Preparation of bull bar – ARB 3915040 User Manual

Page 15

Last Rev Date: 28 OCTOBER 2008

Page 15 of 22

Fitting instructions# 3781218

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

PREPARATION OF BULL BAR

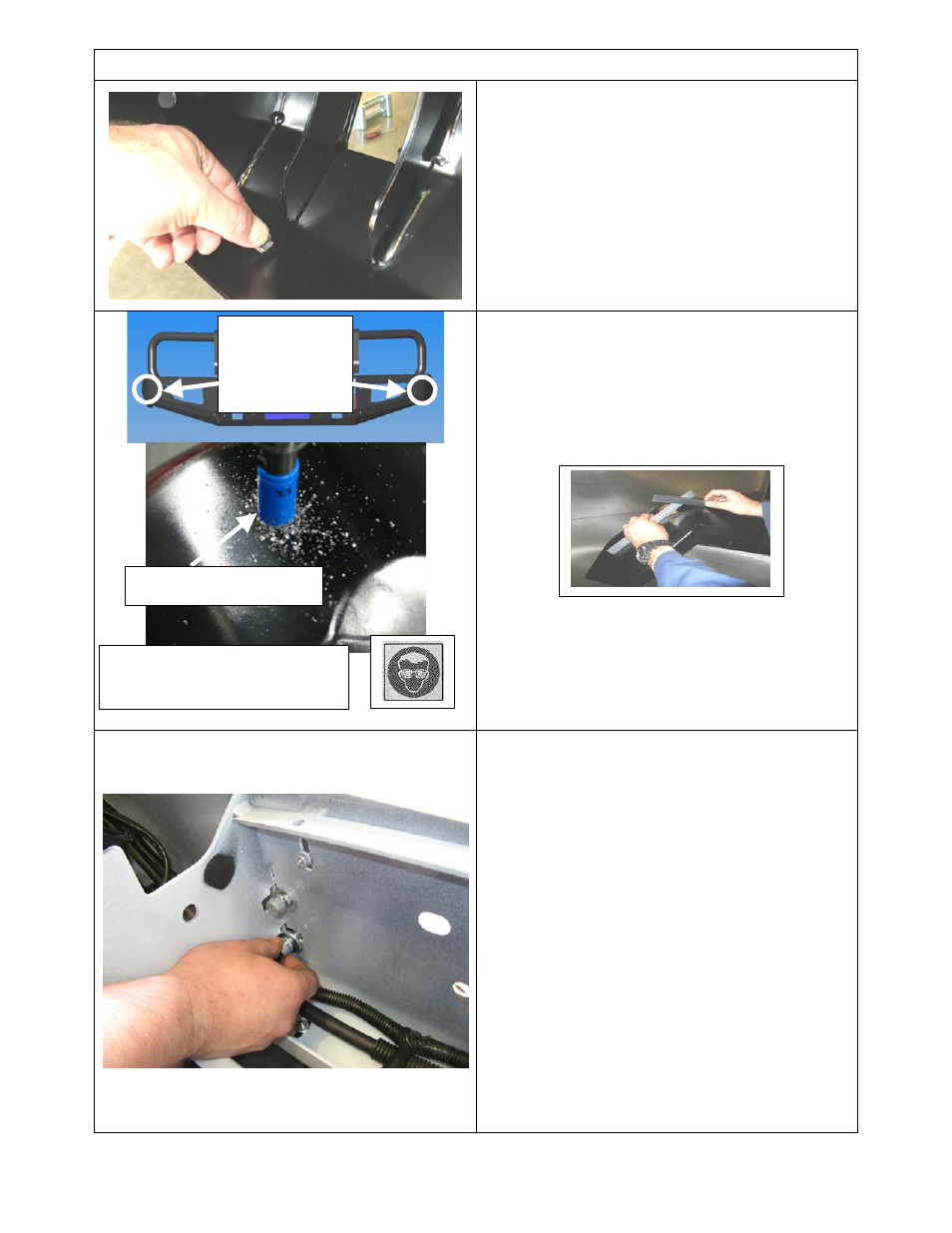

59. Fit 4 x M6 cage nuts to bottom inside

face of lower pan in square holes as

shown.

Hint: A small flat blade screwdriver may help to

press nut cage flanges into hole.

60. If parking sensors are to be fitted, mark

out the hole positions, located in the

middle of the large corner radius of the

wings and 90mm down from the top face.

(Similar position to original bumper)

Hint: Use two rules across flat faces to find

mid point of radius

61. Once Dia 22 (7/8”) hole is drilled and

fully deburred, check that the hole size is

actually Dia 22.0 – 22.8mm, better if on

larger side. Trial fit sleeve and sensor.

62. Once checked use some fast drying

primer paint to seal bare edges.

IF FITTING FRAME AND BUFFERS

63. If fitting centre frame, loose fit the pair of

buffers with holes P#3163017R&L by

sliding up onto frame, noting that the

buffers are handed.

64. Mount frame and secure with 2 sets of

M10 x 40 cap screws and washers per

side as shown, noting that the frame leans

rearwards once on vehicle

65. Slide buffers down over frame until they

sit correctly onto bull bar and tube profile.

66. Fasten buffers with 6 x M6 flange nuts

per buffer once buffers are carefully

pushed home against the profile of the

bull bar and centralised over tube, be

careful not to over tighten the flange nuts

as damage to buffer can result.

Warning: Cutting operations

can result in flying debris, safety

glasses should be worn.

Sensors fit on

these outer

corners, 90mm

down from top

face

Hole saw Dia 22.0 (7/8”)