Obtaining hydraulic oil sample for analysis, Obtaining hydraulic oil sample 14.0 – JLG G9-43A (9151-4003) Operator Manual User Manual

Page 49

Form No. 20127 • G9-43A Owner/Operator Manual

1. Operate unit until hydraulic oil reaches normal operating temperature.

2. Apply parking brake, lower boom to rest and shift Forward/Reverse lever to

“Neutral” Observe Hydraulic Filter Bypass Indicator with engine running at

full throttle. Replace filter elements if necessary.

3. Obtain a container to receive waste oil and a CLEAN container to receive oil

sample.

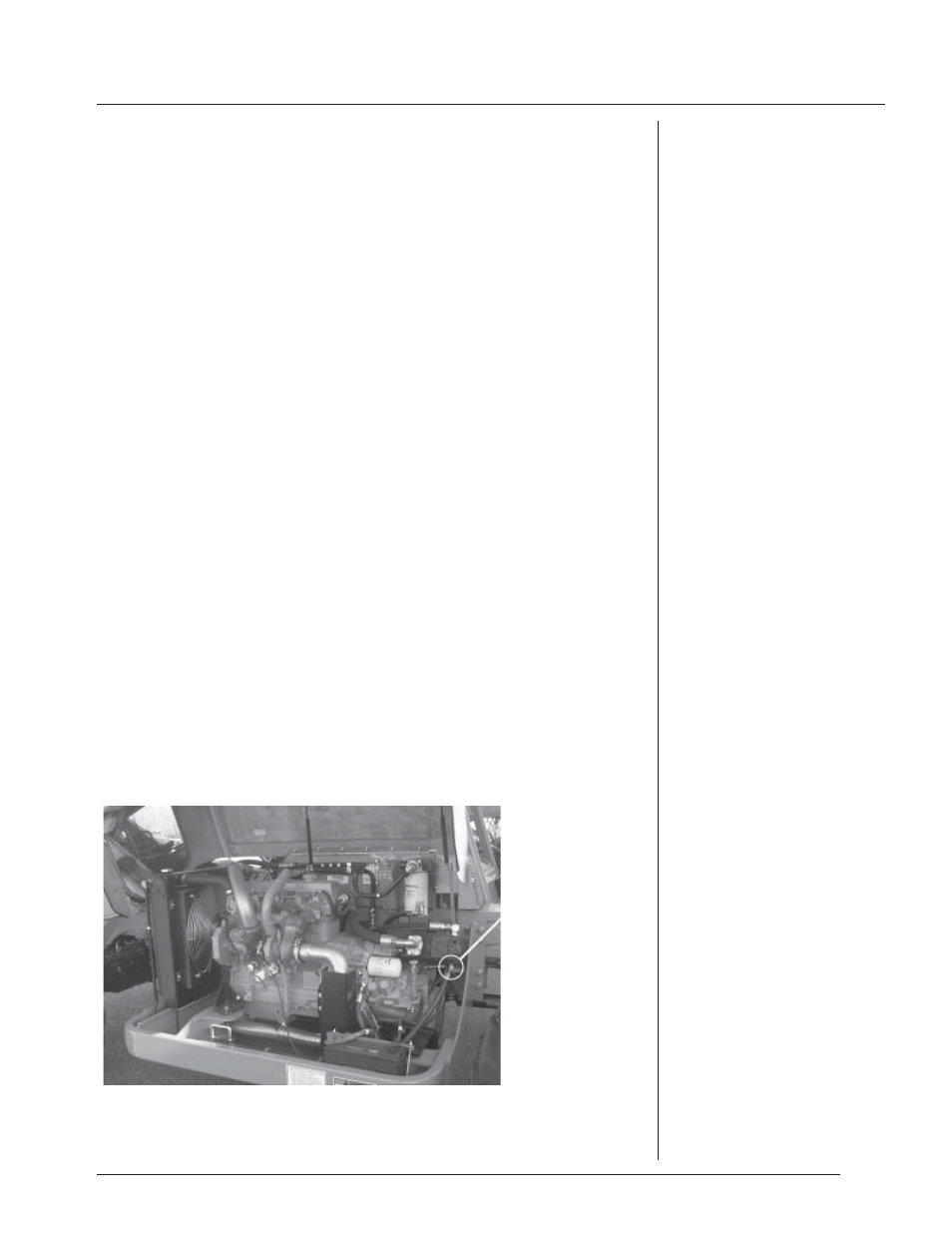

4. With gauge removed from hose, attach mini-check and hose to test port

located above implement pump (see diagram below). Hose end must be

positioned in waste oil container.

5. Allow at least one pint of oil to flow into waste oil container to eliminate any

contamination from hose.

6. Move hose to CLEAN container to collect sample for analysis.

7. Return hose to waste oil container and disconnect adapter from mini-check

test port.

8. Cover sample container immediately with CLEAN cap.

9. Stop engine and check oil level in reservoir and replenish as required. For

ease of filling reservoir, use a funnel with a hose or flexible tube for best

results.

10. Contact your GRADALL Distributor for information concerning oil analysis.

Oil sample containers are available from several sources:

• Oil companies

• Oil suppliers

• Sampling labs

Figure 14-1

OBTAINING HYDRAULIC OIL SAMPLE

14.0

NOTE!

OIL CLEANLINESS IS CRITICAL

The filtration system is designed

to maintain a minimum ISO

cleanliness level of 18/15.

TAKE HYDRAULIC

SAMPLE FROM

THIS PORT