Bryant R-410A 583B User Manual

Page 9

A.

Adhere to the following criteria when selecting,

sizing, and installing the duct system:

1. Units are shipped for side shot installation.

2. Select and size ductwork, supply-air registers, and return-air

grilles according to American Society of Heating, Refrig-

eration and Air Conditioning Engineers (ASHRAE) recom-

mendations.

3. Use flexible transition between rigid ductwork and unit to

prevent transmission of vibration. The transition may be

screwed or bolted to duct flanges. Use suitable gaskets to

ensure weather tight and airtight seal.

4. All units must have field-supplied filters or accessory filter

rack installed in the return-air side of the unit. Recom-

mended sizes for filters are shown in Tables 2 and 3.

5. Size all ductwork for maximum required airflow (either

heating or cooling) for unit being installed. Avoid abrupt

duct size increases or decreases or performance may be

affected.

6. Adequately insulate and weatherproof all ductwork located

outdoors. Insulate ducts passing through unconditioned

space, and use vapor barrier in accordance with latest issue

of Sheet Metal and Air Conditioning Contractors National

Association (SMACNA) and Air Conditioning Contractors

of America (ACCA) minimum installation standards for

heating and air conditioning systems. Secure all ducts to

building structure.

7. Flash, weatherproof, and vibration-isolate all openings in

building structure in accordance with local codes and good

building practices.

X.

INSTALL ELECTRICAL CONNECTIONS

WARNING: The unit cabinet must have an uninter-

rupted, unbroken electrical ground to minimize the pos-

sibility of serious injury if an electrical fault should occur.

This ground may consist of an electrical wire connected

to the unit ground lug in the control compartment, or

conduit approved for electrical ground when installed in

accordance with NEC (National Electrical Code) ANSI/

NFPA 70 (latest edition) (in Canada, Canadian Electrical

Code CSA (Canadian Standards Association) C22.1) and

local electrical codes. Do not use gas piping as an

electrical ground. Failure to adhere to this warning could

result in serious injury or death.

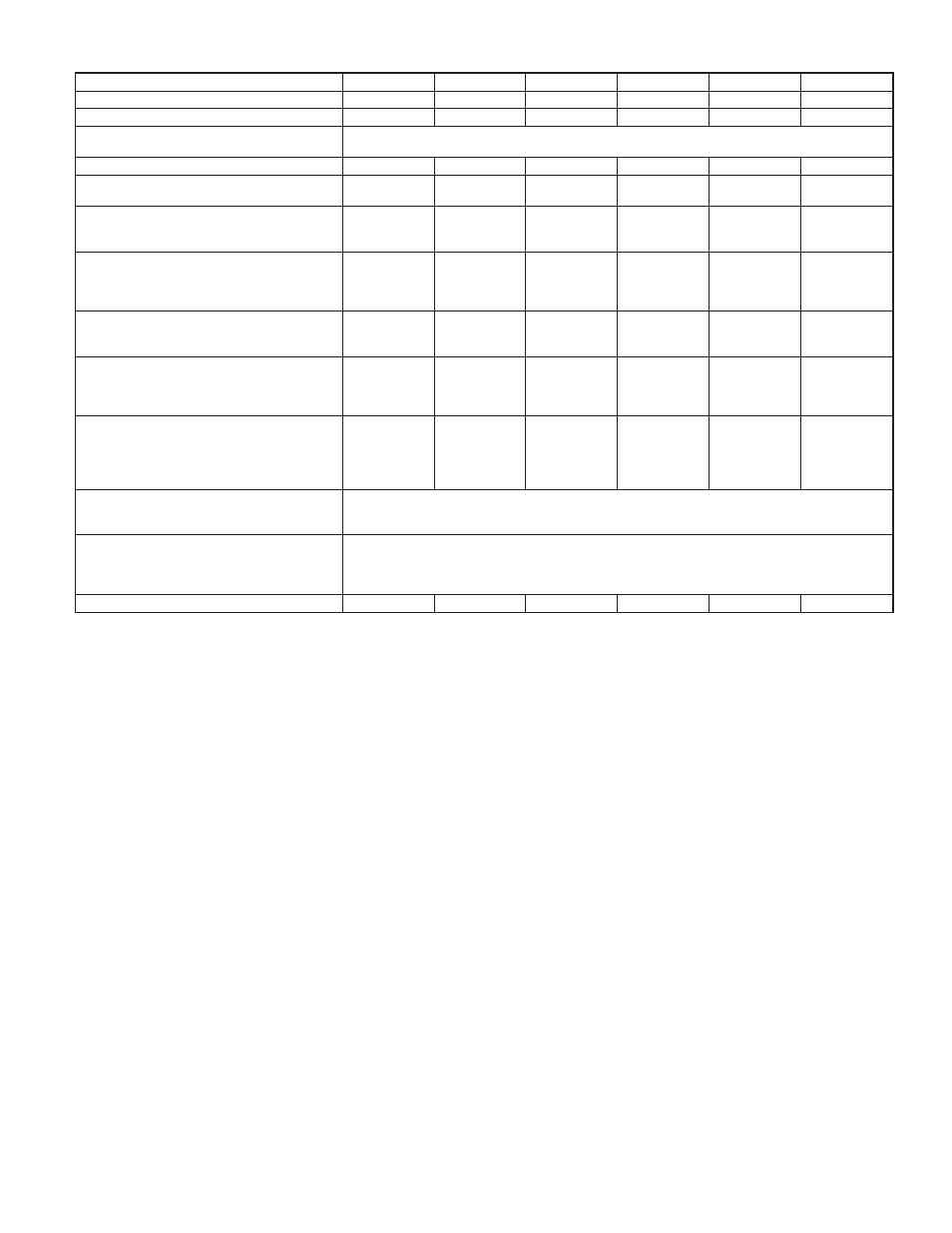

TABLE 2—PHYSICAL DATA — UNIT 583B — 030040-042090

UNIT SIZE 583B

030040

030060

036060

036090

042060

042090

NOMINAL CAPACITY (ton)

2 1/2

2 1/2

3

3

3 1/2

3 1/2

OPERATING WEIGHT (lb)

313

313

321

321

382

382

COMPRESSORS

Quantity

Scroll

1

REFRIGERANT (R-410A) Qty (lb)

5.5

5.5

6.9

6.9

9.0

9.0

REFRIGERANT METERING DEVICE

Orifice ID (in.)Check-Flo-Rater® Piston

.057

.057

.065

.065

.070

.070

CONDENSER COIL

Rows...Fins/in.

Face Area (sq ft)

1/17

12.7

1/17

12.7

2/17

9.1

2/17

9.1

2/17

12.3

2/17

12.3

CONDENSER FAN

Nominal CFM

Diameter (in.)

Motor Hp (RPM)

2350

22

1/8 (825)

2350

22

1/8 (825)

2350

22

1/8 (825)

2350

22

1/8 (825)

2350

22

1/8 (825)

2350

22

1/8 (825)

EVAPORATOR COIL

Rows...Fins/in.

Face Area (sq ft)

3/15

3.7

3/15

3.7

3/15

3.7

3/15

3.7

3/15

4.7

3/15

4.7

EVAPORATOR BLOWER

Nominal Airflow (CFM)

Size (in.)

Motor Hp

800

10 x 10

1/4

1000

10 x 10

1/4

1200

10 x 10

1/2

1200

10 x 10

1/2

1400

11 x 10

3/4

1400

11 x 10

3/4

FURNACE SECTION*

Burner Orifice No.

(Qty...Drill Size) Natural

Burner Orifice No.

(Qty...Drill Size) Propane

2...44

2...50

2...38

2...46

2...38

2...46

3...38

3...46

2...38

2...46

3...38

3...46

HIGH-PRESSURE SWITCH (psig)

Cutout

Reset (Auto.)

610

± 15

420

± 25

LOSS-OF-CHARGE/LOW-PRESSURE

SWITCH (Liquid Line) (psig)

Cutout

Reset (Auto.)

20

± 5

45

± 10

RETURN-AIR FILTERS (in.)Throwaway

20 x 24x1

20 x 24x1

20 x 24x1

20 x 24x1

24 x 30x1

24 x 30x1

—9—