Enerpac TQ-700E User Manual

Page 7

7

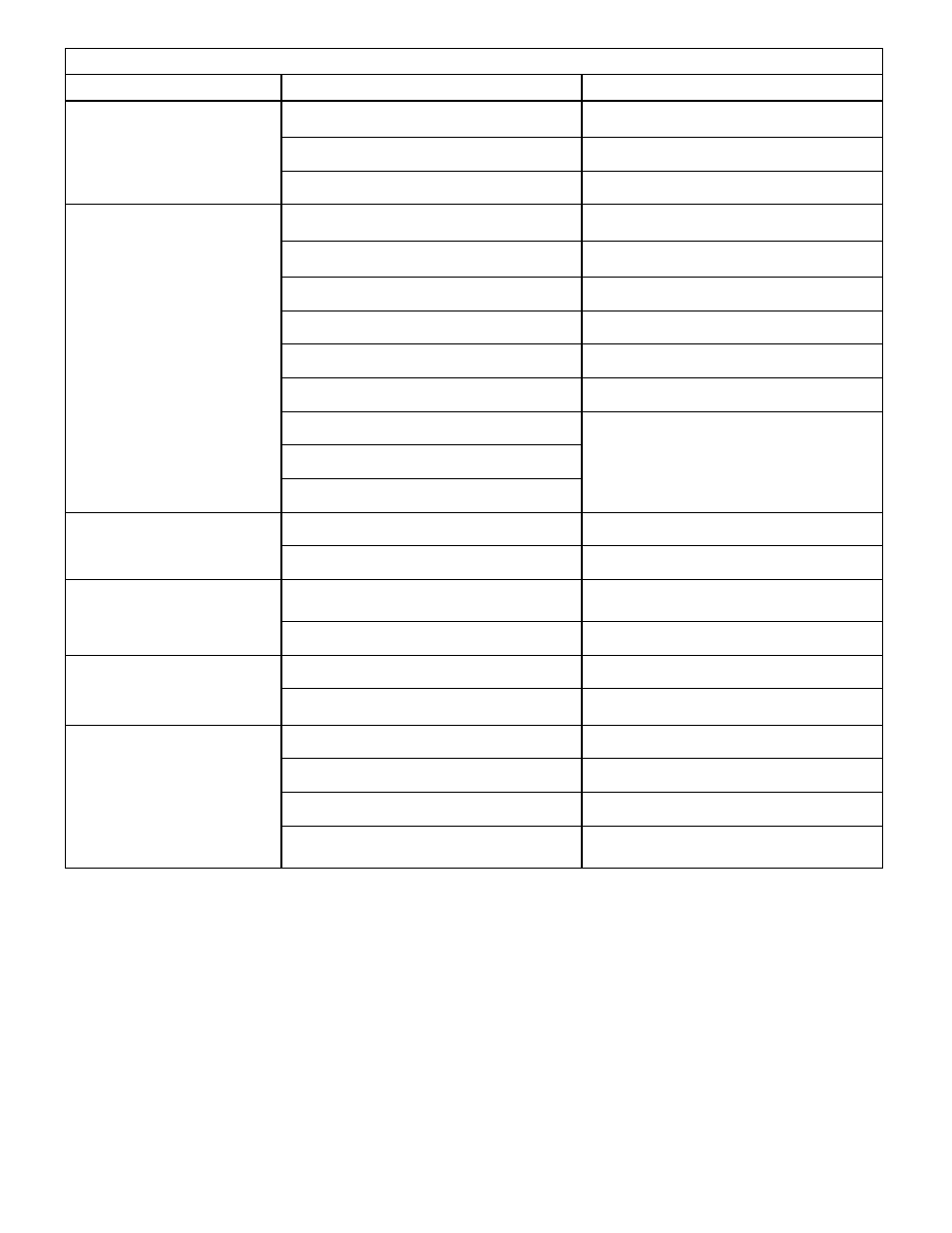

Troubleshooting Guide (continued)

Problem

Possible Cause

Action

Electric valve will not operate.

No power to pump or wrong voltage.

Connect to correct power source per pump

nameplate.

Solenoid cable disconnected or damaged.

Connect, repair, or replace cable.

Solenoid coil not operational.

See authorized service center.

Pump runs but will not pump oil.

or

Pump will not build full pressure.

Pump is not primed.

Run pump for a few minutes while tipping it gently

from side to side.

Reservoir breather not installed.

Remove shipping plug and install breather per

Section 4.1.

Low oil level.

Add oil per Section 4.2.

Relief valve pressure set too low.

Adjust per Section 5.6.

External system leak.

Inspect and repair or replace parts as required.

Oil intake screen clogged.

Clean oil intake screen.

Internal leak in pump.

See authorized service center.

Internal leak in valve.

Internal leak in system component.

Pump builds full pressure, but torque

wrench does not advance.

Torque greater than wrench capacity at full pressure.

Use torque wrench with larger capacity.

Advance fl ow line to wrench restricted or blocked.

Check couplers for full engagement per Section 4.4.

Torque wrench will not retract.

Return fl ow line from wrench restricted or blocked.

Check couplers for full engagement per Section 4.4.

Run motor when retracting.

Valve malfunction.

See authorized service center.

Pressure gauge does not read zero

(0) psi/bar when pump motor is

stopped.

Pressure not relieved.

Relieve pressure per Section 5.4.

Pressure gauge is out of calibration.

Have pressure gauge re-calibrated by a qualifi ed

calibration facility.

Pump runs hot.

Advance or retract fl ow restricted.

Check couplers for full engagement per Section 4.4

Low oil level.

Add oil per Section 4.2.

Oil cooler fan not working.

Check oil cooler fan for proper operation.

Oil cooler heat exchanger covered with dirt or

clogged.

Remove any dirt from oil cooler fi ns and fan.

Check oil cooler tubing for clogs.