JLG 660SJ ANSI Service Manual User Manual

Page 32

SECTION 1 - SPECIFICATIONS

1-14

– JLG Lift –

3120718

NOTES:

KEY TO LUBRICANTS

* Machines after S/N 38047 will have composite bushings and no grease fittings.

Lubrication intervals are based on machine operation under normal

conditions. For machines used in multi shift operations and/or

exposed to hostile environments or conditions, lubrication frequen-

cies must be increased accordingly.

** When changing oil in the Deutz oil cooled engine, drain both the crankcase and

the cooler. When refilling it is acceptable to overfill the crankcase (16 qts., capac-

ity of both crankcase and cooler combined). Start engine, allow the engine to run

until the thermostat opens (approximately 221 degrees F) cooler will fill up within

minutes; shut down and wait for approximately two minutes. Check oil level, fill oil

to max marking on the dipstick.

EO

EPGL

HO

MPG

Engine Oil

Extreme Pressure Gear Lube

Hydraulic Fluid (Mobil #424 or equivalent)

Multi-Purpose Grease

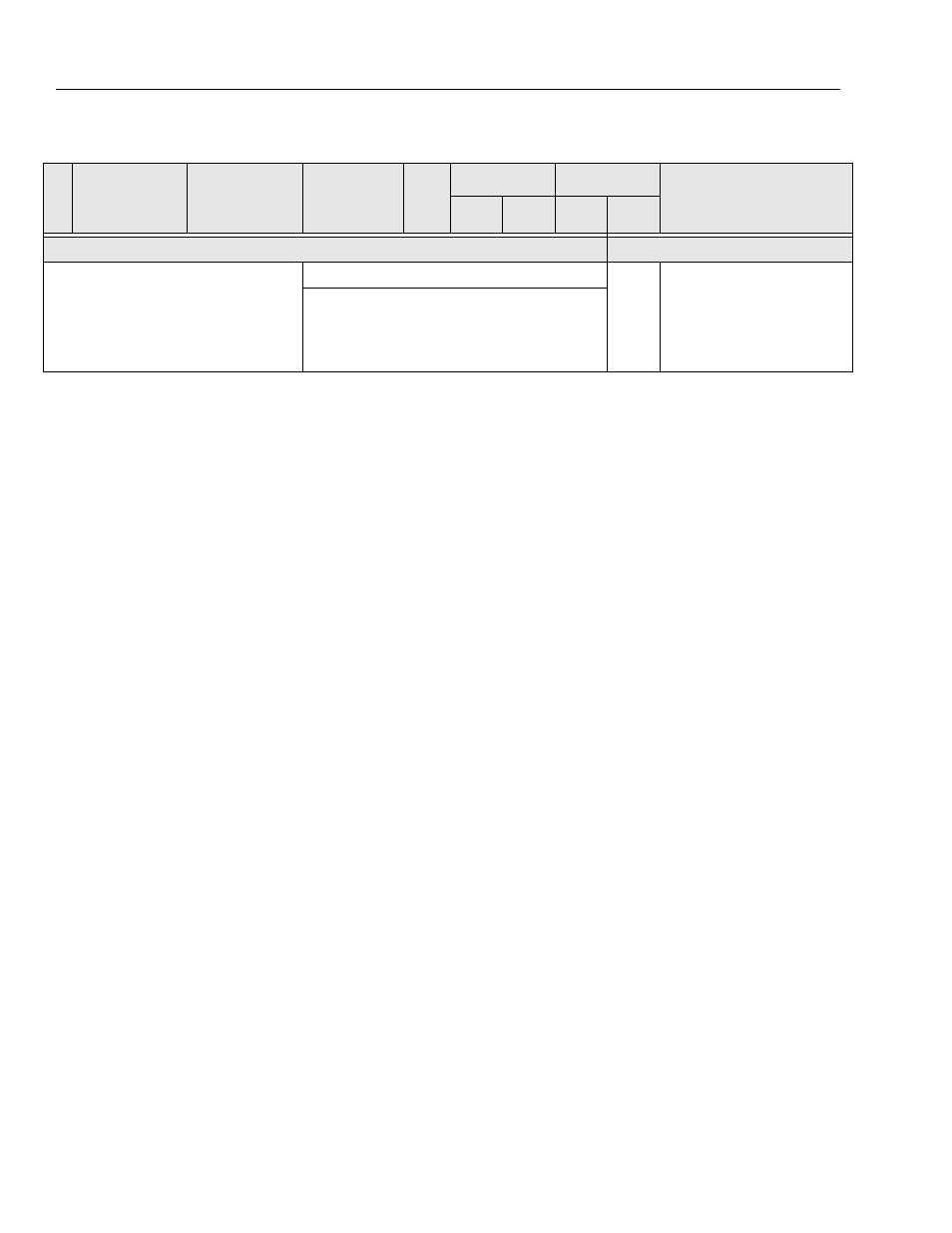

Table 1-12. Lubrication Chart - S Models

Components

Number/Type

Lube Points

Capacity

Lube

Interval

Hours

Comments

3 Months

150 hrs

6 Months

300 hrs

1 Year

600 hrs

2 Years

1200 hrs