Det-Tronics NTMOS IP66/IP67 H2S Gas Detector User Manual

Page 9

2.1

95-8670

7

IMPORTANT CALIBRATION NOTES

• Proper calibration requires the use of either

D et‑Tronics’ NTMOS calibration kit with

humidification tube and bottled H

2

S in air

(p/n 010272‑001), or the ampoule calibration

kit (p/n 007098‑005).

• When calibrating with bottled H

2

S in air, the

humidification tube

must be utilized, or inaccurate

readings will occur.

• WARNING: Using a gas mixture other than

50% span of H

2

S in air will produce inaccurate

calibration results, possibly resulting in a

dangerous condition if the detector under‑reports

the level of H

2

S.

Do not use bottled H

2

S with

nitrogen.

• Prevent all contact of any oil based material from

the humidification tube.

If background H

2

S gas is present, it may be necessary

to purge the detector with clean air to ensure that an

accurate zero or “clean air” condition is present prior to

initiating calibration.

CALIBRATION PROCEDURE

The NTMOS Detector requires zero and span

calibration, achievable with the NTMOS calibration kit

or the ampoule calibration kit. It is highly recommended

that the FlexVu UD10 Display Unit, GDTB Termination

Box, Model U9500B Transmitter, or Model R8471B

Controller be utilized with the NTMOS Detector to enable

non-intrusive field calibration. When using the UD10,

U9500B, or R8471B for calibration, refer to the related

manual for specific calibration instructions.

Calibrating a Stand-Alone NTMOS Detector

1. A dc current meter capable of measuring 4-20 mA

must be connected to the current loop output. This

can be accomplished by connecting a dc ammeter

in series with the load or by connecting a digital

dc voltmeter across a known load resistance and

calculating the current flow using the formula:

current (I) = voltage/load resistance.

2. If the detector is powered-up after a shutdown,

it must be allowed to warm-up for a period of 16

hours prior to calibration. (Before calibrating a new

detector, allow a 24 hour warm-up period after initial

power-up).

3. Initiate calibration by activating the calibration line.

4. The current output goes to 2.2 mA while the detector

automatically calibrates the zero output.

5. When the current output goes to 2.0 mA, apply 50%

span of H

2

S gas in air to the detector using the

humidification tube kit, or the ampoule calibration

kit. When using the humidification tube it must be

attached to the detector via a cal cup before applying

gas, and ensure that the flow rate is set to 0.5 liters/

min.

6. Upon successful calibration, the current output will

go to 1.8 mA. Remove the calibration gas. The

output will go to 4 mA. Reference Table 2 for the

calibration sequence.

NOTE

If the current output reads 1.6 mA, the calibration

has failed. Check the calibration gas expiration

date, verify that the calibration gas used is H

2

S

in air, or replace the detector and repeat the

calibration. Be certain that the humidification tube

is used during calibration.

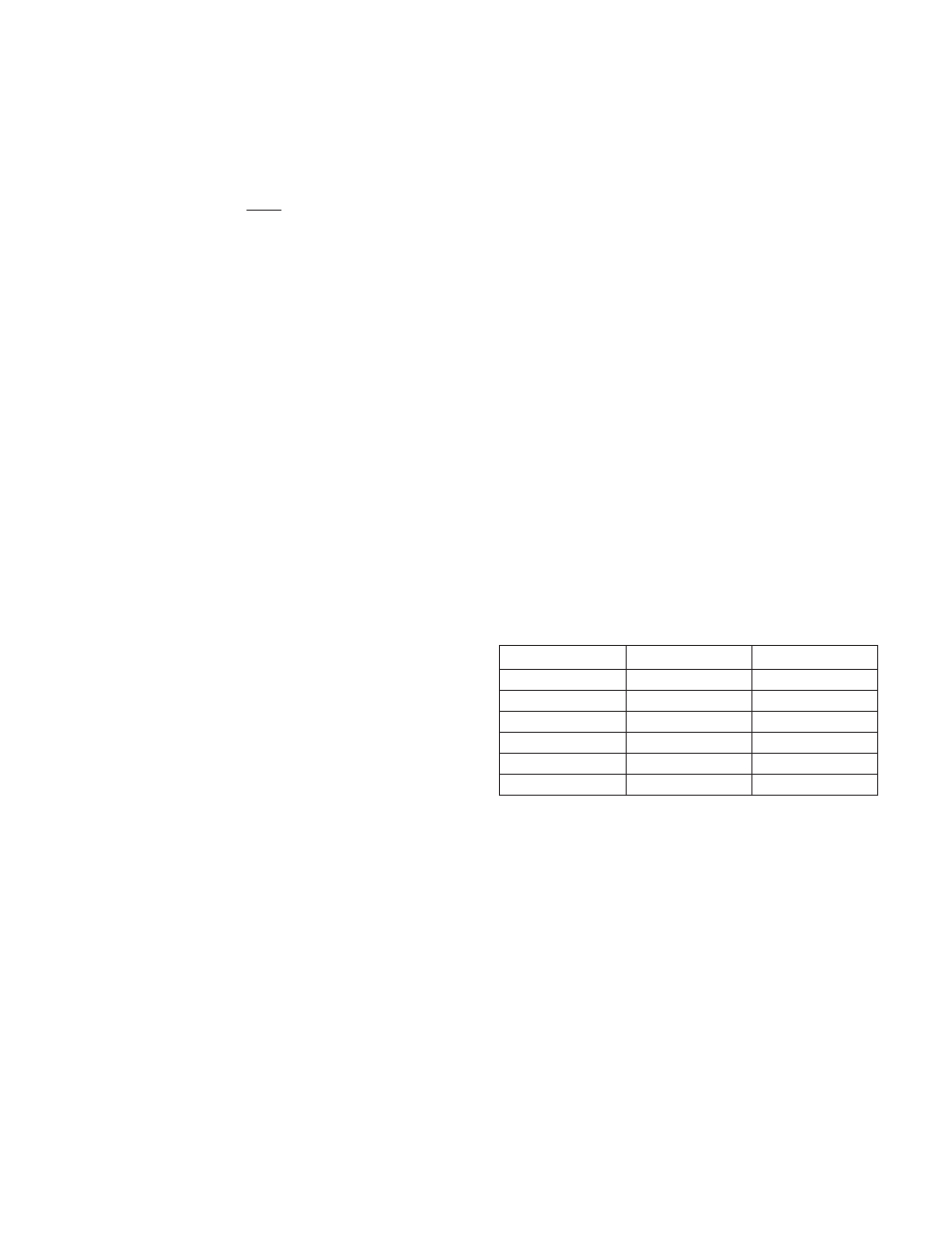

Current Output

Detector Action

Operator Action

Actuate Cal Line

2.2 mA

Zero Cal

None

1.6 mA

Cal Failed

Repeat Calibration

2.0 mA

Span Cal

Apply Cal gas

1.8 mA

Cal Complete

Remove Gas

4.0 mA

Normal Operation

Table 2—NTMOS Detector Calibration Sequence