Startup procedure, Calibration – Det-Tronics NTMOS IP66/IP67 H2S Gas Detector User Manual

Page 8

95-8670

2.1

6

STARTUP PROCEDURE

WARNING

Ensure that any output loads actuated by

the detection system are bypassed to prevent

accidental or unnecessary activation of these

devices.

1. Apply power to the system.

2. Remove the (red) protective cap and desiccant bag

from the detector.

NOTE

Transmitters and display/control devices

typically have a “warm‑up” period to allow the

detector to stabilize before beginning normal

operation (the NTMOS Detector can remain

in warm‑up for up to 30 minutes). After long

periods without power, the detector output may

still not have returned to zero ppm by the end

of the warm‑up period. In some cases, an alarm

level of H

2

S may be indicated. Keep all output

loads that are actuated by the system in bypass

until all alarms clear.

3. Allow the detector to operate for 16 to 24 hours

prior to an initial calibration

, then perform the

“Calibration Procedure" as described in the following

section. It may be necessary to refer to other

transmitter and/or controller manuals to complete

calibration.

4. Complete any additional startup/commissioning

requirements as described in the manual provided

with the transmitter/control device.

5. Place the system in normal operation.

CALIBRATION

FREQUENCY OF CALIBRATION

The calibration frequency required in different

applications can vary depending upon the amount of

background gas, concentration of H

2

S, and ambient

environmental conditions.

Calibration must be performed:

— When a new system is initially put into service.

— When the detector is replaced.

— If a transmitter, controller or other device used in

conjunction with the NTMOS Detector is replaced.

The following calibration/bump test schedule is

recommended to ensure reliable operation in most

applications:

1. 24 hours after initial power-up (initial calibration)

2. 30 days after initial calibration

3. 60 days after initial calibration

4. 90 days after initial calibration

If all recommended calibration/bump tests are within

the acceptable limits, the tests can be performed

at (maximum) 90-day intervals thereafter. If large

adjustments occur (greater than 10%), calibration

intervals should be reduced.

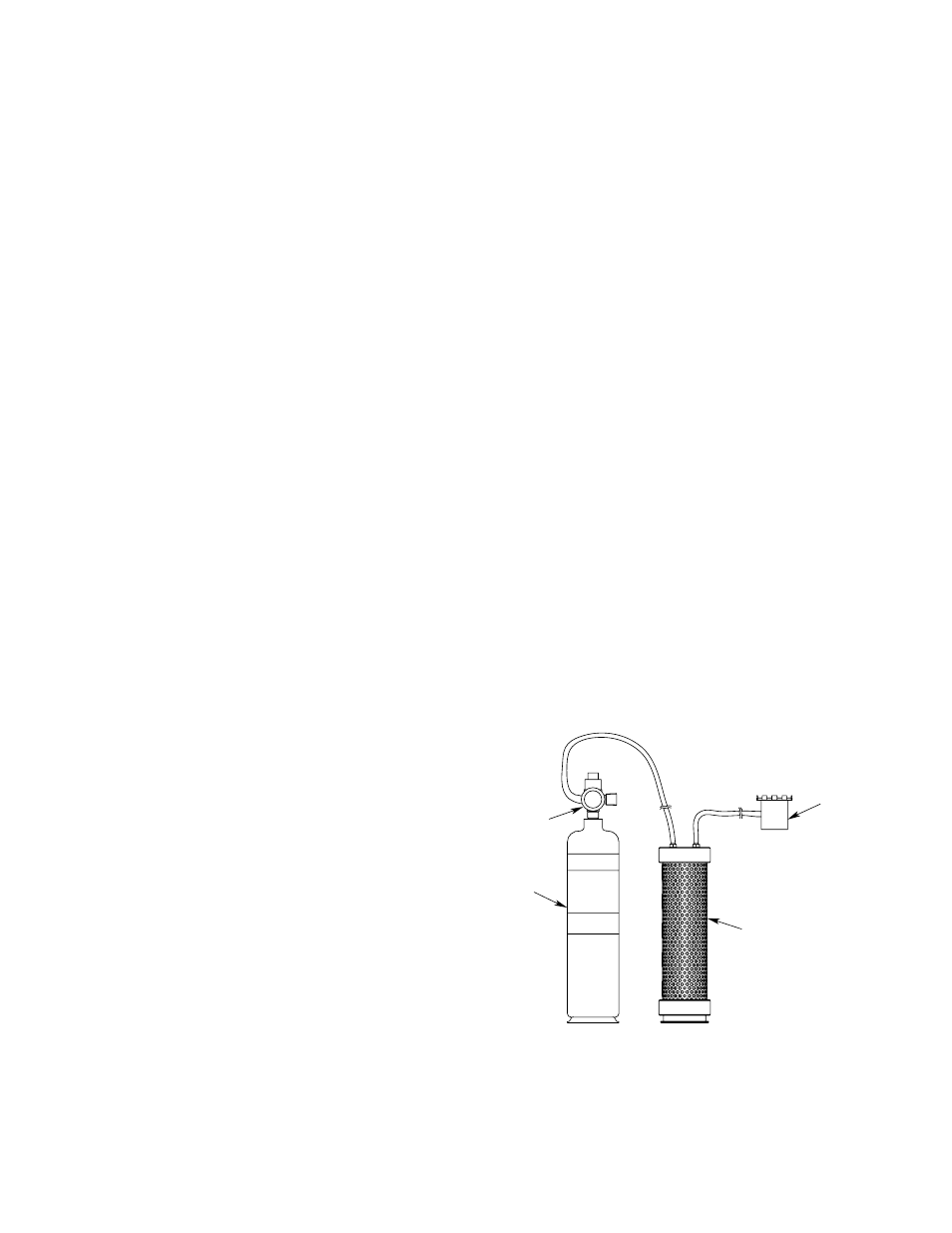

CALIBRATION GAS

The NTMOS H

2

S detector must be calibrated using the

humidification tube with bottled H

2

S in air (Figure 7), or

with the ampoule calibration kit.

HUMIDIFICATION TUBE KIT

(Includes cage and tubes)

A2503

CAL CUP

REGULATOR

BOTTLED H

2

S

GAS IN AIR

Figure 7—Humidification Tube Assembly