Completing and staking the hip end frame, Fabric guide bracket – Anchor NAVI-TRAC LITE 20 WIDE User Manual

Page 11

NOTE: SEE APPENDIX 1,

FIG. 51 & 52 FOR X-CABLING

REQUIREMENTS IN UNITS

EXCEEDING 60’ IN OVERALL

LENGTH

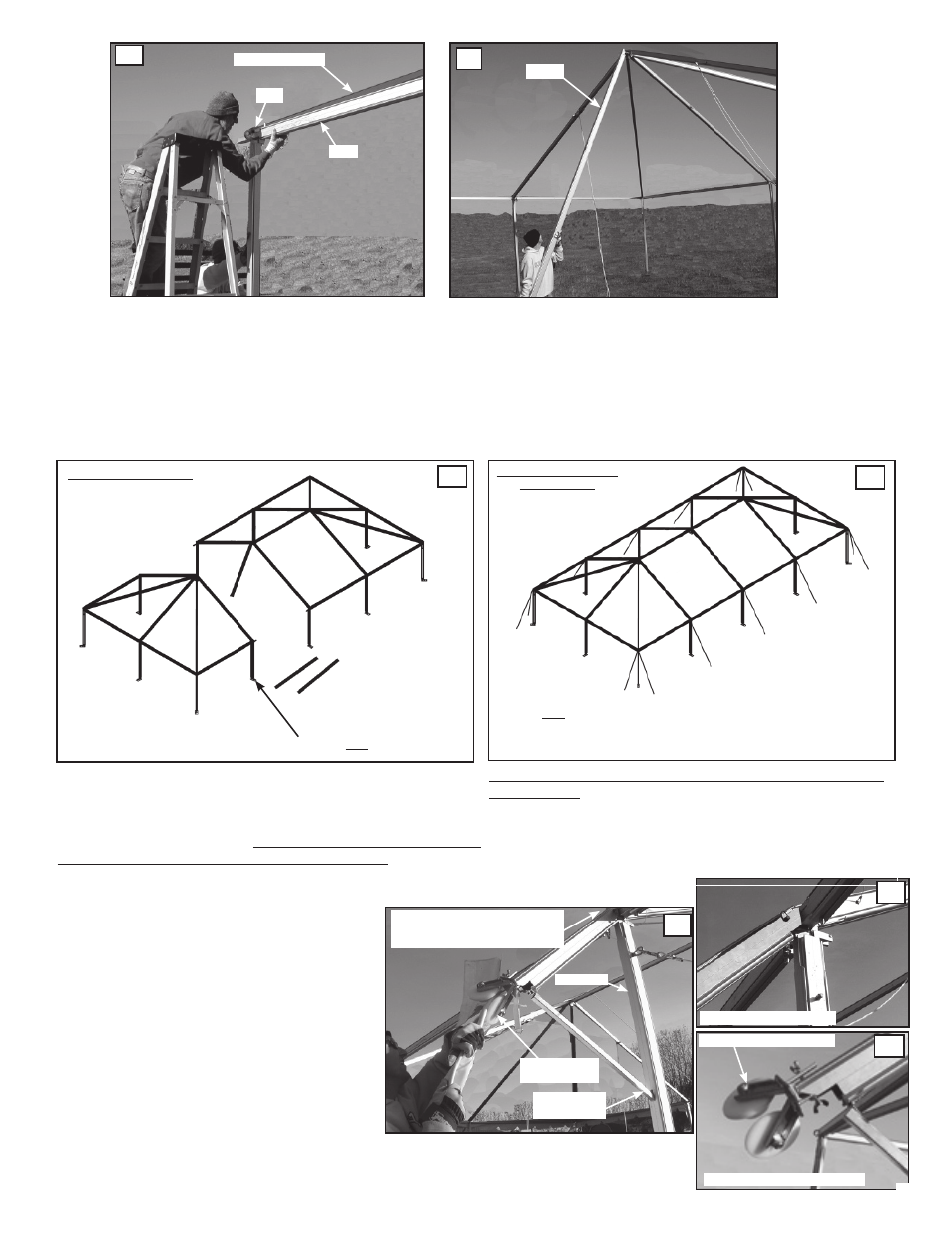

To finish out the unit, position a second, facing, hip end spaced 10’

from the last parallel middle beam and connect the purlins, ridge,

and eave bars just as in the preceding bay. Consult the blue print

for loading data for each baseplate location. Stakes alone may not

meet the loading requirement. It is the customer’s responsibility

to provide adequate anchoring to meet the loads.

Secure the new middle beam by attaching the Eave

Bars (E-10) from the standing beam to the mid beam’s

Eave Weldment as shown above.

Repeat this process with the Ridge w/Hooks (RG-10) as

shown above. Again, use the long Eave Bar Cradle to

attach the opposite end.

COMPLETING AND STAKING THE HIP END FRAME

The final middle bay joins with the cross beam of the opposite hip end (see fig. 28 & 29). Position the second (fac-

ing) hip end 10’ from the last middle beam, and use Eave Bars (E-10), and Ridge Bars w/ Hooks (RH-10) to con-

nect it to the standing frame structure.

E-10

MIDDLE BEAM

EW

RG-15

THE LAST MIDDLE BAY

HIP END UNIT WITH (2)

MIDDLE BAYS

FABRIC GUIDE BRACKET

Fabric is installed using the fabric wheeled guide

brackets and pull ropes thrown over the purlins

and eave bars from one side of the tent to the

other (see fig. 30).

To install the hinged Wheeled Guide Bracket,

slide the top over the external eye of the eave

weldment and pin in place using a Tension Lock

Pin. Spread the hinged bottom brace until the

lower end lodges in the tensioning slot of the

upright leg, as shown to the right (see fig. 31).

Using the butterfly set screws attach the Navi-Trac

Wheeled Panel Guide wheels into the open end

of the bracket at the hinged angle, as shown (see

fig. 32).

BOTTOM OF GUIDE BRACKET

TOP OF GUIDE BRACKET

Before installing fabric, all middle beams should be guyed

off, as shown. All guys are staked out from the upright at a dis-

tance equal to the height of the upright. If the breeze is strong,

the corner uprights should be guyed off as well. Later, the cor-

ner guys will be temporarily released while the fabric hip end is

being tensioned.

TENSIONING

SLOT

TOP OF BRACKET PINNED TO

THE OUTER EYE OF THE EAVE

WELDMENT

WHEELED

PANEL GUIDE

Fabric Kedar being fed between the angled

wheels of the panel guide.

WHEELED PANEL GUIDE

26

27

28

29

30

31

32

UPRIGHT

STAKE ALL BASE PLATES

STAKE ALL GUY CABLES

ACCORDING TO LOADS

SHOWN ON THE BLUEPRINT.

11