Advance Adapters 477021 User Manual

Page 5

ADVANCE ADAPTERS INC.

P/N: 477021

P.O. Box 247, 4320 Aerotech Center Way

New Item: (12-01)

Paso Robles, CA 93447

PAGE 5 OF 14

Telephone: (800) 350-2223

Fax: (805) 238-4201

Page Rev. Date:

02-23-11

SPECIAL NOTE:

The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the components

will void any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion, we

strongly recommend that you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter

components. We recommend that a service manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment.

These manuals are normally available at automotive dealerships and parts stores.

TOYOTA LOW GEAR 4.7:1 21 SPLINE

For Gear-Driven Transfer Cases ONLY

Installation Tips:

For those who do not have access to a mill, here is an easy way to clearance your reduction

housing. This procedure requires only some marking fluid and a small angled grinder. This should take you about

1 hour, but remember to take your time and do it slowly. If you do not feel comfortable making these modifications,

we offer

P/N 51-5911

. This is a heavy duty housing that has been pre-clearanced for these gear sets.

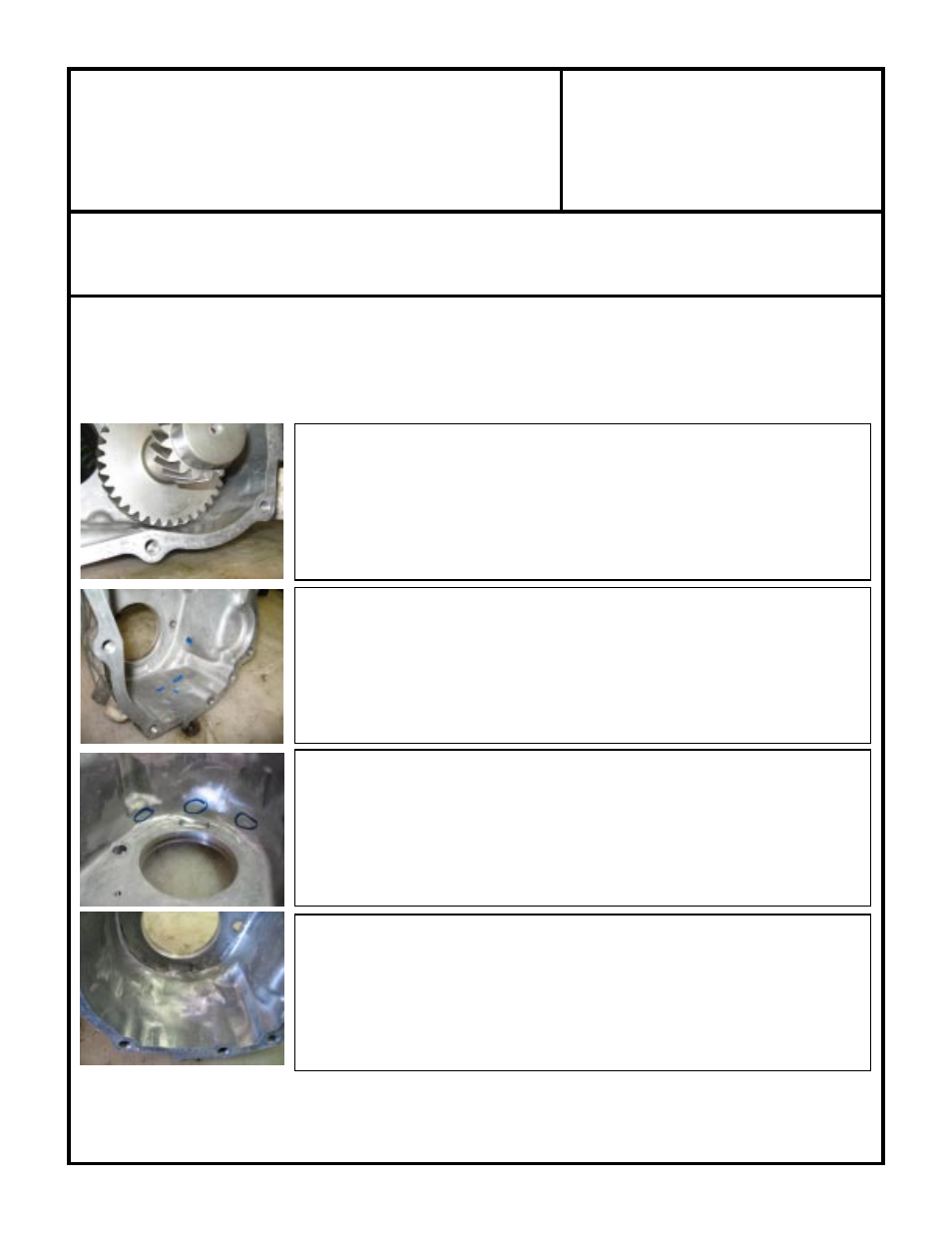

First, test fit your new gear set into your reduction housing. You will notice that the

gears will interfere with the casting in multiple locations. Lightly tap the gear into

the casting. This will score the casting at the interference locations. Now using

marking fluid (paint pen, permanent marker, etc.), take the time to carefully mark

all locations where contact is made.

Now that all your marks have been made, it's time to start slowy removing material

from the casting. Using the grinder equipped with a 50 grit disc, begin to work away

at your marked areas. Remember to take mental note of how much each section

of the casting was contacting the gear. Take special care at this point not to remove

too much material.

After the marked areas have been ground away, go ahead and re-test fit the gears

back into the housing. Make sure to rotate the gear and that it has 360 degree

clearance with all areas of the housing. At this point, it may be necessary to re mark

areas where the gear is still contacting the housing. Repeating this procedure a few

times will insure proper fit and you will avoid the possibility of grinding a hole through

the casting.

With all the grinding done, test fit the gear set one last time making sure that every

thing spins freely and that there are no hang ups or tight spots. In addition to the

case, also remember that the shift rails will require some modifications due to gear

interference. This would be the optimal time to complete this procedure as well.

Make sure that the shift detents are installed to insure proper shift location for

modifications to be made.