Det-Tronics U7652B, C Unitized UV/IR Flame Detector User Manual

Page 12

In addition, the auxiliary relay in the U7652C can be

set for actuation by either “UV radiation only” or “both

UV and IR radiation” (indoor applications only).

Detector programming is accomplished using jumper

plugs at pin locations W1, W2, W3 and W4 on the

printed circuit board located inside the detector junc-

tion box. See Figure 4 to locate the pins.

Refer to Table 5 to determine whether the jumper plug

should be installed or omitted for a desired option.

The detector is furnished from the factory with the

jumpers “removed” (the jumper is connected to only

one of the two pins). This programs the detector for

the following:

— Latching alarm output

— Automatic

oi

testing

— Three second response time.

To change the programming of the detector, remove

the junction box cover by loosening the six screws

(without power applied), then position the jumpers as

desired.

STARTUP AND CHECKOUT

PROCEDURE (MANUAL

oi

TEST)

The following procedure should be performed when

installation is complete and, at minimum, every six

months. More frequent checkouts ensure greater

system reliability.

1.

Disable any extinguishing equipment that is con-

nected to the system.

2.

Apply input power to the system. (Wait ten sec-

onds after applying power before testing the sys-

tem.)

3.

Shine a Det-Tronics model W867 UV/IR test lamp

into the viewing window of the detector under

test, or press and hold the manual

oi

test button if

one has been wired into the system. The Fire

relay will energize and the LEDs will be illuminat-

ed when the device goes into an alarm condition.

4.

Turn off the UV/IR source (or release the

oi

test

button). If the unit is programmed for non-latch-

ing operation, the Fire relay will become de-ener-

gized and the LEDs will turn off when the UV/IR

source is removed. If the unit is programmed for

latching operation, it can be reset by removing

input power (0.1 second minimum).

5.

Repeat this test for all detectors in the system. If

a unit fails the test, refer to Table 6, Manual

oi

Troubleshooting, for information on correcting the

problem.

6.

Double check all detectors in the system to be

sure that they are properly aimed at the potential

hazard.

7.

Re-activate all extinguishing equipment that is

connected to the system.

TROUBLESHOOTING

Refer to the “Manual

oi

Selected (Jumper W2

Installed)” section below for problems that occur dur-

ing the “Startup and Checkout Procedure (Manual

oi

Test),” or during normal operation when manual

oi

operation is selected. Refer to the “Automatic

oi

Selected” section below for problems that occur dur-

ing normal operation when automatic

oi

operation is

selected.

IMPORTANT

To ensure reliable protection,

oi

related faults

should be corrected promptly. This is particularly

important in environments where oily substances

can accumulate on the detector window, poten-

tially blinding the detector.

MANUAL

oi

SELECTED (Jumper W2 Installed)

or Failure During Startup and Checkout Procedure

(Manual

oi

Test)

When manual

oi

is selected, the automatically initiat-

ed

oi

test is disabled. In normal operation with man-

ual

oi

selected, the sensor LEDs blink alternately at

five second intervals.

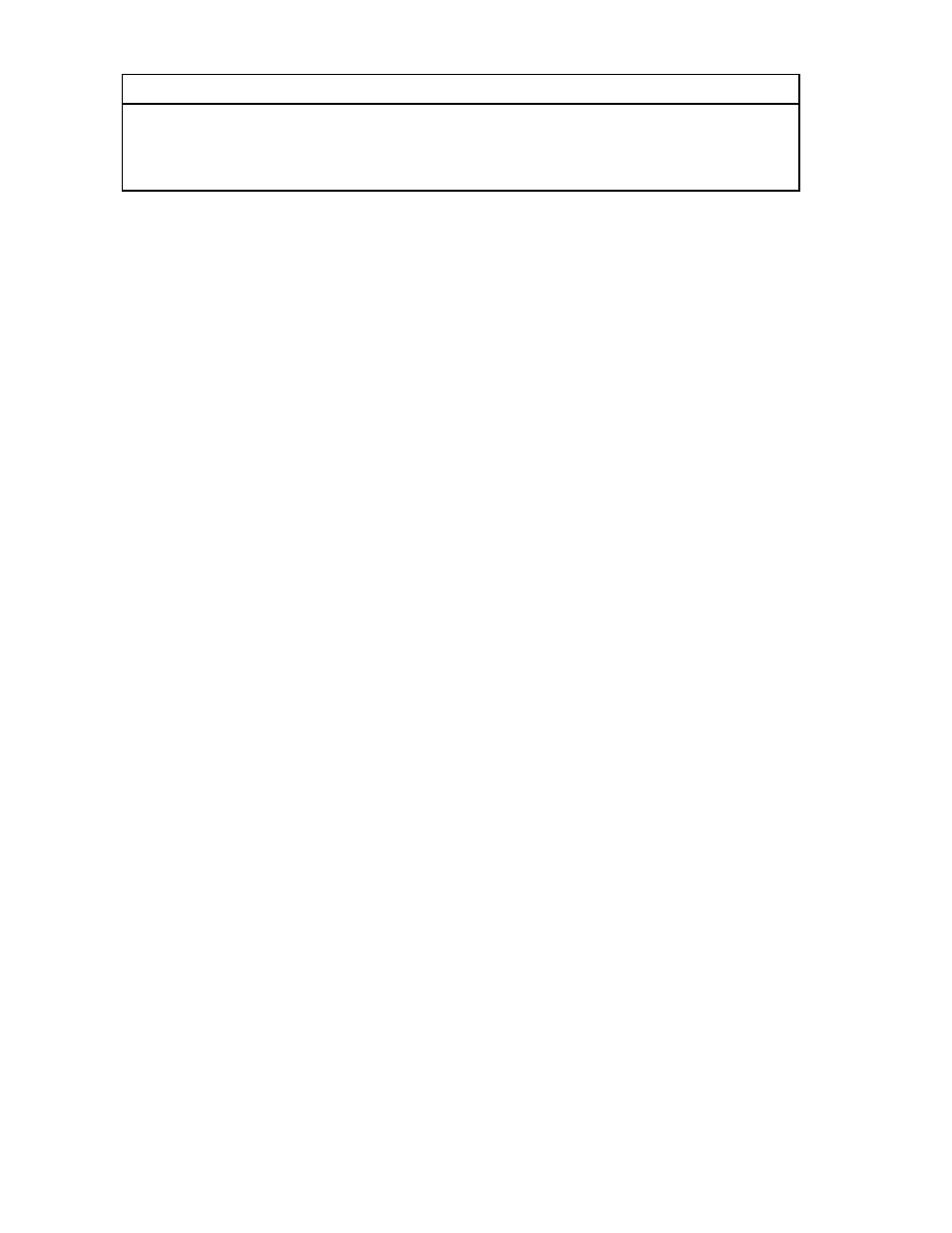

10

Table 5—Programmable Options

* Factory Setting

** U7652C with Auxiliary Relay Only

Pin Location

Function

Jumper Removed

Jumper Installed

W1

Latch/Non-Latch

Latching*

Non-Latching

W2

oi

Test

Automatic*

Manual

W3

Alarm Response

3 Second Response*

0.5 Second Response

W4**

Aux. Relay Operation

UV only*

UV or IR