Advance Adapters 716131-E User Manual

Page 2

JEEP 727 & 999 TORQUEFLITE TO CHEVY

ENGINES (REPLACING AMC 6 CYL.)

ADVANCE ADAPTERS INC.

P/N: 716131

P.O. Box 247, 4320 Aerotech Center Way

Paso Robles, CA 93447

PAGE 2 OF 4

Telephone: (800) 350-2223

Fax: (805) 238-4201

Page Rev. Date:

05-14-09

SPECIAL NOTE: The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the components

will void any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion, we strongly

recommend that you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter components.

We recommend that a service manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment. These manuals are

normally available at automotive dealerships and parts stores.

2. The adapter plate can now be bolted to the new engine. Be sure to use the stock GM

dowel pins for alignment between the adapter plate and engine block. The two stud

bolts that are provided must be installed into the engine block just below the two stock

dowel pins. After the adapter plate is installed, the lock washers and nuts can then be

installed through the small access slot.

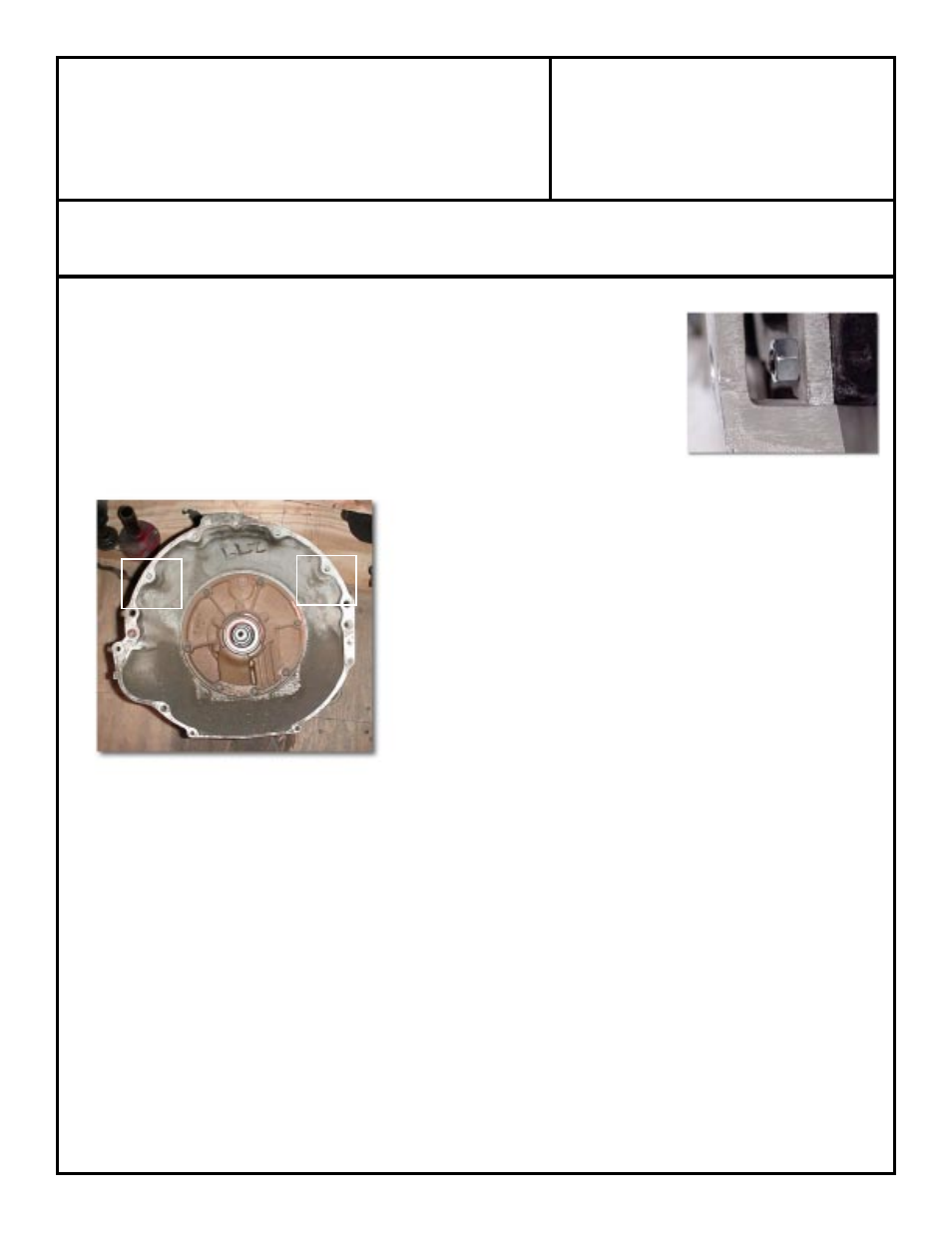

Due to the close proximity of the AMC and GM bolt patterns on our adapter

plate, you will be required to adjust two holes on your stock transmission. The

two holes in the transmission bellhousing (photo below) will need to be elongated

slightly with a rat tail file to match our adapter plate.

Two special dowel pins have been furnished for aligning the

transmission to the adapter plate. These dowel pins provide must be

installed into the Torqueflite transmission. These pins have a slight

diameter change of only .003". The larger diameter must be lightly

tapped into the transmission case ( care should be taken to tap these

in as straight as possible. The small end of the dowel pin will

protrude out of the case for indexing into the our adapter plate.

3. Pilot the aluminum torque converter ring onto the torque convert.

Line up the holes on the ring to the torque convert bosses. Verify the

thread pitch needed and bolt the ring to the torque converter. Thread

retainer and flat washers should be used.

On the 1991 & earlier Jeep

torque converter bolt patterns, the torque converters had either a

5/16" or 3/8" bolt thread. Our aluminum ring has been drilled with

clearance holes for 5/16" bolts only. If your torque converter

requires a 3/8" bolt size, then you will need to drill the holes in the

aluminum ring to fit the 3/8" torque converter bolts. If this is

necessary, this should be done on a drill press, and a 13/32" drill

bit should be used.

4. Once the transmission has been modified, you can begin the assembly process.

5. Assemble the transmission to engine assembly using the new transmission dowel pins for proper alignment. These

components should slide together. If interference prevents you bolting the units together, YOU SHOULD NOT PULL

COMPONENTS TOGETHER WITH THE BOLTS. Check for interference and/or verify the measurement of your stock

engine and flexplate. Please call our technical sales department if your not sure of the interference problem.

6. Once the engine and transmission are assembled, the fleplate to converter bolts must be accessed through the lower portion

of the bellhousing and adapter. The torque converter must be pulled forward towards the engine and rotated to match the

bolt pattern of the stock flexplate. The converter must move a minimum space of .100" to meet the flexplate. This will

allow the necessary transmission front pump clearance.

CAUTION:

If no clearance is provided, the pump area of

the transmission will be destroyed. Most flex plates are dual drilled to GM TH350 and TH400 torque converters. Our

r

r