Fast & Fluid Giotto Column User Manual

Page 18

Fast & Fluid Management

A Unit of IDEX Corporation

________________________________________________________________________________

________________________________________________________________________________

17

1154915C-it,en,fr.doc - 15/10/2003

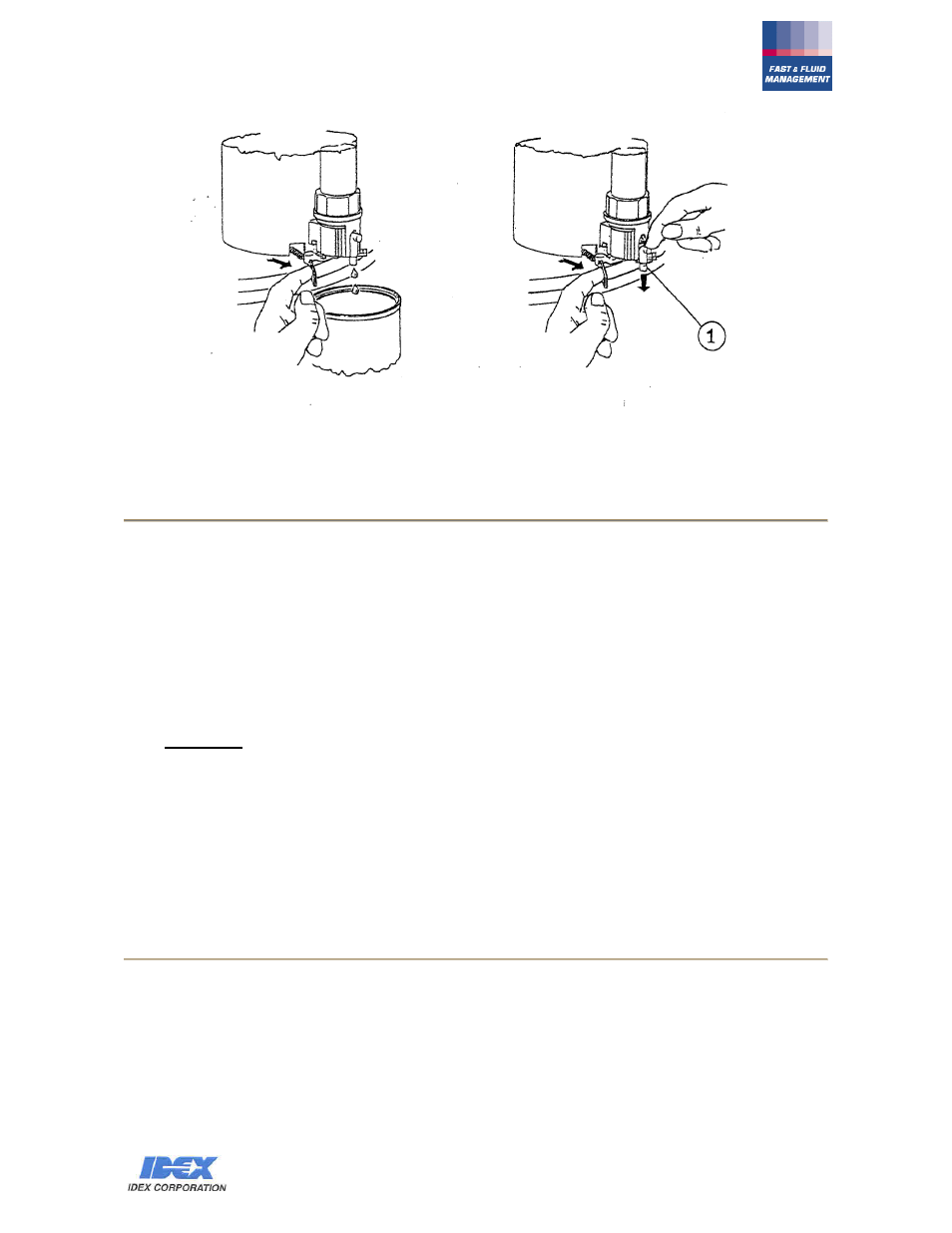

DIAGRAM 9

Position the can support shelf so that the container to be filled is at no more than 10 cm. from

the pump nozzle.

9.- DOSING INSTRUCTIONS

1)

Be certain to have identified the colour from your formula data base.

2)

Identify the can size for the correct quantity and place the open can of base paint on the

shelf directly under the nozzle of the valve.

3)

According to the quantity required set both gauges at the correct value locking the knob.

The correct gauge position is found when the figure selected is fully exposed above the upper

handle and the knob is firmly locked into the hole in the gauge.

4)

Lift slowly the handles until both are against the appropriate gauge knobs.

WARNING

If the quantity of colourant in the canister is too low, air can get inside the pump and the dosing is

not correct. There should be at least 2 litres of colourant in the canister.

5)

Arrived at the top position of the handle , turn the valve lever forward to its full stroke

6)

With the valve lever in open position press the handle of the pump , ensure that both handles are

fully depressed.

All the colourant requested has been discharged.

7)

Set the valve lever in its normal position.

8)

Repeat the process for each colourant specified by the formula.

9)

If you have to prepare several containers using the same formula and quantity, you can leave

the gauge preset and operate as previously described. (DIAGRAM 7)

10.- MAINTENANCE

The maintenance has to be carried out about every three months and is compriced of following

phases:

a)

Lubricate the little supporting wheels of the turnig table

b)

Lubricate the fulcrum and the chain for the table movement.

c)

Lubricate the rotation support of the turning table.