Det-Tronics U7652B, C Unitized UV/IR Flame Detector User Manual

Page 13

When manual

oi

is selected, the detector is tested

either by pressing and holding the manual

oi

button

(if installed) or by shining a W867 Test Lamp into the

detector viewing windows. The “Startup and

Checkout Procedure (Manual

oi

Test)” section of this

manual explains this procedure. For problems

encountered during the manual

oi

test, refer to Table

6 - Manual

oi

Troubleshooting.

AUTOMATIC

oi

SELECTED

The Automatic

oi

feature (if selected) tests the detec-

tor approximately once each minute, checking the

cleanliness of the optical surfaces, sensor sensitivity,

and proper functioning of the electronic circuitry.

Proper operation of the detector is indicated by simul-

taneous blinking of both the UV and IR sensor LEDs

every 5 seconds. If a problem is detected for three

consecutive automatic

oi

tests, a fault signal is gen-

erated. If the detector passes three consecutive

automatic

oi

tests, the fault signal will then be

cleared. If a detector fault is indicated, observe the

detector LEDs as well as the status of the detector

relays, then refer to Tables 1 and 7 for status and

troubleshooting information.

Perform the “Startup and Checkout Procedure

(Manual

oi

Test)” in this manual to verify the proper

operation of the Fire relay and LEDs.

FIELD TESTING UV/IR DETECTORS

Det-Tronics UV/IR flame detectors contain sensitive

electronic components (ICs, transistors, etc.) that can

be damaged by electrostatic discharge (ESD).

Common causes of damage include improper han-

dling during installation/service, ground faults, power

supply transients, and lightning strikes. All Det-

Tronics systems are designed with extensive protec-

tion circuitry, however, damage can still occur.

The following field test procedure has been devel-

oped to test Det-Tronics UV/IR flame detectors for

ESD-damaged components:

1.

Disable (bypass) all automatic fire extinguishing

and shutdown equipment prior to testing. If the

detector is part of a Det-Tronics controller-based

system, simply move the controller key switch to

the Test mode.

11

95-8385

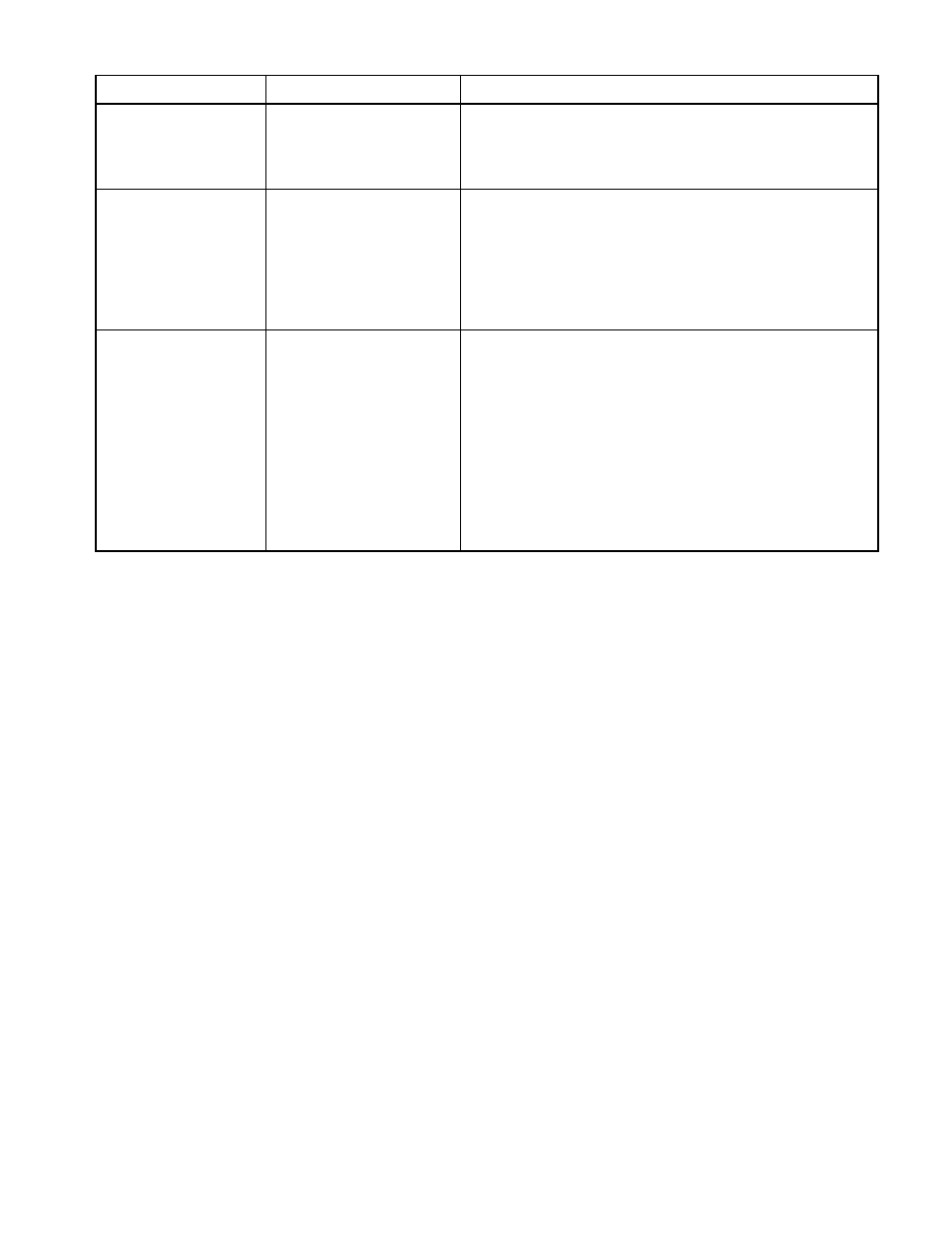

Condition

Indication

Corrective Action

Normal operation with

Fault relay de-energized

Check the operation of the power source and the

manual

oi

test not

LEDs not blinking

continuity of the detector wiring. If the detector appears

initiated

to be “dead” with power applied, remove power and

(Manual

oi

Selected)

replace the motherboard.

Manual

oi

Test

Fire relay did not energize

The other sensor has failed to respond.

and the LEDs of only one

• Check the cleanliness of the viewing window and

sensor are illuminated

repeat the test.

• If the sensor fails to respond again, replace the sensor

module.

• If the sensor still does not respond, replace the

motherboard.

Manual

oi

Test

Fire relay did not energize

Both sensors have failed to respond.

and the LEDs of neither

• Check input power and external wiring.

sensor are illuminated

• Check the cleanliness of both viewing windows.

If the detector still does not respond:

• If using a test lamp, check the battery, window, etc. to

be sure that the test lamp is working properly.

• If using the manual

oi

switch, check the switch for

proper operation and wiring.

If the detector still does not respond, replace the

motherboard.

Table 6—Manual

oi

Troubleshooting