C.B.S. Scientific DCX-700 User Manual

Page 12

12

Dual Cool DCX-700 Instructions 9-30-13

4.1

Alternate Protocol: Using Gel Wrap™ Gasket Casting Method

(Not using Pre-cast gels)

1. Place all components in an authorized work area. You will need: glass plate set,

Gel Wrap™ Gasket, spacer set, comb, 3 GPC-0002 clamps, and polyacrylamide

solution. Prepare and clean glass plates by hand washing both plates with a high

quality lab detergent followed by a complete rinsing with dH

2

O. Air-dry or use a

lint-free tissue. Spray/wipe the chosen inner surfaces of the plate set with 95%

ethanol and dry with lint-free tissue.

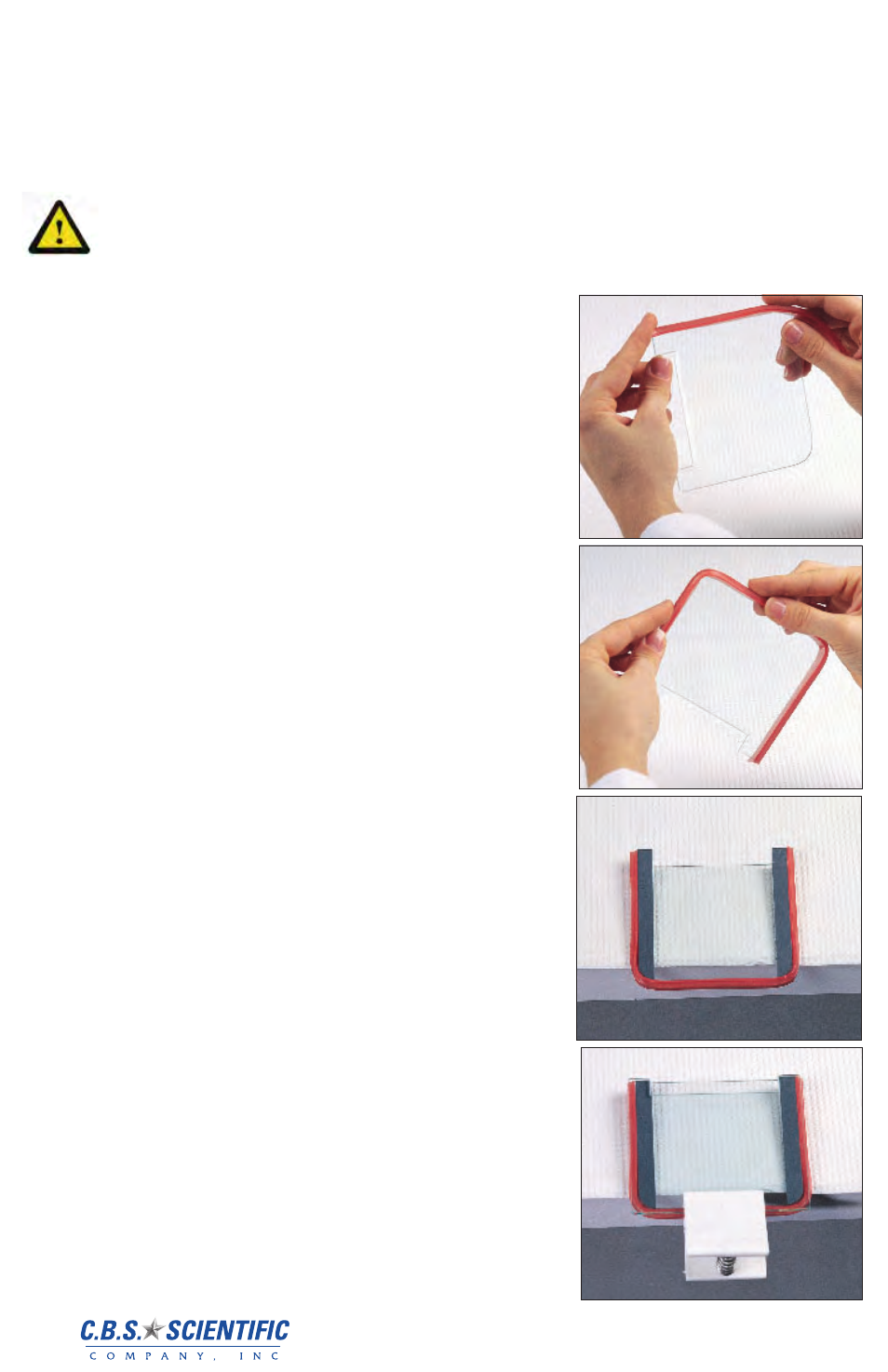

2. Start gel casting procedure by holding the 3mm

thick, notched back plate with the rounded

bottom corners and applying the gasket around

one side of the glass plate. Note: one side of

the “U” shaped gasket is flat, and the other

side has tubing that will act as a seal around

the spacers.

3.

When applying the gasket over the rounded

corners of the notched glass plate, make sure

the cuts on the gasket align with the rounded

corners of the glass plate. Once the gasket

is pushed over the bottom edge and corners,

work it down the remaining side.

4. Place the gasketed plate on the lab bench with

the tubing side up, and extend the bottom of

the plate over the edge of the bench, approxi-

mately ¾ of an inch. Place the spacers along

side the inside edges of the gasket. Be sure

the rounded corner end of each spacer is fac-

ing the outside bottom of the plate, following

the radius of the glass.

5. Place the thinner unnotched back plate on

top of the bottom assembly, starting from the

bottom edge and gently easing the plate down.

Verify the gasket is smooth around the edges

and then

clamp along the bottom.

6. Lift the assembly and stand it on the base of the

clamp. For leveling, push glass plate assembly

down until it stops against clamp body. Clamp

the sides of the assembly with additional casting

clamps on either side. As each clamp is at-

tached, be sure the gasket is aligned between the

plates forming a seal.

7. Apply PAGE solution to gel plate sandwich using

a syringe or pipette. If using a stacking gel, pour

desired height of running gel, then overlay a small

amount of dH

2

O or 0.1% SDS solution to top of

gel.

8. After polymerization, rinse with buffer, add stack-

ing gel solution and insert comb. For regular, unit

percentage gels, add polyacrylamide solution to

correct height, and insert comb. Allow gel to set,

usually 20 minutes. Extra gel solution in pipette

or syringe can be monitored to test polymeriza-

tion of gel mix.

9.

Disassembly (see right and below right). Hold the

clamped plate assembly with one hand. Remove

the gasket by starting at one of the top ends and

pulling up and out on the gasket until it releases

from the plate, up to the bottom of each of the

white clamps. When each clamp is reached DO

NOT remove it, instead feed the gasket down

through the clamp body and repeat pulling up and

out. Continue feeding until the gasket is fully de-

tached. Once gasket is removed, detach clamps.

If gel, is not to be used immediately, wrap entire

plate sandwich with plastic wrap tightly to seal

and store at 4°C for up to a month.