Battery fluid level, Battery terminals, Cables and wiring harness – Snorkel AB60J User Manual

Page 36: Hydraulic system, Fluid level, Danger, Caution

Chapter 7 – Prestart Inspection

32

AB60J – 0181972

Hydraulic System

Hydraulic power is supplied from an engine driven vari-

able displacement piston pump.

Danger

Hydraulic fluid escaping under pressure can have

enough force to inject fluid into the flesh. Serious

infection or reaction will result if medical treatment is

not given immediately. In case of injury by escaping

hydraulic fluid, seek medical attention at once.

The hydraulic reservoir is behind the door on the right side

of the turntable. The pump is mounted on the engine.

Fluid Level

To inspect the fluid level:

1. Place the aerial platform on a level surface with the

platform fully stowed.

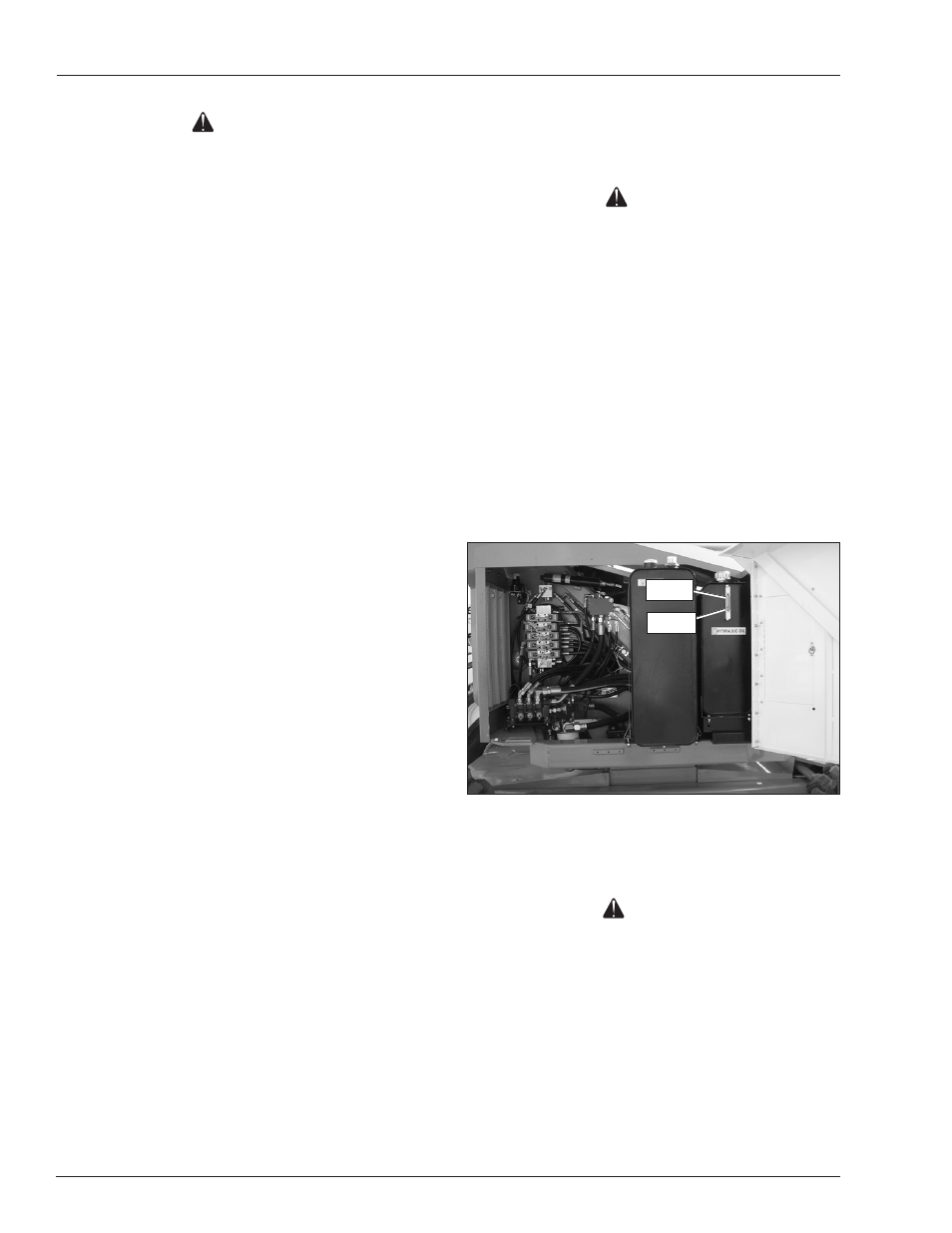

2. Open the door on the right side of the chassis to ac-

cess the hydraulic fluid level gauge (refer to Figure

7.8).

Figure 7.8 – Hydraulic Fluid Gauge

3. Make sure the fluid level is between the minimum

and maximum lines.

Caution

Not all hydraulic fluid is suitable to use in the hydrau-

lic system. Some have poor lubricating character-

istics and may increase component wear. Only use

hydraulic fluid as recommended.

4. If necessary, remove the filler cap and add fluid of

the proper type. Replace the cap making sure it is

tightly in place.

Note

Refer to Chapter 2 for the proper type and grade of

hydraulic fluid to use. The need to regularly add fluid

indicates a leak that should be corrected.

Full

Add

Full

Add

Caution

Even with low voltage electrical systems, severe

arcing can occur. Electrical shock or component

damage may result from contact with energized

conductors. Use caution when working with any

electrical device.

The battery is automatically charged when the engine is

running. Include the battery when inspecting and servicing

the electrical system.

For optimal battery performance the battery fluid level

must be maintained and the battery connections must

be kept clean.

Battery Fluid Level

To inspect the battery fluid level:

1. Remove the caps from the battery (refer to Figure

7.7).

2. Visually check the battery fluid level making sure the

level is within ¼″ (6 mm) of the bottom of the filler

neck inside each hole.

3. If necessary, add distilled water.

Note

Use only distilled water when refilling the battery. Tap

water may contain metallic solids such as iron which can

reduce the life of the battery.

4. Replace the caps on the battery. The caps must be

in place and tight during machine operation.

Battery Terminals

To inspect the battery terminals:

1. Check the top of the battery, the terminals, and cable

ends (refer to Figure 7.7). They should be clean and

free of corrosion.

2. If necessary, clean the top of the battery. Clean the

terminals and cable ends with a wire brush or terminal

cleaning tool.

3. Make sure all cable ends are securely fastened to

the terminals.

Cables and Wiring Harness

To inspect the cables and wiring harness:

1. Visually inspect all cables and wiring for wear and/or

physical damage such as loose connections, broken

wires, and frayed insulation.

2. Check the wiring in areas where a change in routing

direction may cause them to become pinched.

3. Make sure the cables and wires are properly routed

to avoid sharp edges, pinching, and scuffing.