Advance Adapters 713091 User Manual

Page 2

ADVANCE ADAPTERS INC.

P/N: 713091

P.O. Box 247, 4320 Aerotech Center Way

New Item: (08/02)

Paso Robles, CA 93447

PAGE 2 OF 4

Telephone: (800) 350-2223

Fax: (805) 238-4201

Page Rev. Date:

09-18-02

SPECIAL NOTE:

The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the components will void

any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion, we strongly recommend that

you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter components. We recommend that a service

manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment. These manuals are normally available at automotive dealerships

and parts stores.

CHEVY V8 TO JEEP TJ WELD-IN MOUNT

REPLACING THE STOCK 6 CYL.

alignment pin, C-clamp the mounts to the inside of the frame (the front-to-back angle of the mounts will be determined

later).

Install the new Chevy rubber mounts onto the engine block and install the saddle mount. As you set the Chevy block

into the TJ frame rails you'll notice that you will have about an inch window for front-to-rear mounting options.

Place the engine in the engine compartment. The forward-to-rear location of the engine is to be determined by you

and by the drivetrain you have chosen. Also, keep in mind header or manifold clearance when positioning the engine.

When a suitable location is found, rotate the doweled frame mounts so they hit parallel to the engine saddle mount

mounting flange. Tighten the C-clamp and/or tack weld them in place. The frame brackets must also have two holes

drilled for mounting to the saddle mount. Before removing the engine, mark the two hole locations on both frame

brackets where the saddle meets the frame brackets. These holes need to fit a 3/8" bolt. Remove the engine

assembly and fully weld the mounts to the frame, then drill the mounting holes.

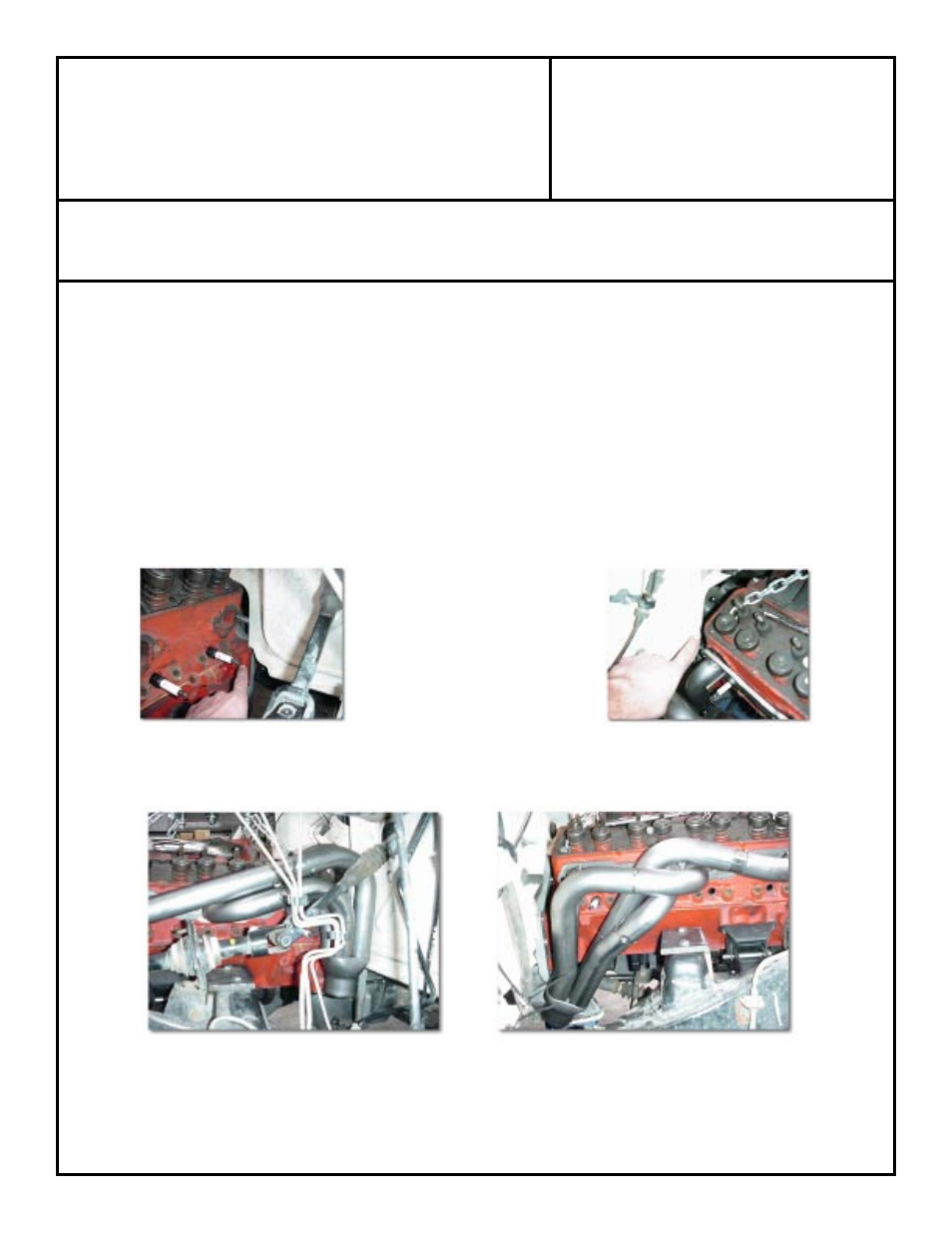

Headers will require firewall modifications in the furthest back location, but work great in the forward location. Also,

the passenger side header may require some clearance with certain starters (on solenoid housing). A heat shield and/

or a mini hi-torque starter is recommended.

Both the driver's side and

passengers side firewall to

tunnel seam will need to be

cut or folded over for both

transmission and exhaust

clearance.

P/N 717090 headers installed.