Prepare site • prepare burner • mount burner, Model ezgas pro gas burner — instruction manual, Figure 5 flame rod/ ignitor electrode assembly – Carlin EZGasPro User Manual

Page 8: Figure 4 flame rod and ignitor placement, Bsize, Figure a figure b, Carlin combustion technology, inc

Model EZGas Pro gas burner — Instruction manual

Carlin part number MNEZGas Rev. 10/28/13

– 8 –

Where appliance instructions differ from this manual, follow the appliance instructions.

1. Prepare site • prepare burner • mount burner

(continued)

Inspect/redrill gas orifice when required

• Turn off power to the burner/appliance before proceeding.

• Close main manual gas valve in gas line to burner. Then disconnect

the ground joint union to allow rotating burner combination gas valve.

You must disconnect power to burner and close main

manual gas valve before proceeding. Failure to do so

could result in severe personal injury, death or substantial

property damage.

• Unplug wire harness from combination gas valve.

• Remove the combination gas valve (item 20, page 3) and the orifice

nipple (item 6, page 3). Remove the orifice nipple from the gas valve.

• Read the correct orifice drill size from Table 1, page 7. Then check

actual orifice size using that size twist drill bit.

•

If gas orifice is smaller than required, redrill the orifice to the cor-

rect size, if necessary.

•

If gas orifice is larger than required, obtain a replacement orifice

nipple from Carlin. If necessary, drill the orifice hole in the replace-

ment orifice nipple to the correct size.

Drill the orifice carefully, avoiding drill wobble. Wobble will

cause the orifice to be over-sized. The orifice nipple should

be secured in a vise, if possible, to ensure it is steady dur-

ing the drilling process.

• Write the orifice size on the orifice nipple label (or on the French

label attached to the burner for Canadian installations).

• Replace the gas valve and piping, using only pipe dope listed for use

with liquefied petroleum gases. Make sure the arrow on the orifice

nipple label points in the direction of gas flow.

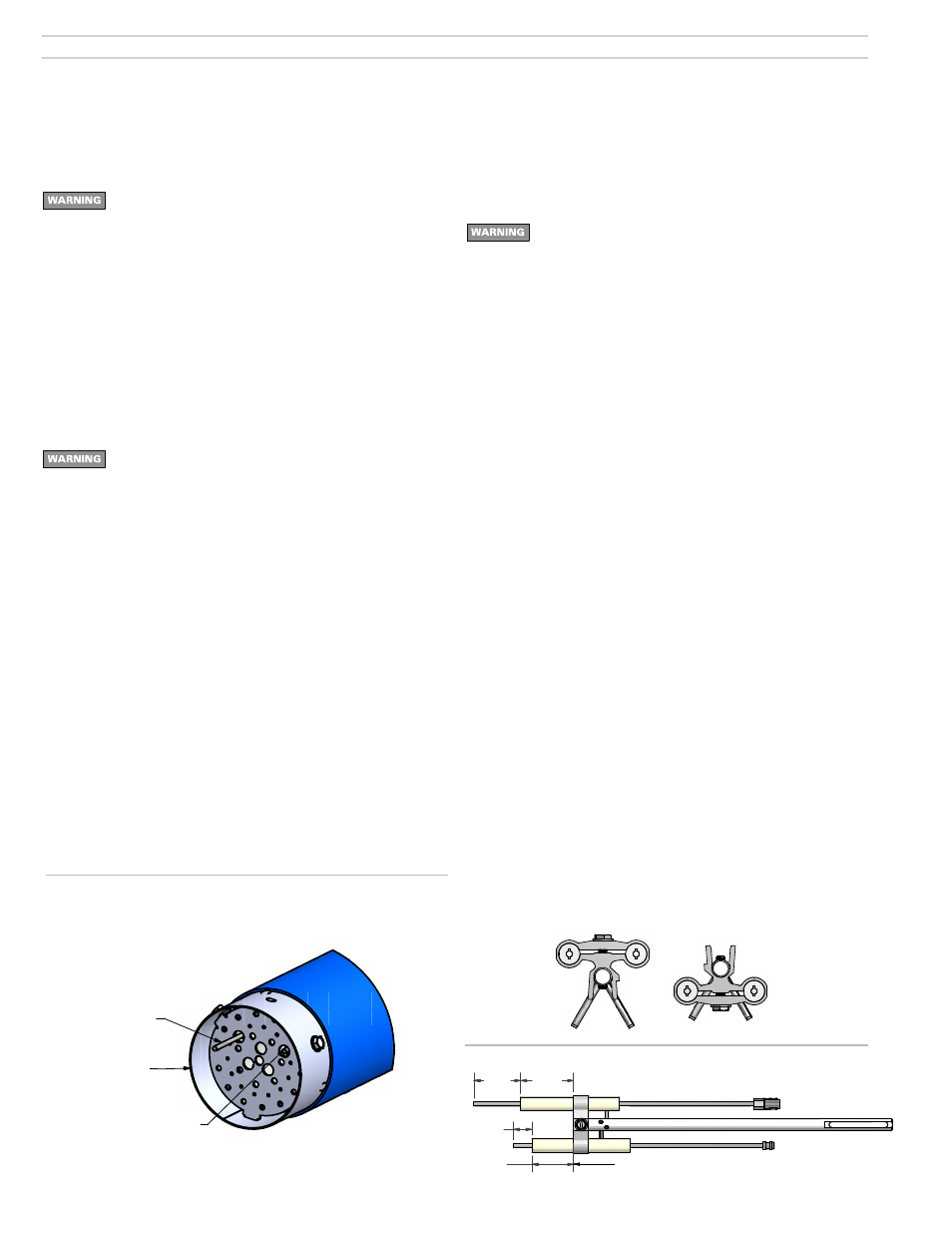

Flame rod and ignitor electrode

• Inspect the burner from air tube end. Flame rod should extend

through the diffuser plate as shown in Figure 4. Ignitor electrode

should be flush with inner face of diffuser plate as shown.

• The flame rod and ignitor electrode must not touch the diffuser or any

grounded metal surface at any point. The flame rod and electrode

should be as close as possible to the centers of the diffuser holes. If

either the flame rod or electrode is closer than 1/16” to the diffuser,

remove assembly (see page 15 for removal instructions and verify

dimensions per Figure 5). Bend the end of the flame rod or ignitor

electrode as required. Replace assembly and check spacing again.

Continue adjusting as necessary until neither rod nor electrode is

closer than 1/16” to the diffuser.

Figure 5 Flame rod/ ignitor electrode assembly

Install gas valve on burner

1. Read WARNING’s on page 9 before installing gas valve.

2. Apply a small amount of pipe dope (suitable for propane gas) to gas

valve outlet connection, gas line nipple and burner gas connection.

Assemble pipe nipple to gas valve. Install gas line nipple in burner

gas connection.

To avoid damage to gas valve, do not hold valve with a

pipe wrench or over-tighten. Use only a crescent wrench

or other means. Failure to comply could result in severe

personal injury, death or substantial property damage.

3. Connect wire harness to valve.

Inspect components and wiring

• Visually inspect all burner components and wiring.

• Verify that wiring is intact and connectors are securely connected.

• Verify that all burner components are in good condition.

Mount burner in appliance

• Verify appliance burner front plate dimensions per page 19.

• Slide gasket supplied with burner over end of air tube.

• Insert burner into appliance opening and bolt in place.

Verify and install diffuser plate

Each plate will be stamped on the face of the diffuser with a letter desig-

nating the diffuser type (Example A, B, C, 9S).

1. Install the diffuser on the air tube by placing the wide tab into the slot

at the end of the air tube with the 90

o

bent tabs of the diffuser plate facing

into the air tube.

2. Fasten diffuser plate to the air tube with the two screws provided.

3. Make sure the flame rod and electrode are not touching the diffuser

plate.

4. If flame rod or electrode is making contact with the diffuser plate the

burner will not prove flame and will enter a lockout condition.

Air tube orientation for right side (motor side) gas supply (Burners

with Adjustable Flange only)

1. The air tube may be rotated from the left side gas inlet to the right side

gas inlet (motor side).

2. Remove the electrode/flame rod assembly as described in the Mainte-

nance section. It should look like Figure A.

3. Remove the four 5/16 screws that hold the air tube to the burner chas-

sis. Now the air tube can be rotated 180

o

so the gas inlet is on the right

side (motor side). Reinstall the four 5/16 screws, securing the tube back

onto the chassis.

4. Remove the screw holding the electrode/flame rod bracket to the alu-

minum rod. Reassemble the electrode/flame rod bracket to the aluminum

rod as shown in Figure B while positioning the flame rod and electrode as

shown in Figure 5.

5. Replace the electrode/flame rod assembly as described in the Main-

tenance section. Note that the aluminum rod must now sit on top of the

nylon washer.

Figure 4 Flame rod and Ignitor placement

QUALITY CHARACTERISTICS

CRITICAL

MAJOR

A

MAJOR

B

MINOR

NO

SYMBOL

CRITICAL

STATISTICAL

SEE QAS 1000 FOR VENDORS QUALITY

ASSURANCE REQUIREMENTS

TOLERANCE UNLESS OTHERWISE SHOWN

FRACTIONAL `1/64 ANGLE `1/2~

DEC. .XX `.01 .XXX `.005

THIS DOCUMENT MAY NOT BE

REPRODUCED WITHOUT WRITTEN

PERMISSION FROM CARLIN

COMBUSTION TECHNOLOGY, INC.

REMOVE BURR AND FLASH FOR

PROPER OPERATION AND GOOD

APPEARANCE

THIRD ANGLE PROJECTION

DO NOT SCALE DRAWING

INTERPRET ALL DIMENSIONS

PER ANSI Y14.5 1994

CARLIN COMBUSTION TECHNOLOGY, INC.

EAST LONGMEADOW, MA U.S.A.

PART

NUMBER

MAT'L

NUMBER

PART

DESC.

MAT'L

DESC.

ITEM

CLASS

ITEM

CLASS

ECN #

REV SH

OF

DRAWING

NUMBER

DRAWN

DATE

SCALE

58572

wmisiaszek

9/4/2013

ECN

BSIZE

ALL LINEAR DIMENSIONS

ARE IN INCHES

REVISION HISTORY

REV

DESCRIPTION

ECN

BY

DATE

.

Released to Production

ECN

MPC

5/4/2009

Ignitor electrode

Electrode bracket

Flame rod

Support rod

1.55"

1 3/4"

0.61"

1 3/8"

Flame rod

Ignitor electrode

Support rod flush at both ends

QUALITY CHARACTERISTICS

CRITICAL

MAJOR

A

MAJOR

B

MINOR

NO

SYMBOL

CRITICAL

STATISTICAL

SEE QAS 1000 FOR VENDORS QUALITY

ASSURANCE REQUIREMENTS

TOLERANCE UNLESS OTHERWISE SHOWN

FRACTIONAL

`

1/64 ANGLE

`

1/2

~

DEC. .XX `

.01 .XXX

`

.005

THIS DOCUMENT MAY NOT BE

REPRODUCED WITHOUT WRITTEN

PERMISSION FROM CARLIN

COMBUSTION TECHNOLOGY, INC.

REMOVE BURR AND FLASH FOR

PROPER OPERATION AND GOOD

APPEARANCE

THIRD ANGLE PROJECTION

DO NOT SCALE DRAWING

INTERPRET ALL DIMENSIONS

PER ANSI Y14.5 1994

CARLIN COMBUSTION TECHNOLOGY, INC.

EAST LONGMEADOW, MA U.S.A.

PART

NUMBER

MAT'L

NUMBER

PART

DESC.

MAT'L

DESC.

ITEM

CLASS

ITEM

CLASS

ECN #

REV SH

OF

DRAWING

NUMBER

DRAWN

DATE

SCALE

wmisiaszek

9/4/2013

ALL LINEAR DIMENSIONS ARE IN INCHES

REVISION HISTORY

REV

DESCRIPTION

ECN

BY

DATE

.

Released to Production

W.M.

04-06-10

Flame rod

End of air tube

Ignitor electrode

*Tip should extend in front of diffuser by 1 1/4”.

(Tip should be flush with inside surface of diffuser).

*

QUALITY CHARACTERISTICS

CRITICAL

MAJOR

A

MAJOR

B

MINOR

NO

SYMBOL

CRITICAL

STATISTICAL

SEE QAS 1000 FOR VENDORS QUALITY

ASSURANCE REQUIREMENTS

TOLERANCE UNLESS OTHERWISE SHOWN

FRACTIONAL

`

1/64 ANGLE

`

1/2

~

DEC. .XX `

.01 .XXX

`

.005

THIS DOCUMENT MAY NOT BE

REPRODUCED WITHOUT WRITTEN

PERMISSION FROM CARLIN

COMBUSTION TECHNOLOGY, INC.

REMOVE BURR AND FLASH FOR

PROPER OPERATION AND GOOD

APPEARANCE

THIRD ANGLE PROJECTION

DO NOT SCALE DRAWING

INTERPRET ALL DIMENSIONS

PER ANSI Y14.5 1994

CARLIN COMBUSTION TECHNOLOGY, INC.

EAST LONGMEADOW, MA U.S.A.

PART

NUMBER

MAT'L

NUMBER

PART

DESC.

MAT'L

DESC.

ITEM

CLASS

ITEM

CLASS

ECN #

REV SH

OF

DRAWING

NUMBER

DRAWN

DATE

SCALE

EZ

GAS_RevA_FlippedElectrode_Dims

wmisiaszek

9/4/2013

ECN

BSIZE

ALL LINEAR DIMENSIONS

ARE IN INCHES

REVISION HISTORY

REV

DESCRIPTION

ECN

BY

DATE

.

Released to Production

ECN

MPC

5/4/2009

3 1/2"

7 3/8"

Air tube length

(as needed for apliance)

5 7/8"

9 1/4"

11 3/4"

6 3/4"

10 3/4"

UTL

6

1

2

3

4

7

5

8

Figure A

Figure B