Bull bar fitment to vehicle – ARB 3421520 User Manual

Page 17

Last Rev Date: 14/10/2010

Page 17 of 22

Fitting instructions# 3787836

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

BULL BAR FITMENT TO VEHICLE

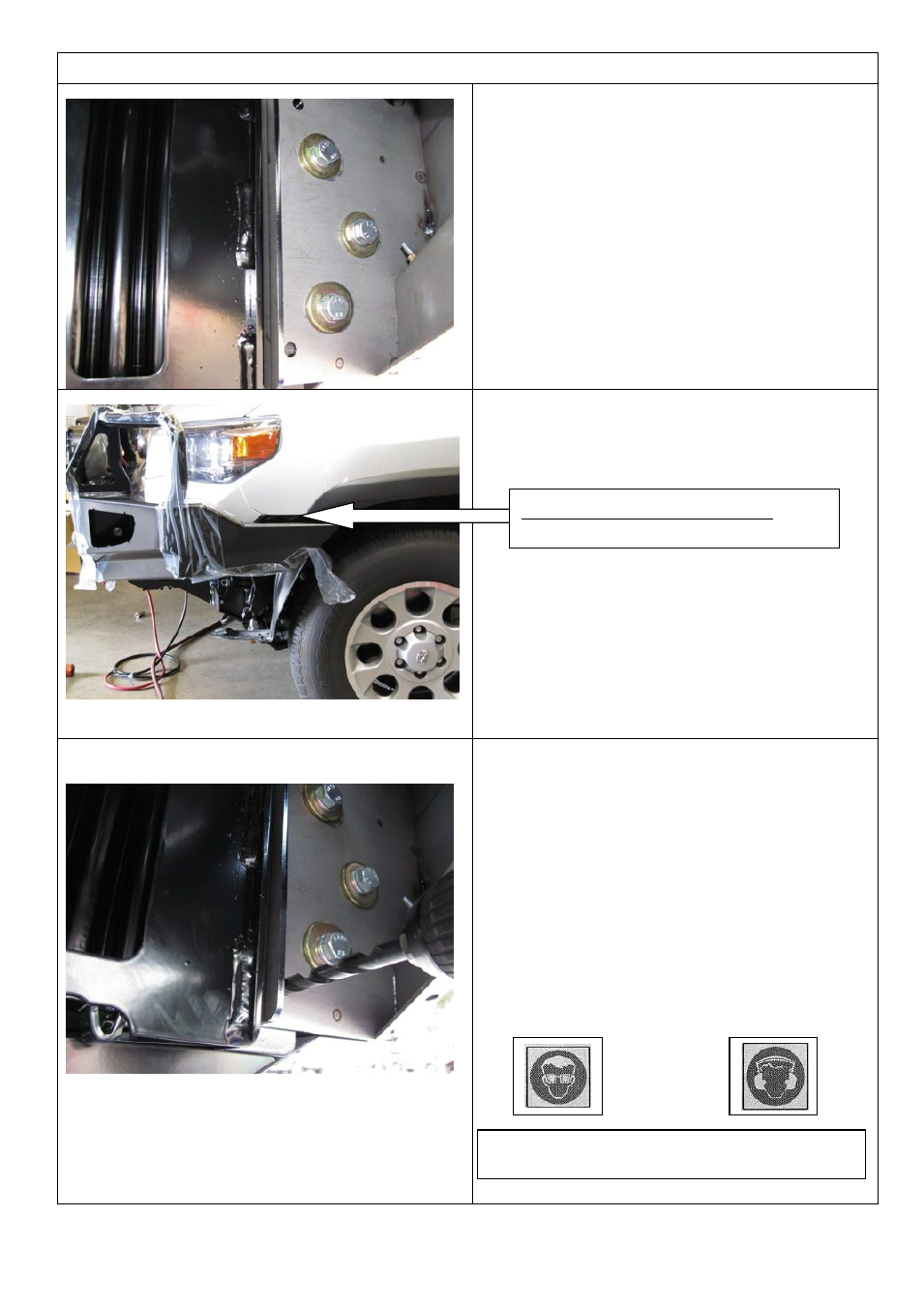

67. With assistance guide the bull bar into

position on the vehicle. The uprights on the

bull bar sit outside the impact absorber

blades.

68. Bolt the bull bar into position using the M12

bolts, spring washer, large body washer and

flange nuts 3 places per side of bull bar as

shown. Tighten the bolts firmly ± but allow

enough movement for the bull bar to be

adjusted

69. If winch fitted route cables up into the engine

bay and secure.

70. Ensure the bull bar is sitting on the vehicle

level and the gap between the bumper bar

cut and the bull bar wing is even.

71. If the bull bar is not centred on the vehicle,

back off the mount bracket bolts to chassis,

tap the mount brackets sideways with a soft

hammer until the bar is central. Retention

bolts to specified torque

72. Once happy with the position of the bull bar

and the clearance gap is 16-20mm, tighten

all the mount bolts to specified torque

73. Using an electric drill and a Dia10.0 mm drill

bit, drill two pinning bolt holes through the

bull bar upright each side using the holes in

the mount bracket flanges as a guide. One

hole is located in the lower lug of the mount

face and one up above the welded nuts. Use

access through the light surround opening for

the top hole.

74. Fit the pinning bolts to the bull bar in the

drilled positions using 4 x M10 SEMS bolt

and washer sets and M10 flange nuts and do

up to specified torque.

16-20 mm (5/8 -´*$3

REQUIRED

Warning: Drilling operations can result in flying

metal debris, safety glasses should be worn.