Fluid filter, Hoses, tubes, and fittings, Tires and wheels – Snorkel AB60J User Manual

Page 37: Lower control station, Operating controls, Danger

Chapter 7 – Prestart Inspection

AB60J – 0181972

33

Punctures caused by bolts, screws, or nails are not a

problem for foam filled tires.

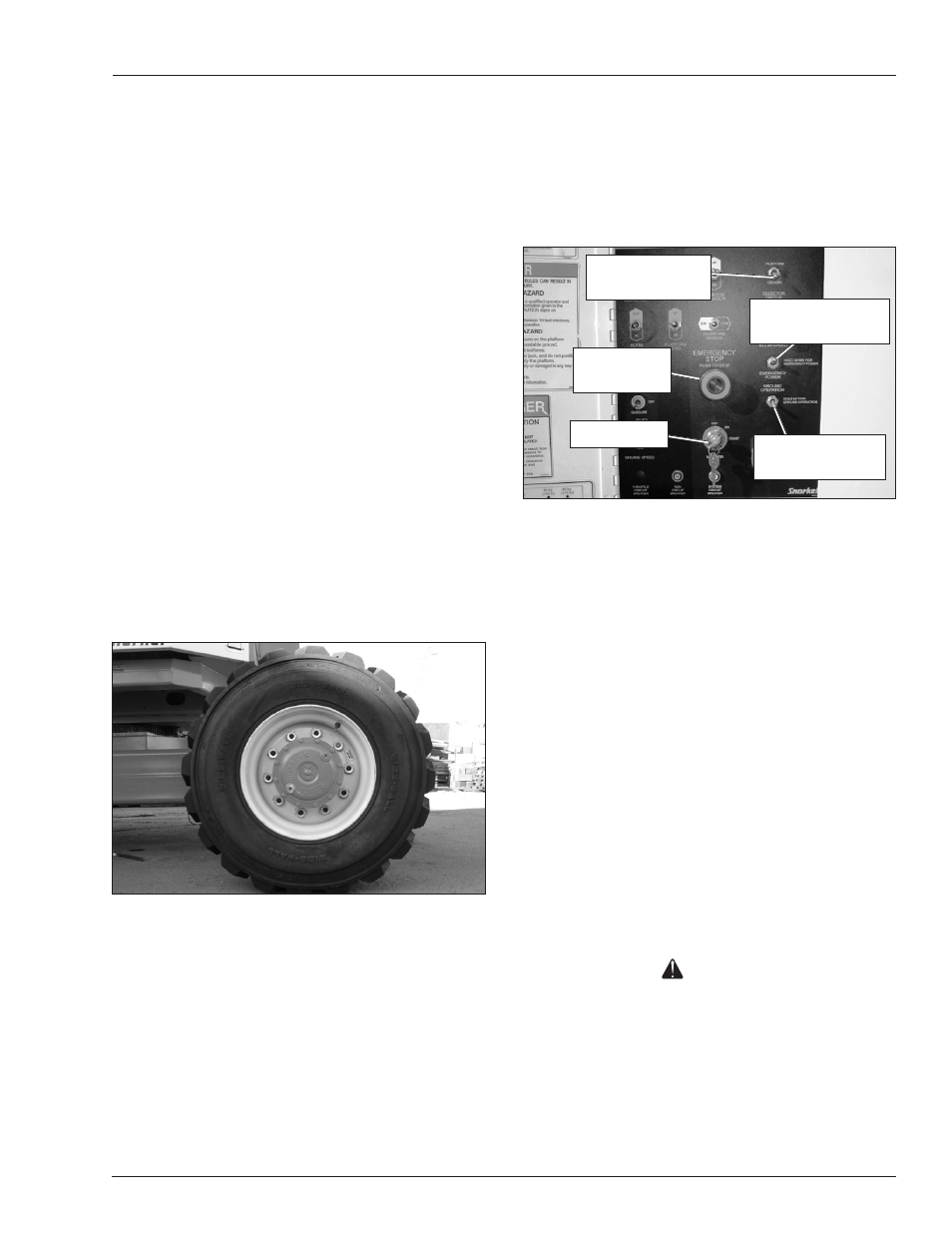

Lower Control Station

With no personnel or materials in the platform, test the

operation of each control from the lower controls (refer

to Figure 7.10).

Figure 7.10 – Lower Controls

Operating Controls

Use the following procedure to operate the machine from

the lower controls.

1. Turn the battery disconnect switch on.

2. At the lower controls, pull the emergency stop button

outward. Place the control selector switch in the lower

control position.

3. Insert the key into the start switch and turn the switch

to the start position until the engine starts, then re-

lease it to on.

Note

If the machine has a GM engine, there will be a 7 to 10

second delay after starting the engine, before the throttle

will go to mid or high. Start the engine and wait 10 seconds

before proceeding with machine operation.

4. Let the engine warm to operating temperature.

5. Hold the ground operation switch upward.

Danger

Pinch points may exist between moving components.

Death or serious injury will result from becoming

trapped between components, buildings, structures,

or other obstacles. Make sure all personnel stand

clear of the aerial platform while preforming prestart

inspection.

5. The sight glass on the reservoir has an internal

thermometer to measure the fluid temperature. The

temperature should be less than 200°F (93°C).

Fluid Filter

Checking the condition of the hydraulic fluid filter is part

of the machine maintenance schedule and should not be

performed by the operator.

Hoses, Tubes, and Fittings

To inspect the hoses, tubes and fittings:

1. Inspect all hydraulic hoses, tubes, and fittings for

wear, leakage, or damage (refer to Figure 7.8).

2. Make sure the hoses are properly routed to avoid

sharp edges, kinking, and scuffing.

3. Inspect the tubes for dents or other damage that may

restrict fluid flow.

4. Make sure all hoses and tubes are held firmly in their

support brackets.

5. Check under the chassis for fluid that has leaked. Hy-

draulic fluid leaks are easily visible on the ground.

Tires and Wheels

Visually inspect the tires and wheels (refer to Figure 7.9)

to make sure they are suitable for service.

Figure 7.9 – Tires and Wheels

Foam filled tires do not have a pressure decal or a valve

core.

To inspect foam filled tires and wheels:

1. Check the wheel lug nuts to see that none are miss-

ing, damaged, or loose.

2. Carefully inspect for large holes or cuts where foam

is coming out of the tire.

3. Look for large imbedded objects, such as angle iron,

that can rip a tire open.

Note

Emergency

Stop Button

Control Selector

Switch

Ground Operation

Switch

Start Switch

Engine/Emergency

Power Switch