Fast & Fluid Giotto Column User Manual

Page 19

Fast & Fluid Management

A Unit of IDEX Corporation

________________________________________________________________________________

________________________________________________________________________________

18

1154915C-it,en,fr.doc - 15/10/2003

Note :

The reduction unit which has been applied on the rotating table and all others

components DO NOT need ANY lubrication because they are life - lubricated.

In order to have a costantly good performance of Giotto manual dispenser the following procedure

are daily recomanded.

-

Check the quantity of colourant : mantain at least 2 litres of colourant in the canister.

-

Before each dosing stir the colourant.

-

Also if you don't use the dispenser daily, open and close the valve, pull and push the pump

handle without opening the valve.

Repeat the action two or three times.

-

Clean the nozzle using a moistened cloth to take off the dried colourants.

Depending on use it is important to carry out periodic check (about 6 months)

-

Check gauges for graduated scales and replace if required.

-

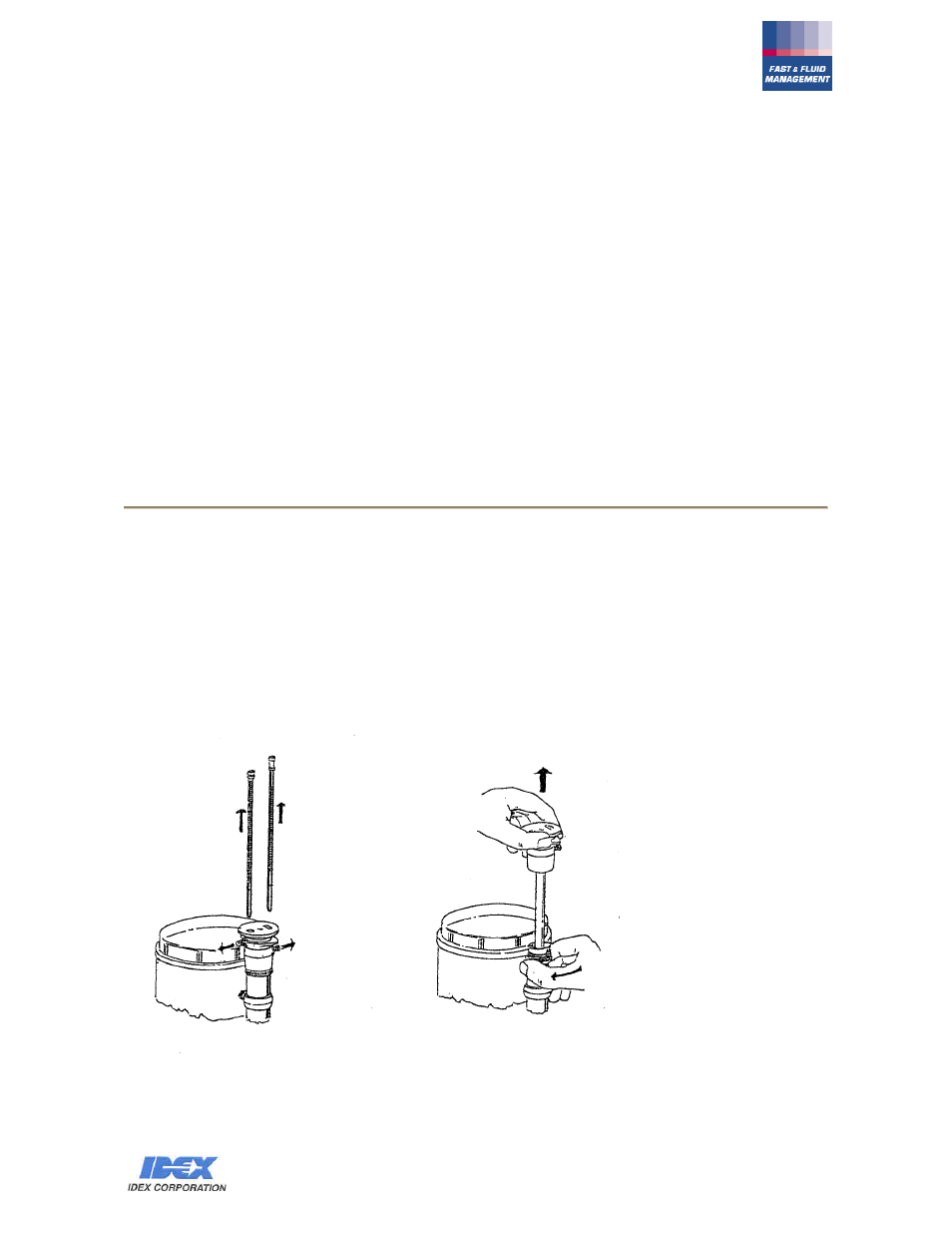

Lift both pumps to the maximum extention and check if the shafts have signs of

colourant which indicate the need to replace the piston seal as indicated in

(DIAGRAM 10)

-

Inspect the valve and canister for leaks , if required replace the "O" Ring

disassembling the valve as indicated in DIAGRAM 9.

-

When you discarge a canister for cleaning or maintenance you have to repeat the

" Dispenser Preparation" process.

11.- CONTAINER CLEANING

d)

Extract all paint from the containers

e) Put inside about 1 liter water and let operate for about 15 minutes together with the simultaneous

action of the stirrer

f)

Empty completely the containers operating the pumps : in this way it is possible to clean the

containers, the pistons and the valve. If this operation should be insufficient, extract completely

the measuring rods, screw out the ring nut body, extract the piston unit and remove the internal

piston.

DIAGRAM 10

Clean all elements carefully and remount them (following the same instructions for the dismounting

and carrying them out in the opposite sequence).