Pressure, vacuum & boost gauges – Auto Meter 4511 User Manual

Page 2

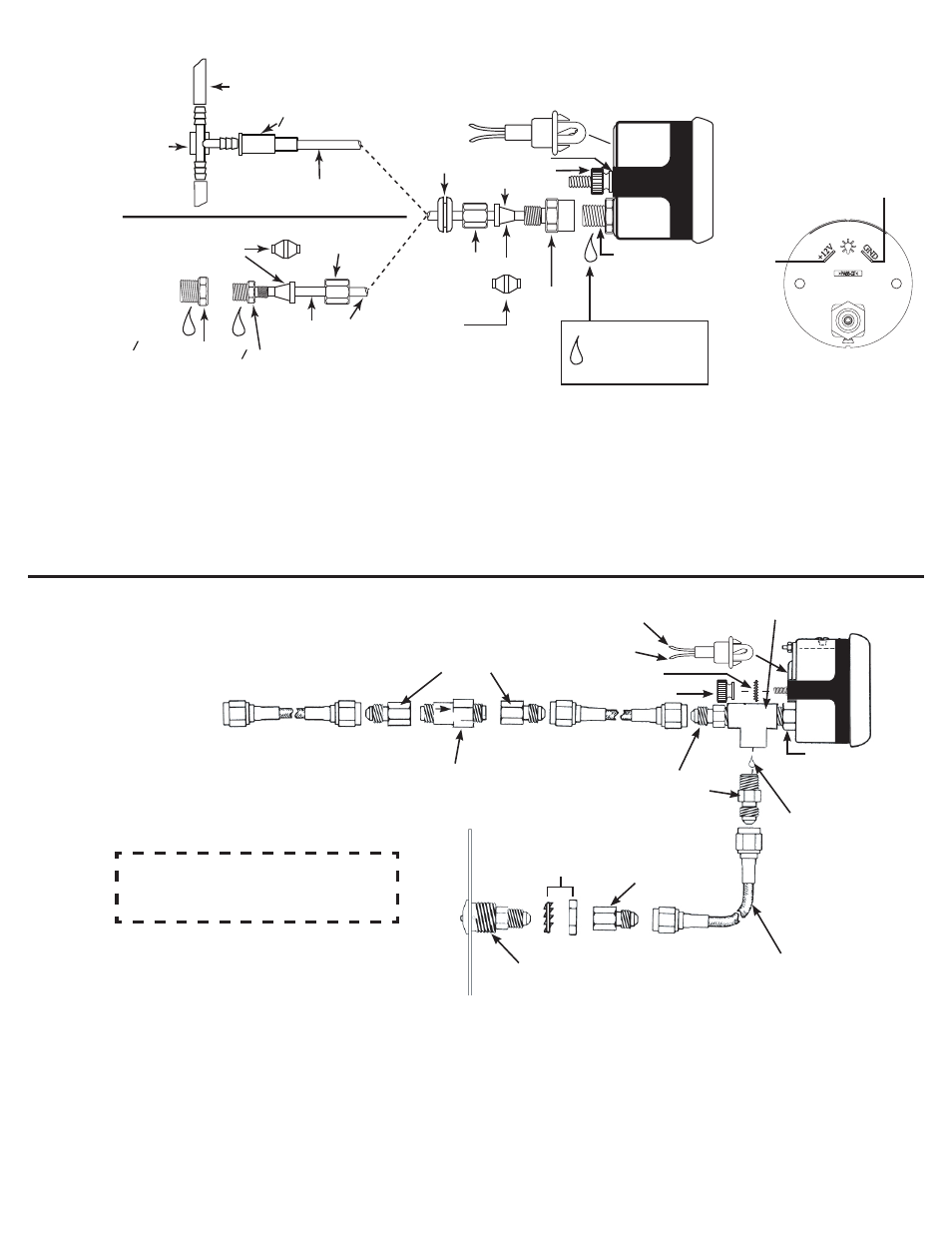

ADAPTER

USE TEFLON SEALINg

TAPE OR SEALINg

COMPOUND ON

PIPE THREADS

4" NPT ADAPTER

8" NPT ADAPTER

FOR PRESSURE

gAUgES ONLY

FOR VACUUM

AND BOOST

gAUgES ONLY

VACUUM HOSE

T-FITTINg

COMPRESSION

SMALL gROMMET

NYLON TUBINg

SEALINg NUT

8" CONNECTOR

1

NYLON TUBINg

1

1

CONNECT TO

12V LIgHTINg

CONNECT TO

gOOD gROUND

FERRULE

FERRULE

OR

OR

FERRULE

To Blower

Outlet Port

CHECK VALVE FLOW ARROW

MUST POINT TOWARD GAUGE

AFTER INSTALLATION

CONNECTOR

1

⁄

8

” NPTF (FEMALE)

x SAE 37˚

MALE FLARE

CONNECTOR

1

⁄

8

” NPTF (Male)

x SAE 37˚

Male Flare

FLOW

USE SEALING

COMPOUND ON ALL

PIPE THREAD JOINTS

BLOWER W/MEMORY

PLUMBING MUST

BE LEAK TIGHT TO

INSURE AN ACCURATE

MEMORY READING.

STAINLESS STEEL

BRAIDED TUBING

(TYPICAL)

HARDWARE

INCLUDED IN KIT

CONNECTOR

1

⁄

8

” NPTF (FEMALE)

x SAE 37˚

MALE FLARE

CONNECT TO GROUND

CONNECT TO 12V DASH LIGHTING

TEE

1

⁄

8

”-27

NPTF

THUMB NUT

LOCKWASHER

MOUNTINg

BRACkET

BLEED VALVE

5. Secure a

1

⁄

8

"

-27 NPTF female x SAE male flare connector to the bleed valve.

6. Using the nut and lock washer provided, secure the bleed valve and connector

assembly in-dash or wherever it is convenient for the driver.

7. Connect length of braided stainless steel tubing between the tee on back of

gauge and the bleed valve.

8. Start engine and thoroughly check for any leaks. When engine is shut off, gauge

should not leak down until bleed valve is pushed. If gauge leaks, check and

tighten all connections.

9. Connect the WHITE light wire to dash lighting circuit or other 12V source.

Connect the BLACK light wire to a good engine ground. (which applicable)

1. Secure two

1

⁄

8

"

-27 NPTF x #4 SAE 37˚ flare connectors to the

1

⁄

8

"

-27 NPTF

tee as shown in the installation above.

NOTE: The connector flare (37˚) must be compatible with the ends on the

stainless steel braided tubing. Auto Meter braided stainless steel

tubing no. 3227 and 3228 include #4 SAE 37˚ flare female swivel

ends.

2. Drill

3

⁄

8

"

dia. hole and install rubber grommet where pressure line passes

through firewall into engine compartment.

3. Secure two

1

⁄

8

"

-27 NPT female x SAE 37˚ male flare connectors to the check

valve as shown above. Secure the check valve and connector assembly to

one end of a length of braided stainless steel tubing.

NOTE: The arrow on the check valve must be pointing toward the gauge

as shown in the diagram above.

4. Secure the opposite end of the tubing and check valve assembly to the tee

on the back of the gauge. Route the pressure line through the firewall into

the engine compartment. Connect another length of braided stainless steel

tubing between the check valve and the blower outlet port.

NOTE: Keep line clear of moving parts or hot engine components.

Blower with Memory

NOTE: To insure accurate memory readings

DO NOT mount check valve directly to

gauge or blower. Excessive vibration

may cause leakage.

NOTE: Some late model vehicles use electronic sensors in their pressure and

temperature senders for engine control functions. Before removing the original

sender, we recommend that you contact your automotive dealer to be sure no

critical functions will be disrupted. With pressure gauges, it is beneficial to add

a T-fitting to install your new gauge and to keep the warning light operational.

This allows you to monitor the pressure and still have a warning light to indicate

emergency conditions.

1. Gauges may be mounted in In-dash holes, or in Auto Meter custom mounting

Solutions. Secure gauge with mounting clamps supplied. 2-

1

⁄

16

”gauges mount

in 2-

1

⁄

16

” diameter hole, 2-

5

⁄

8

” gauges mount in 2-

5

⁄

8

” diameter hole.

2. Drill

3

⁄

8

” dia. holes and install rubber grommet where pressure or vacuum line

passes through sheet metal, such as firewall.

3. Attach nylon pressure line to fitting on back of gauge using adapter, ferrule,

and compression nut as shown in diagram above. Route line through grommet

to engine compartment. Connect line to pressure port on engine by using

1

⁄

8

”

adapter (

1

⁄

4

” if needed), ferrule and compression nut for pressure gauges or

1

⁄

8

”

connector and T-fitting for vacuum and boost gauges.

4. Make sure line is free from hazard of moving parts or hot engine components.

It is recommended that Auto Meter 3224 copper tubing kit be used where a

potential hazard exits.

5. Start engine and thoroughly check installation for leaks.

6. Twist in light socket assembly and connect one wire to dash lighting circuit or

other 12V power source and the other wire to a good ground.

Pressure, Vacuum & Boost gauges

gROUND

INTERNAL LED

LIgHTED MODELS

MOUNTINg

BRACkET

THUMB

NUT

LOCkwASHER

+12 VOLT

LIgHTINg

PORT NUT

NOTE: DO NOT

LOOSEN PORT NUT

OR gAUgE MAY

BE DAMAgED.

NOTE: DO NOT OVER TIgHTEN

ADAPTER FITTINg OR

gAUgE MAY BE DAMAgED.

NOTE: DO NOT LOOSEN

PORT NUT OR GAUGE

MAY BE DAMAGED.

PORT NUT

NOTE: DO NOT OVER TIgHTEN

FITTINg OR gAUgE

MAY BE DAMAgED.

- 7303 2032 2021 2033 2022 880014 880011 880028 880025 3832 3803 3805 3831 3821 3807 3804 3605-00406 3632-00406 3621-00406 5931 5921 5903 5905 5932 5903-M 5907 5904 1432 7104 7103 7132 7108 7105 7107 7121 7131 4831 4832 4731 4884 4851 4741 4721 4732 4841 4821 4828 4728 4811 4711 4803 4704 4701 4813 4712 4801 4703 4720 7931 7984 7921 7908 6103-M 7932 7941 7911 7901 6104 6103 6132 6108 6105 6121 6131 7957 7948 1372 1332