Actuator maintenance, Coupler maintenance, Actuator maintenance -29 coupler maintenance -29 – JLG T350 Service Manual User Manual

Page 65

SECTION 3 - CHASSIS & TURNTABLE

3121198

– JLG Lift –

3-29

Actuator Maintenance

1. Frequently check brake fluid level (fluid must be

DOT3 or 4 approved, clean and uncontaminated).

2. Make sure mounting bolts are properly tightened 15

to 20 ft lbs (20 to 27 Nm) without deformation of cou-

pler.

3. Inspect entire actuator, replace any bent, worn or

damaged parts immediately.

4. Be constantly aware of systems braking quality,

make periodic checks as described in the brakes

owners manual. Consult certified brake specialist to

make necessary adjustments or repairs. Failure to

do so could result in loss of braking.

5. Be sure hydraulic lines and fittings are tight to avoid

fluid leaks.

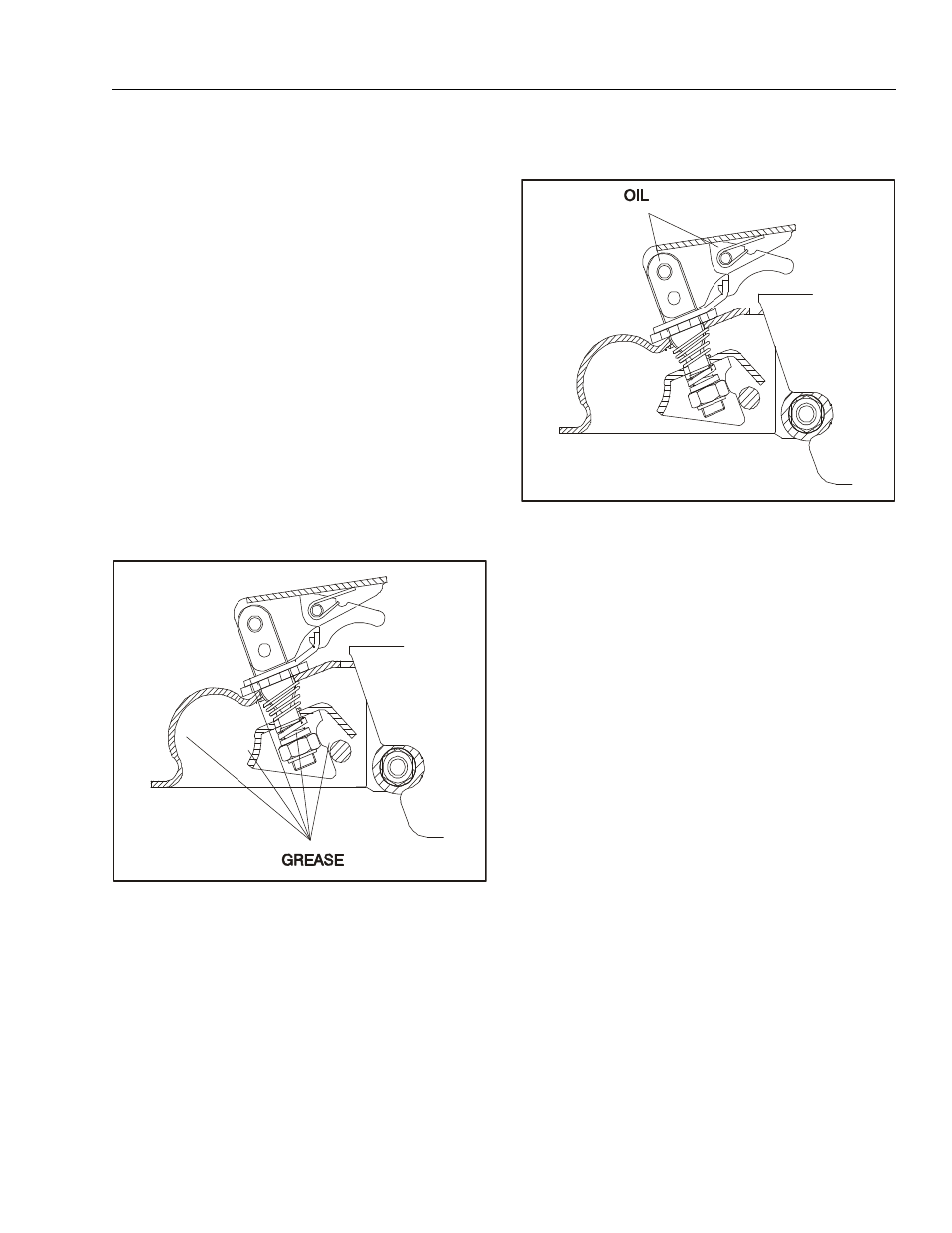

Coupler Maintenance

1. Maintain a film of automotive grease in the ball

pocket, ball clamp (front & back), ball clamp spring,

where link pin enters housing, and where the hous-

ing contacts the bracket hardware.

2. Maintain a film of oil on the pivot points and safety

latch spring using SAE 30W motor oil.

3. Keep the ball pocket and mechanism clean because

dirt, paint, etc. can hinder proper operation. When

parking or storing your trailer, keep the bracket and

coupler off the ground so dirt and/or other foreign

material will not build up in the coupler ball pocket.

4. Grease pivot hinge with automotive grease.