Brake pressure gauges, Nitrous pressure gauges, Warning – Auto Meter 4511 User Manual

Page 3

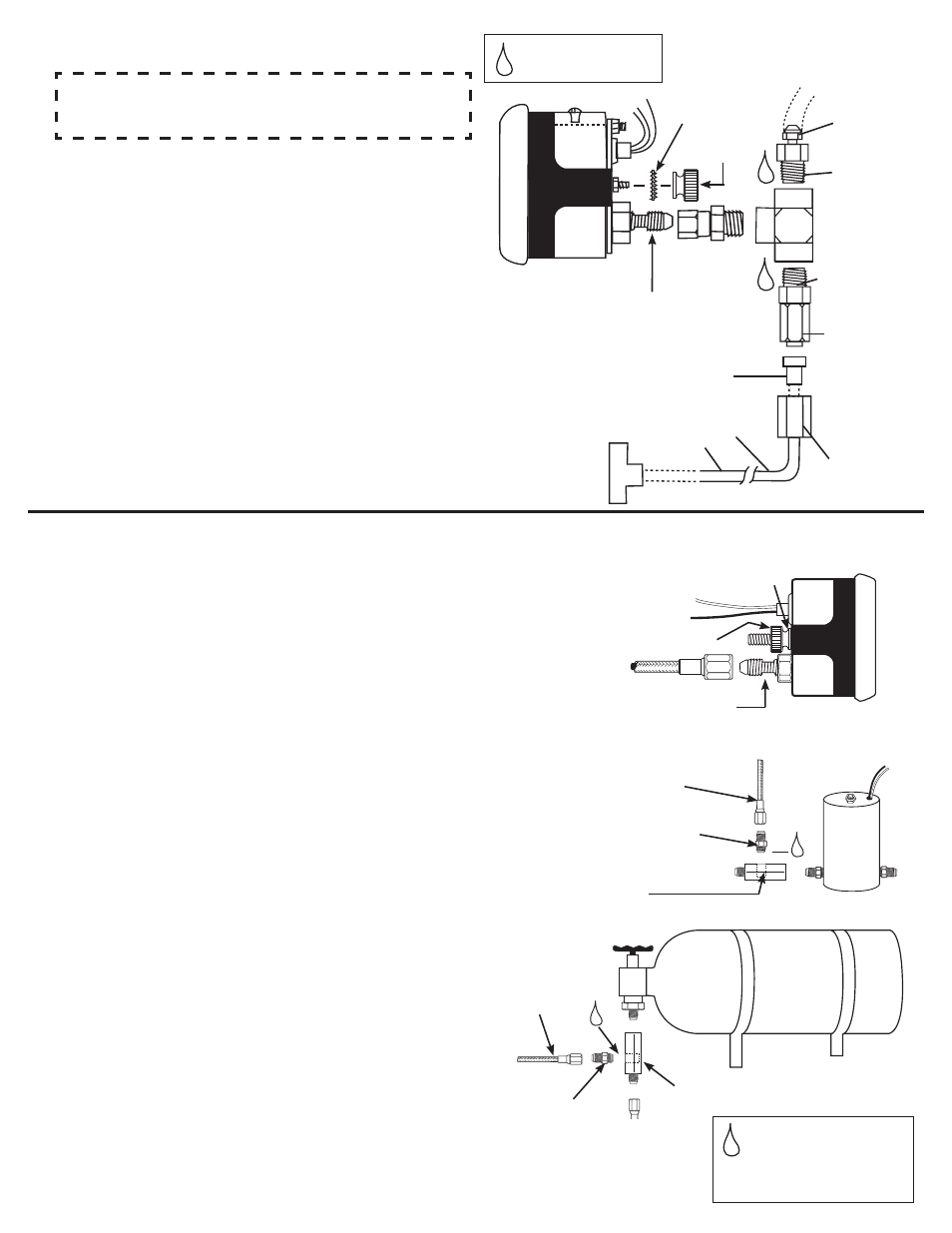

wARNINg: Use Teflon tape or sealant only where indicated.

Do not use oil on threads.

wARNINg: This gauge is supplied with a special restrictor fitting that

Must be installed on the braided line leading to the

nitrous gauge.

wARNINg: USE ONLY -4AN high pressure stainless steel braided

line when installing this gauge. All fittings must have a

minimum working pressure of 2000 psi.

1.

If you are not familiar with nitrous oxide systems and their

installations do not install this gauge. Have a qualified

mechanic install it for you.

2. Determine where the nitrous gauge will be mounted and the source

of the pressure (bottle outlet or nitrous solenoid inlet fitting). Then

determine the length of steel braided line required.

(Auto Meter offers three -4AN stainless steel braided line kits: Model

#3227- 3 feet, Model #3228- 6 feet, Model #3229- 4 feet)

3. Secure the -4AN stainless steel braided line to the back of the

gauge as shown in the illustration.

4.

Install gauge in appropriately sized dashboard hole or use under dash

panels. Secure gauge with the mounting bracket provided. NOTE: If

alternate gauge mounting is used other than in-dash or under dash,

mounting provisions may have to be determined by the installer.

5.

Make sure the nitrous bottle valve is closed.

6. Secure an in-line gauge adapter (eg. NOS part #16770 or #16771)

in a vice. Install the special restrictor fitting (supplied with gauge) in

the in-line gauge adapter. Do not over tighten as this may result in

stripped threads or a broken fitting.

7. Remove the main nitrous feed line from the bottle or the nitrous

solenoid. Install the in-line gauge adapter with the special restrictor

fitting either on the nitrous bottle or nitrous solenoid. Re-install the

main nitrous feed line. Install the braided line from the nitrous gauge

to the restrictor fitting.

8. Open the nitrous bottle valve.

NOTE: Test all fittings and hoses for any leakage. If any leaks are

detected, determine the cause of the leak and repair. Do not operate

vehicle if any leaks are detected.

Nitrous

Bottle

Nitrous

Solenoid

Special Restrictor

Fitting (Included)

Main

Nitrous

Feed

Special Restrictor

Fitting (included)

In-Line Gauge

Adapter

In-Line

Gauge Adapter

IN

OUT

Steel braided

line to gauge

Steel braided line to gauge

-4AN fitting with wrench flat.

(use caution, do not to over tighten)

Good Ground

To Dash 12V (+) Lighting

Brake Pressure gauges

wARNINg:

ONLY double flared steel brake line may be used to install this gauge. All

fittings you use must have a minimum working pressure of 2000 PSI.

Liquid

Air Pocket

Vent Screw

Use Teflon Sealing Tape

at Pipe Thread Joints

Bleed Tubing

Bleed

Screw

Bleed

Screw

Bushing

Tee

1

⁄

8

”-27

NPTF

Brake Line

Fitting

1

⁄

8” NPTF (Male)

x SAE 37˚ or 45˚ Male Flare

Sleeve

Nut

Double Flare

Steel Brake Line

to Tee in Brake

System

1. If you are not familiar with proper brake system bleeding

procedure, do not install this gauge. Have a qualified mechanic do

it for you.

2. Install gauge in appropriately sized dashboard hole or use under dash

panels. Secure gauge with the mounting bracket provided. NOTE: If

alternate gauge mounting is used other than in-dash or under dash,

mounting provisions may have to be determined by the installer.

3. Secure bleed screw, bleed screw bushing, and brake line fitting to the

tee provided with the gauge as shown above.

4. Secure the tee assembly from Step 3 to the gauge port. Be sure not to

over tighten as this can cause the movement to loosen in the case.

5. Install a tee at the brake system location suitable for your application.

6. Install steel double flare brake line between gauge and tee.

7. Connect WHITE light wire to the dash lighting circuit or other 12V

source. Connect the BLACK light wire to a suitable ground. (which

applicable)

8. Bleed your gauge and brake system using standard brake bleeding

procedure. If you are not familiar with brake bleeding procedure,

have a qualified mechanic install this gauge for you.

-4AN fitting with wrench flat.

(use caution, do not to over tighten)

Nitrous Pressure gauges

Use Teflon Sealing Tape or

Sealing Compound where

symbol indicates.

Thumb

Nut

Lockwasher

Mounting

Bracket

Use Teflon Sealing

Compound where

symbol indicates. (Tape

not recommended on

these threads)

THUMB NUT

LOCKWASHER

MOUNTINg

BRACkET

- 7303 2032 2021 2033 2022 880014 880011 880028 880025 3832 3803 3805 3831 3821 3807 3804 3605-00406 3632-00406 3621-00406 5931 5921 5903 5905 5932 5903-M 5907 5904 1432 7104 7103 7132 7108 7105 7107 7121 7131 4831 4832 4731 4884 4851 4741 4721 4732 4841 4821 4828 4728 4811 4711 4803 4704 4701 4813 4712 4801 4703 4720 7931 7984 7921 7908 6103-M 7932 7941 7911 7901 6104 6103 6132 6108 6105 6121 6131 7957 7948 1372 1332