10 operator maintenance & lubrication, Operator maintenance & lubrication -4, Operator maintenance & lubrication diagram -4 – JLG T350 Service Manual User Manual

Page 18: Lubrication specifications -4

SECTION 1 - SPECIFICATIONS

1-4

– JLG Lift –

3121198

1.10 OPERATOR MAINTENANCE &

LUBRICATION

NOTE: Lubrication intervals are based on machine opera-

tion under normal conditions. For machines used in

multi shift operations and/or exposed to hostile envi-

ronments or conditions, lubrication frequencies must

be increased accordingly.

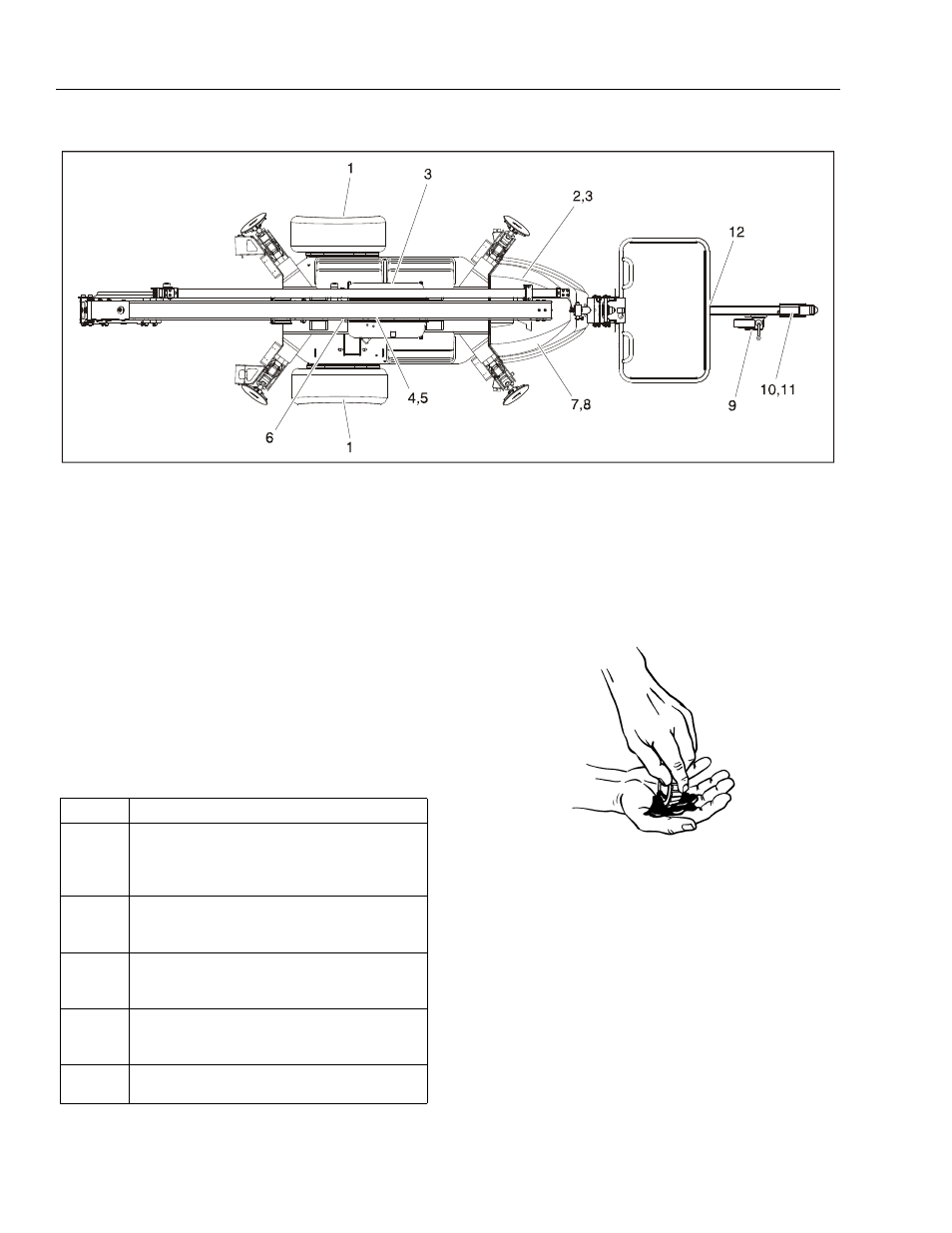

1. Wheel Bearings

Lube - MPG

Interval - every 12 months or 12,000 miles

Comments - Refer to Section 3.5, Hubs, Drums,

Wheel Bearings

1. Wheel Bearings

2. Hydraulic Oil

3. Hydraulic Filter & Breather

4. Swing Bearing

5. Swing Bearing Teeth

6. Swing Drive

7. Engine

8. Fuel Tank

9. Trailer Jack

10. Surge Brake

11. Coupler & Hitch Ball

12. Jockey Wheel Bearing

Figure 1-1. Operator Maintenance & Lubrication Diagram

Table 1-11.Lubrication Specifications

KEY

SPECIFICATIONS

MPG

Multipurpose Grease having a minimum dripping point of

350 degrees F. Excellent water resistance and adhesive

qualities; and being of extreme pressure type (Timken

OK 40 pounds minimum).

EPGL

Extreme Pressure Gear Lube (oil) meeting API

Service Classification GL-5 or Mil-Spec Mil-L-

2105.

HO

Hydraulic Oil. API Service Classification GL-3,

SAE 10W-20, Viscosity Index 152, e.g. Mobil-

fluid 424.

EO

Engine (crankcase) Oil. Gas - API SF/SG class,

MIL-L-2104. Diesel - API CC/CD class, MIL-L-

2104B/MIL-L-2104C.

OGL

Open Gear Lubricant - Mobiltac 375 or equiva-

lent.