Det-Tronics NTMOS IP66/IP67 H2S Gas Detector User Manual

Page 5

2.1

95-8670

3

DETECTOR POSITIONING

Proper detector location is essential for providing

maximum protection. The most effective number

and placement of detectors varies depending on the

conditions at the job site. The individual designing

the installation must rely on experience and common

sense to determine the number of detectors needed

and the best locations to adequately protect the area.

The following factors are important and should be

considered for every installation:

1. Since hydrogen sulfide is a highly toxic gas, a

primary consideration in determining optimum

detector locations is to identify where the most

likely release point of the hazard is located. Use

local or recommended practices to identify these

locations.

2. Factors such as vapor density should also be

considered when determining detector locations.

Hydrogen sulfide is slightly heavier than clean air,

and therefore may tend to settle near the floor or

ground, unless it is heated, mixed with other gases

that are lighter than air, or prevented from doing so

by ambient air movement patterns.

3. How rapidly will the H

2

S gas diffuse into the air?

Select a location for the detector as close as practical

to an anticipated leak source. As gas disperses it

becomes difficult to detect as it is diluted.

4. Detectors should be placed where the most

concentrated accumulation of hydrogen sulfide gas

is anticipated. Also consider the fact that some

ventilation systems do not operate continuously,

and therefore areas with poor circulation should be

evaluated for toxic gas accumulation.

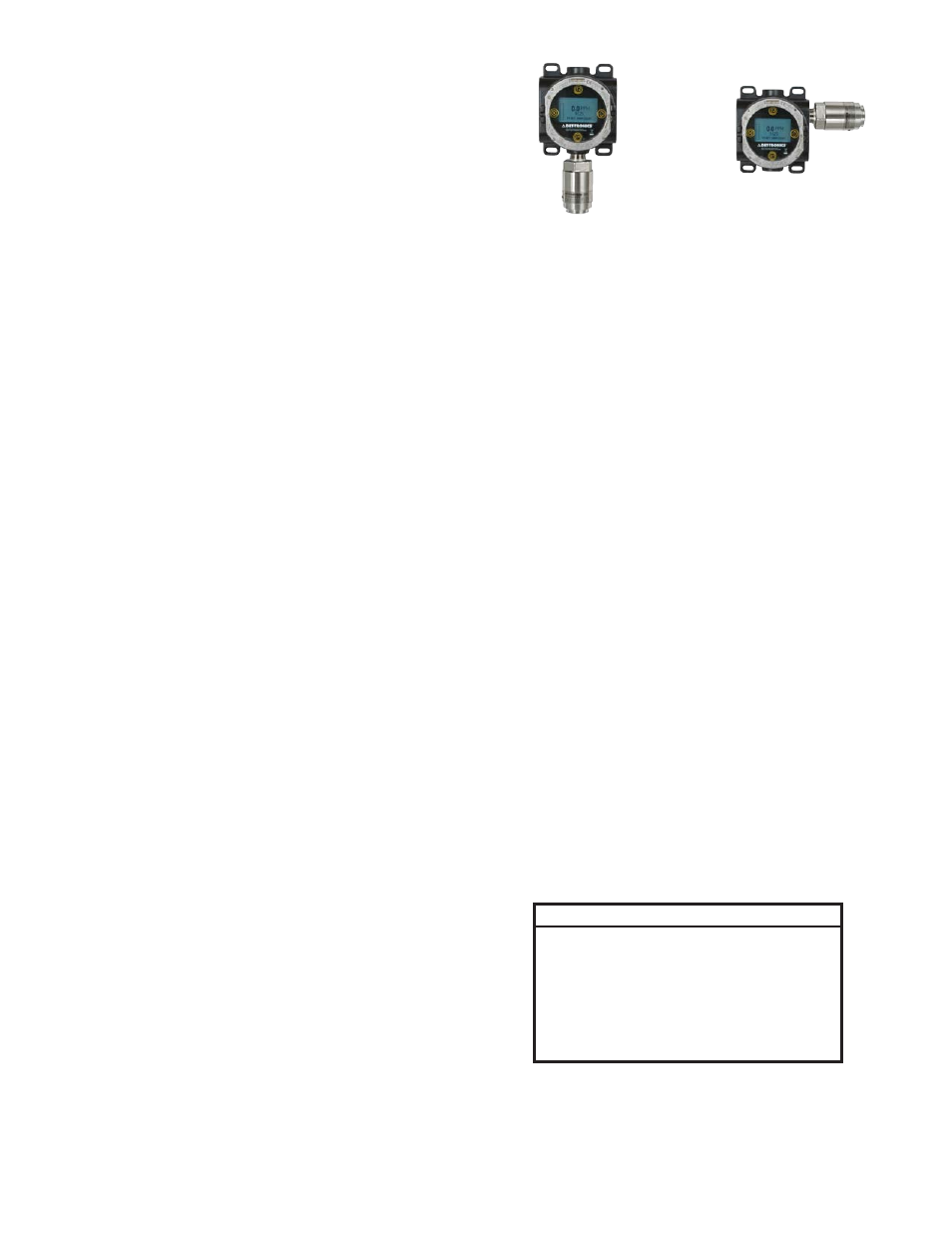

5. The detector must always be installed pointing

straight down (see Figure 1).

6. The detector must be accessible for testing and

calibration. Allow adequate space for attaching

the NTMOS approved H

2

S calibration device.

See Specifications section of this manual for

dimensions.

7. Exposure to excessive heat or vibration can cause

premature failure of electronic devices, and should

be avoided if possible. Shielding the device from

intense sunlight will reduce solar heating. For details

regarding the operating and storage temperatures of

the NTMOS Detector, refer to “Temperature Range”

in the Specifications section.

WIRING REQUIREMENTS

The maximum allowable distance between the NTMOS

Detector and transmitter/control device is limited by the

resistance of the cabling used. To ensure proper operation,

a minimum of 18 Vdc is required at the detector.

When mounted remotely from the transmitter/controller,

shielded cable or dedicated conduit is required for wiring

the detector. Ground the shield at the transmitter/controller

end only.

In applications where the detector cable is installed

in conduit, the conduit should not be used for wiring to

other electrical equipment whenever possible. If other

equipment power wiring is run in the same conduit, the

detector cabling must be shielded.

If an additional signal conditioning or relay output

transmitter is being used along with the NTMOS Detector,

refer to the specific transmitter manual for detailed wiring

instructions.

It is important that moisture not be allowed to come in

contact with the electrical connections of the system.

Use proper piping techniques, breathers, glands, and

seals as required to prevent water ingress and/or maintain

explosion-proof ratings.

* If the yellow wire is not being used, do not connect it to dc minus .

** For factory use only . Connect to isolated Spare terminal or

tape off to prevent contact to any conductor .

Wire Color

Function

Red

24 Vdc +

Black

24 Vdc –

White

4-20 mA Signal

Yellow*

Calibrate Line

Orange**

Connect to Isolated Spare

Grey**

Connect to Isolated Spare

Table 1—NTMOS Detector Wiring Identification

Figure 1—Recommended Orientation of NTMOS Detector (with UD10)

CORRECT

INCORRECT