B-scan – Dakota Ultrasonics MMX-7 User Manual

Page 48

Dakota Ultrasonics

44

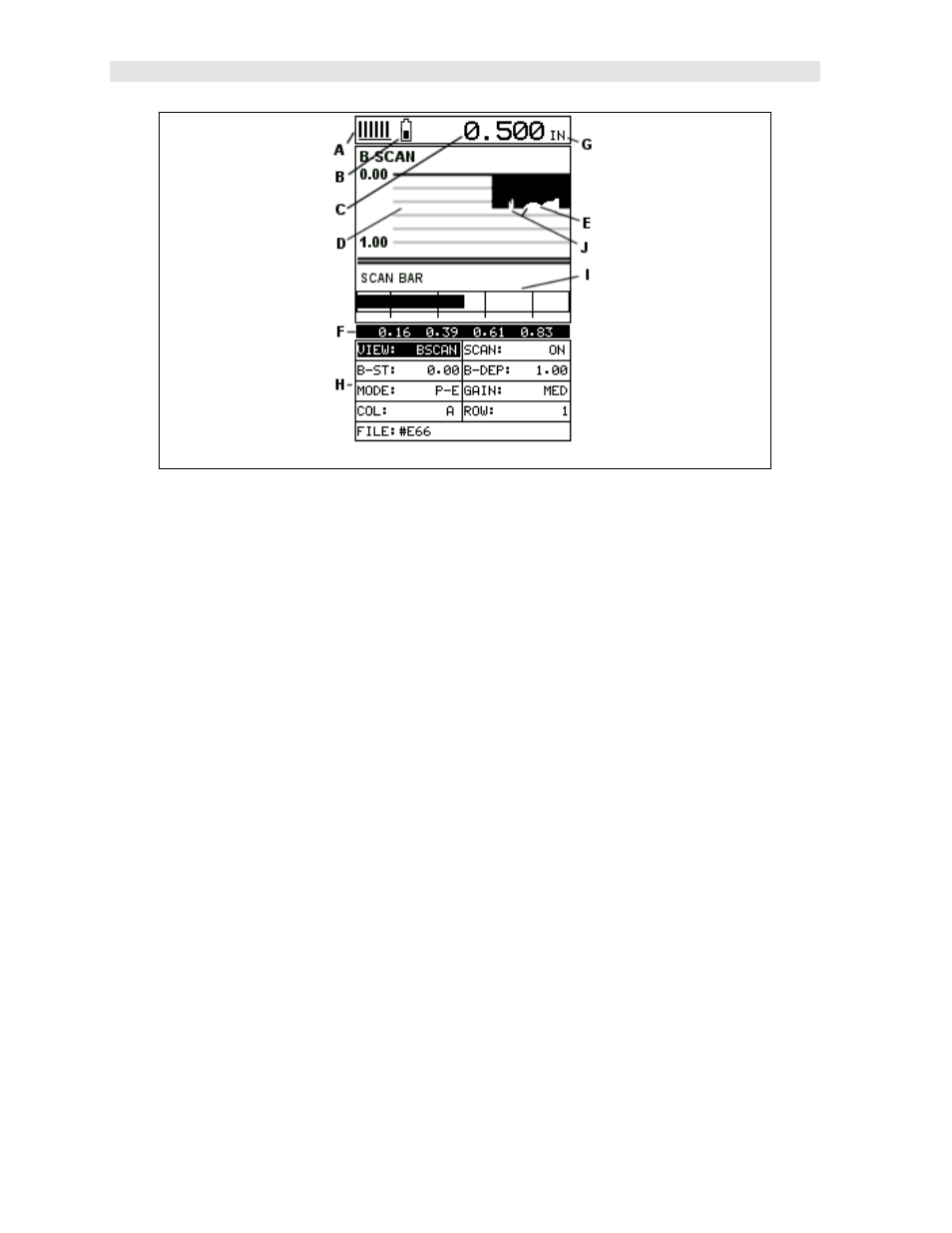

B-Scan View

B-Scan

The B-Scan displays a time based cross section view of test material. This view is

commonly used to display the contour of the blind, or underside, surface of a pipe or

tank application. It is very similar to a fish finder. If a flaw or pit is located during a

scan, the B-Scan will draw the pit on the screen. The solid black rectangle in the

diagram at location E represents the cross section, or side view of the material. You

will notice that the overall thickness of the material is .500”, and the display range is

0.00” to 1.00” respectively. The B-Scan view draws at a rate of 15 seconds per

screen from right to left. Also notice at location J, the pits and corroded bottom

surface of the material.

It’s important to note that the measurement range on the display be set wide enough,

so that the maximum thickness of the material can be viewed on the display. Using

the diagram above, if the material thickness was actually 1.75”, the underside of the

material would not be viewable according to the current range at 0.00” – 1.00”. All

the user would see is a black screen from 0.00” – 1.00” with no view of the bottom

contour at 1.75”.

The following is a list of the viewable features on the display:

A) Stability of Reading Indicator – Indicates the stability of the echo signal on a

scale of 1 to 6 – the solid bars displayed in the figure above indicate a repeatable

signal. If the MMX-7 is displaying a reading from memory, the repeatability

indicator will be replaced by the text “MEM”.

B) Battery life indicator – Fully charged batteries will appear filled in solid. Note:

The diagram shows the batteries at approximately 50%.

C) Thickness reading – Digital readout of thickness (inches or millimeters).