psi (bar)

Maximum Rated Load

at Tips

lbs. (kg)

10,000 (689)

2,000 (907)

Load Ratings for WR-15

Spread at Tips

in. (cm)

Maximum System

Pressure

psi (bar)

Maximum Rated Load

at Tips

lbs. (kg)

0 (0)

9,000 (620)

1,500 (682)

3 (8)

9,000 (620)

6 (15)

6,000 (415)

9 (23)

3,000 (205)

11.5 (29)

1,000 (70)

Load Ratings for A-92

Cylinder Required

(Note: cylinder

sold separately)

Maximum System

Pressure

psi (bar)

Maximum Rated

Load at Tips

lbs. (kg)

Enerpac RC-10 Series

(All models except RC-101)

5,000 (344)

2,000 (907)

4.0 INSTALLATION

WARNING: DO NOT USE the spreader on pipe fl anges

or in applications where one or both objects can move

in a circular or orbital motion. General purpose

spreader arms open in a radial motion and the spreader could

become a projectile if circular or orbital motion also occurs.

WR-5 and WR-15

Attach hose to 3/8" NPT port. Connect mating coupler halves

together hand tight only. Using tools will damage the coupler.

CAUTION: Position hoses to avoid sharp bends,

kinks, and sharp impacts from objects because they

may cause wear or damage to the hose, leading to

premature failure.

A-92

Attach an included A-13 or A-102F smooth saddle to the cylinder

plunger before attaching the spreader to the cylinder collar

threads. Hand tighten the saddle and the spreader.

IMPORTANT: An Enerpac RC-102 cylinder is recommended for

use with the spreader. However, an RC Series cylinder of longer

stroke (RC-104 through RC-1014) can be used if an RC-102

cylinder is not available. The RC-101 cylinder should not be used

because its stroke length is insuffi

cient for use with the spreader.

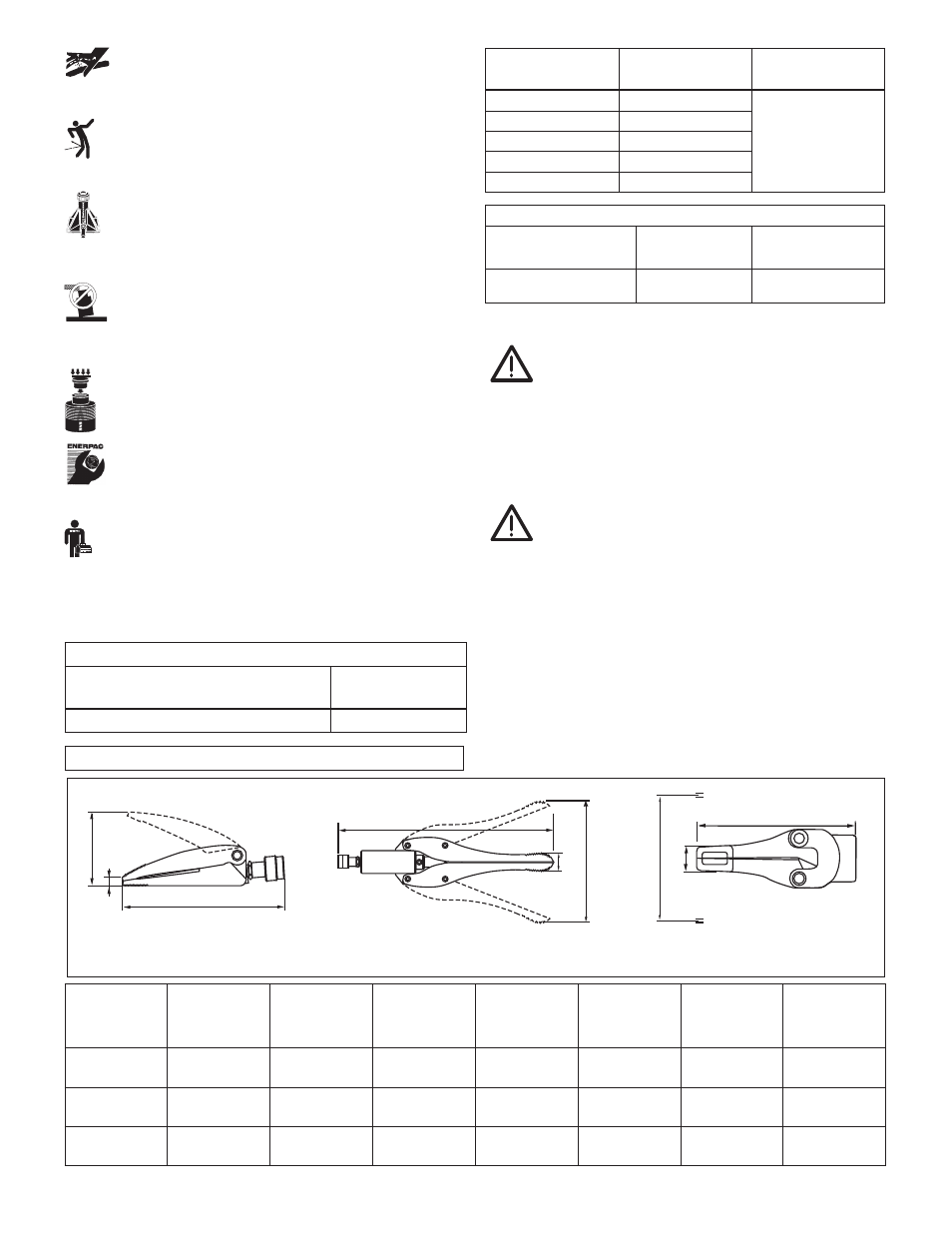

Model

No.

Capacity

Tons

Eff ective

Area

in2 (cm2)

A

in. (cm)

B

in. (cm)

C

in. (cm)

Oil

Capacity

in3 (cm3)

Wt.

lbs. (kg)

WR-5

1.00

1.00

(6,45)

8.78

(22,3)

3.70

(9,40)

0.38

(0,97)

0.61

(10,0)

5.00

(2,27)

WR-15

0.75

2.25

(14,5)

21.7

(55,0)

11.50

(29,21)

1.26

(3,20)

3.91

(64,1)

25.00

(11,34)

A-92

1.00

---

9.63

(24,5)

6.25

(15,88)

1.38

(3,51)

---

8.00

(3,63)

% &

$

%

&

$

%

&

$

:5

$

:5