Wire burner, Verify power supply, Checking burner flame signal – Carlin EZGasPro User Manual

Page 10: Code compliance, General wiring requirements, Model ezgas pro gas burner — instruction manual

Model EZGas Pro gas burner — Instruction manual

Carlin part number MNEZGas Rev. 10/28/13

– 10 –

Where appliance instructions differ from this manual, follow the appliance instructions.

3. Wire burner

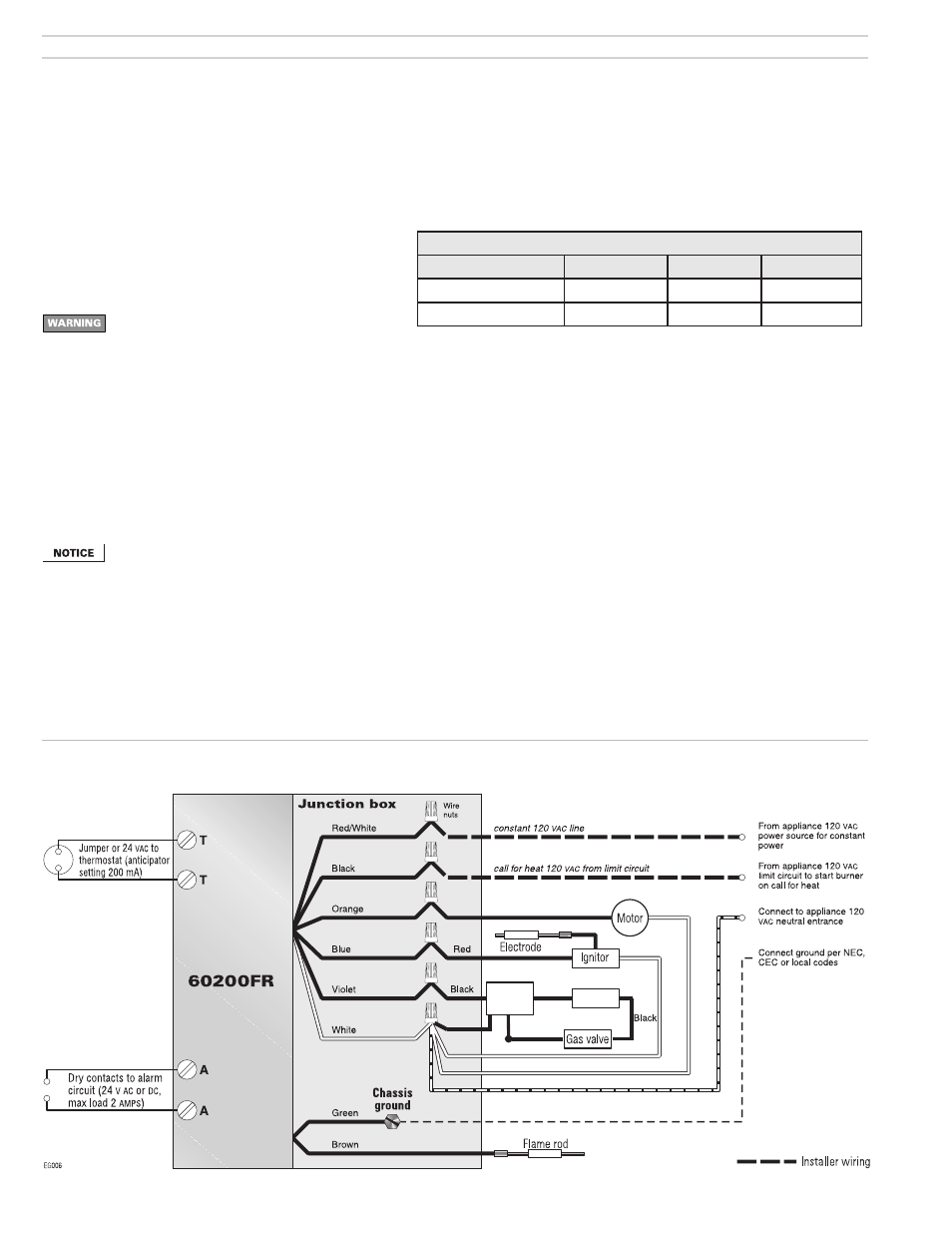

Figure 7 Wiring diagram — EZGas Pro burner with 60200FR primary control — typical wiring to appliance

Verify power supply

1. The burner requires a 120

vac

/60

hz

/single-phase power supply, with at least a 5-amp

fuse. The current draw will be (when equipped with Carlin motor and Carlin 41800

electronic ignitor):

2. The 120

vac

power connections to the black and red/white wires of the 60200FR

must be the same polarity

from the same power source. DO NOT attempt to supply

separate power sources. Check the power from the heat exchanger with a voltmeter.

Verify that the supply to the black and red/white wires are from the 120

vac

HOT side

and that the power is no less than 102

vac

nor more than 132

vac

.

Checking burner flame signal

The 60200FR uses flame rectification to detect the flame. Because the grounded

metal surface area near the flame rod is much larger than the surface of the flame

rod, current flows through the flame more easily in one direction than the other. This

causes an AC voltage applied to the flame rod to result in a DC current. (Note that, if

the flame rod should touch a grounded metal part, the current would be AC, not DC,

and the control would not sense flame and go into a lockout condition).

The 60200FR control has a 3 mm flame signal test jack (item 13, page 3) that can

be used with a flame signal meter, such as the Honeywell W136. Or you can use a

standard 3 mm stereo plug fitted with two leads. Connect these leads in series with

your ammeter leads to read DC microamps.

The minimum flame signal needed to satisfy the 60200FR sensing circuit is

0.8 microamps. The control will register flame failure at any lower signal.

Code compliance

The burner/appliance installation must comply with

codes listed on page 2 and any other locally appli-

cable codes.

General wiring requirements

Read and follow the guidelines below. Failure to comply

could result in severe personal injury, death or substantial

property damage.

Electrical shock hazard — Disconnect electrical supply

to the burner before attempting to service.

Electrically ground burner — The burner must be

grounded in accordance with local codes or, in the ab-

sence of local codes, with the National Electrical Code,

ANSI/NFPA 70 (in Canada, per Canadian Electrical Code,

CSA C22.1/CSA C22.2).

Label all wires before removing for servicing. Wiring

errors could result in unsafe appliance/burner operation.

Read appliance manufacturer’s instructions completely

before wiring burner.

The 60200FR control requires a constant 120

vac

power

source from the appliance as well as power from the

appliance limit circuit. See Figure 7.

Check polarity

carefully. If hot and neutral wires are reversed at

appliance power source, the control will lockout on

flame failure.

If replacing any of the wire supplied with the burner, use

minimum #18 AWG 125°C or better.

Air flow

switch

Yellow

24VAC

Transformer

Yellow

White

White

Approximate amp draw of EZGas Pro burners

Motor-->

1/15 HP

1/7 HP

1/6 HP

During ignition

2.5 AMPS

2.8 AMPS

3.0 AMPS

Steady operation

2.0 AMPS

2.3 AMPS

2.5 AMPS