Daily inspection and maintenance, Daily inspection and maintenance table 7-1, Daily inspection and maintenance table, 7-1 – Snorkel MHP34J(Bi-Energy Option) User Manual

Page 37: Operators daily inspection, 7-1, Inspection and maintenance table, 7-1, Qualified, 7-1, 8-2, Daily inspection and maintenance table -1, Danger

7. Daily Inspection and Maintenance

At the start of each work day (or 8 hour shift), an

MHP12/34J qualified operator must perform the

Daily Inspection and Maintenance as listed in the

table below.

The purpose of the Daily Inspection and Mainte-

nance is to keep the MHP12/34J in proper working

condition and to detect signs of malfunction at the

earliest possible time.

The MHP12/34J should be in the STOWED

POSITION and the Master Key Switch set to OFF

before you begin this inspection.

Defective parts and/or equipment malfunctions

jeopardize the safety of the operator and other per-

sonnel, and can cause damage to the machine.

DO NOT operate an MHP12/34J that is known

to be damaged or malfunctioning.

R e p a i r

a l l

e q u i p m e n t

d a m ag e

o r

malfunctions, before placing the MHP12/34J

into service.

MHP12/34J – 11447A

page 7 - 1

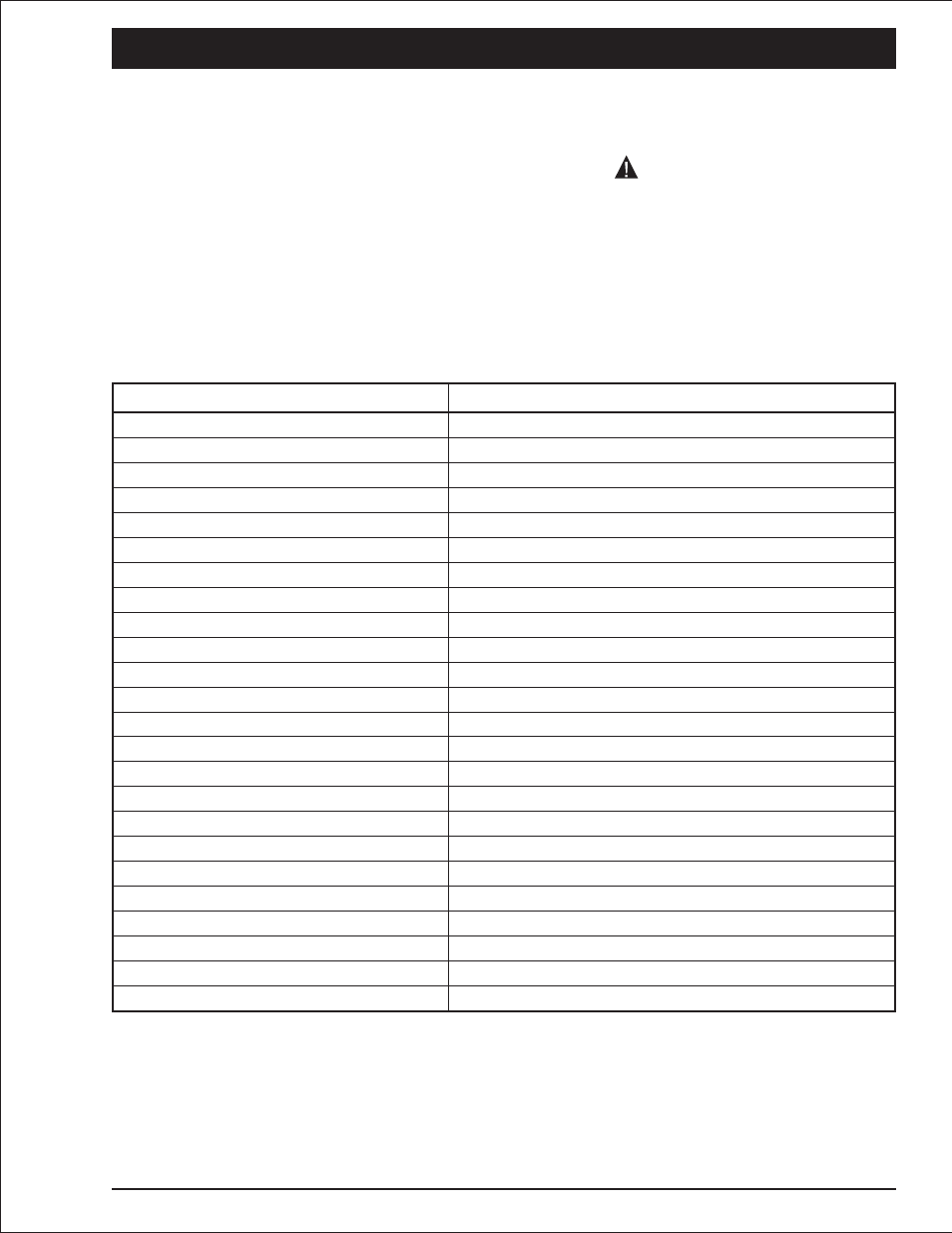

Item

Service Required

Engine fuel level

Look to see that the fuel tank is full

Fuel tank cap

Check to see that the cap is tight

Engine oil level

Check oil level (between dipstick lines)

Fuel leaks

Visually inspect (hoses and connections)

Engine coolant

Check that grills are not blocked

Wiring harnesses

Visually inspect (installation, condition)

Battery terminals

Visually inspect (no corrosion)

Battery fluid level

Check fluid level (1/4" or 6 mm below filler neck)

Hydraulic oil level

Visually inspect level (between lines on gauge)

Hydraulic oil leaks

Visually inspect (hoses, tubes)

Tires and wheels

Visually inspect (condition)

Bolts and fasteners

Visually inspect (condition)

Structural damage and welds

Visually inspect (weld cracks, dents)

Lanyard anchor points

Visually inspect (condition)

Platform gravity gate

Check condition and operation

Platform guardrails

Visually inspect (condition)

Flashing light (option)

Visually inspect (operation)

Ground control switches

Actuate and inspect for proper operation

Level sensor (option)

Check operation

Emergency lower

Check operation (causes correct motion)

Platform control box switches

Actuate and inspect for proper operation

RCD/ELCB AC outlet (option)

Check operation

Platform work lights (option)

Check operation

Placards and decals

Visually inspect (installation, condition)

■

Daily Inspection and Maintenance Table

DANGER