Auto Meter 8592 User Manual

Diesel exhaust pressure gauges, Installation, Exhaust particle trap recommendation wiring

INSTALLATION INSTRUCTIONS

DIESEL EXHAUST PRESSURE GAUGES

2650-1700-00

CAUTION!

As a safety precaution, the

+12V terminal of this product

should be fused before

connecting to the 12V ignition

switch. We recommend using a

3 Amp, automotive type fuse.

NOTE: When the ignition

is off the pointer

may not always

rest at zero.

QUESTIONS

:

If after completely reading these instructions you have questions regarding the operation or installation of your instrument(s),

please contact Auto Meter Technical Service at

866-248-6357.

You may also email us at

Additional information can also be found at

http://www.autometer.com

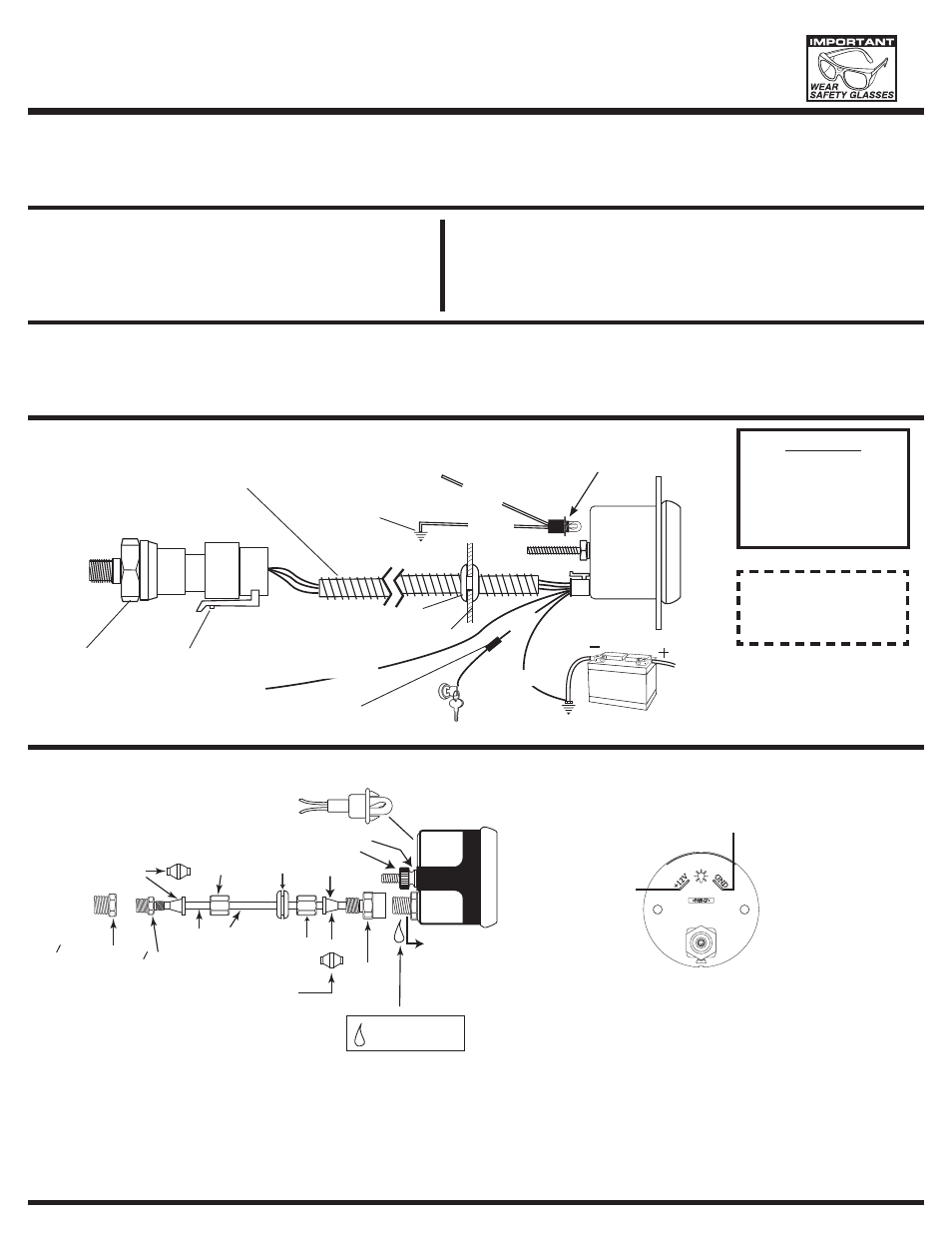

Installation

1. The 2

1

⁄

16

" gauges may be mounted in a 2

1

⁄

16

" diameter hole. The

hole may be either a hole in the dash, a gauge panel or an Auto

Meter Gauge Pod. (It is best to connect all wiring to the gauge

before mounting it into the gauge hole.)

2. Follow the diagram below to connect 12 volt lighting.

The pointer will move backward to the stop pin and then move to

the zero box. This procedure is an auto-calibration function and is

performed on every power-up. While this test is being performed,

the gauge may make a clicking sound. This is normal.

Exhaust Particle Trap Recommendation

Wiring

To extend the maintenance period on the copper coil, Auto Meter recommends the installation of the Diesel Particle Trap kit, model #5375. The Diesel Particle

is inserted between the copper tubing and either the FSE pressure sensor or the nylon tubing used on the mechanical gauge. The trap provides an expansion

chamber for the soot particles to collect, similar to a dust collector. It also incorporates a z brass snubber to minimized pressure spikes at the pressure sensor or

mechanical gauge. It is easy to open for removing accumulated soot.

SENDER

12V BATTERY

GOOD ENGINE GROUND

GROMMET

+12v CONNECTION

RED

BLACK

+12v DASH

LIGHTING

GOOD

ENGINE

GROUND

WHITE

BLACK

WIRING

HARNESS

FUSE

(SEE CAUTION LEFT)

FIREWALL

OPTIONAL

SLIT TUBING

RECOMMENDED

(AVAILABLE AT MOST

HARDWARE STORES)

(for standard incandescent

lit instrument)

FOR INTERNAL LED

LIT INSTRUMENTS

WHITE

+12v DASH

LIGHTING

Power-Up

ADAPTER

PORT NUT

USE TEFLON

SEALING COMPOUND

ON PIPE THREADS

4" NPT ADAPTER

8" NPT ADAPTER

SMALL

GROMMET

NYLON TUBING

1

1

FERRULE

FERRULE

LOCK WASHER

THUMB NUT

OR

OR

FERRULE

COMPRESSION

NUT

COMPRESSION

NUT

CONNECT TO

12V LIGHTING

CONNECT TO

GOOD GROUND

Mounting and Connecting Mechanical Gauges

GROUND

INTERNAL LED

LIGHTED MODELS

+12 VOLT

LIGHTING

NOTE: DO NOT OVER TIGHTEN

ADAPTER FITTING OR

GAUGE MAY BE DAMAGED.

NOTE: DO NOT

LOOSEN PORT NUT

OR GAUGE MAY

BE DAMAGED.

MOUNTING

BRACKET

1. Gauges may be mounted in In-dash holes, or in Auto Meter custom mounting

Solutions. Secure gauge with mounting clamps supplied. 2-

1

⁄

16

" gauges mount

in 2-

1

⁄

16

" diameter hole.

2. Drill

3

⁄

8

" dia. holes and install rubber grommet where pressure line passes

through sheet metal, such as firewall.

3. Attach nylon pressure line to fitting on back of gauge using adapter, ferrule,

and compression nut as shown in diagram above. Route line through grommet

Connect the nylon line to the coiled copper tube attached to the exhaust

manifold using 1/8" connector.

4. Make sure line is free from hazard of moving parts or hot engine components.

It is recommended that Auto Meter 3224 copper tubing kit be used where a

potential hazard exits.

5. Start engine and thoroughly check installation for leaks.

6. Twist in light socket assembly and connect one wire to dash lighting circuit or

other 12V power source and the other wire to a good ground.