Aster, Ntake, Alve – Hale Master Intake Valve User Manual

Page 26

24

M

ASTER

I

NTAKE

V

ALVE

20. Reinstall the gearbox onto the gearbox

adapter by lining up square end of shaft

with square bore in gearbox.

21. Apply Loctite #242 or equal to four

3

/

8

-16

x 2-½ inch long cap screws. Tighten cap

screws.

22. Apply a light coat of Sunoco Ultra

Prestige 2EP grease or equal to the valve

bore and the disc edges.

23. Back out the gearbox mechanical stops.

On manual valves (MIV-M) they are

located under the rubber plugs on side

of gearbox.

24. Connect the wiring harness and turn

power on to illuminate panel placard

lights.

25. Manually close valve. Using a reference

point, such as the valve body mounting

surface, measure the disc position.

Refer to figure 11, the valve disc edge

should be an equal distance from this

reference point. The valve disc is now

centered in the valve body in the closed

position.

NOTE: The gearbox adapter has

oversized mounting holes that allow

some adjustment to be made to set the

timing of the closed light/motor

operation versus disc position.

26. Slightly loosen the two

7

/

16

-14 x 1 inch

long counterbore screws that hold the

gearbox adapter to the valve body.

27. Manually turn back gearbox handwheel

a small amount until gearbox and

gearbox adapter are free to move. Find

the mid position of this free play and

tighten the two mounting screws.

28. Operate the valve to the open position,

then:

a. Manual valves (MIV-M)

a) Manually operate back to the

closed position. Stop when the red lamp

is lit.

b. Electric valves (MIV-E)

a) Use gearmotor to operate valve

to the closed position and allow the

switches to stop rotation.

b) The lamps should sequence from

amber to red then the motor should

stop.

29. Measure the disc position. Refer to

figure 11, the valve disc edge should be

an equal distance within ±

1

/

16

inch from

this reference point.

EXAMPLE: If A measures

5

/

8

inch, then B

must be within

9

/

16

to

11

/

16

inch.

30. If measurement is OK proceed to step

31. Otherwise loosen gearbox adapter

mounting screws and manually turn the

handwheel

1

/

8

turn in one direction and

tighten mounting screws. Repeat steps

28 and 29. If the measurement is worse

than before loosen gearbox adapter

mounting screws and manually turn the

handwheel ¼ turn in the opposite

direction and tighten mounting screws.

Repeat steps 28 and 29.

31. When the disc, in the closed position, is

within the ±

1

/

16

dimension the closed

position mechanical stop can be set.

a. Manual valves (MIV-M)

a) Tighten the screw until it stops. Do

not over tighten. Operate valve in both

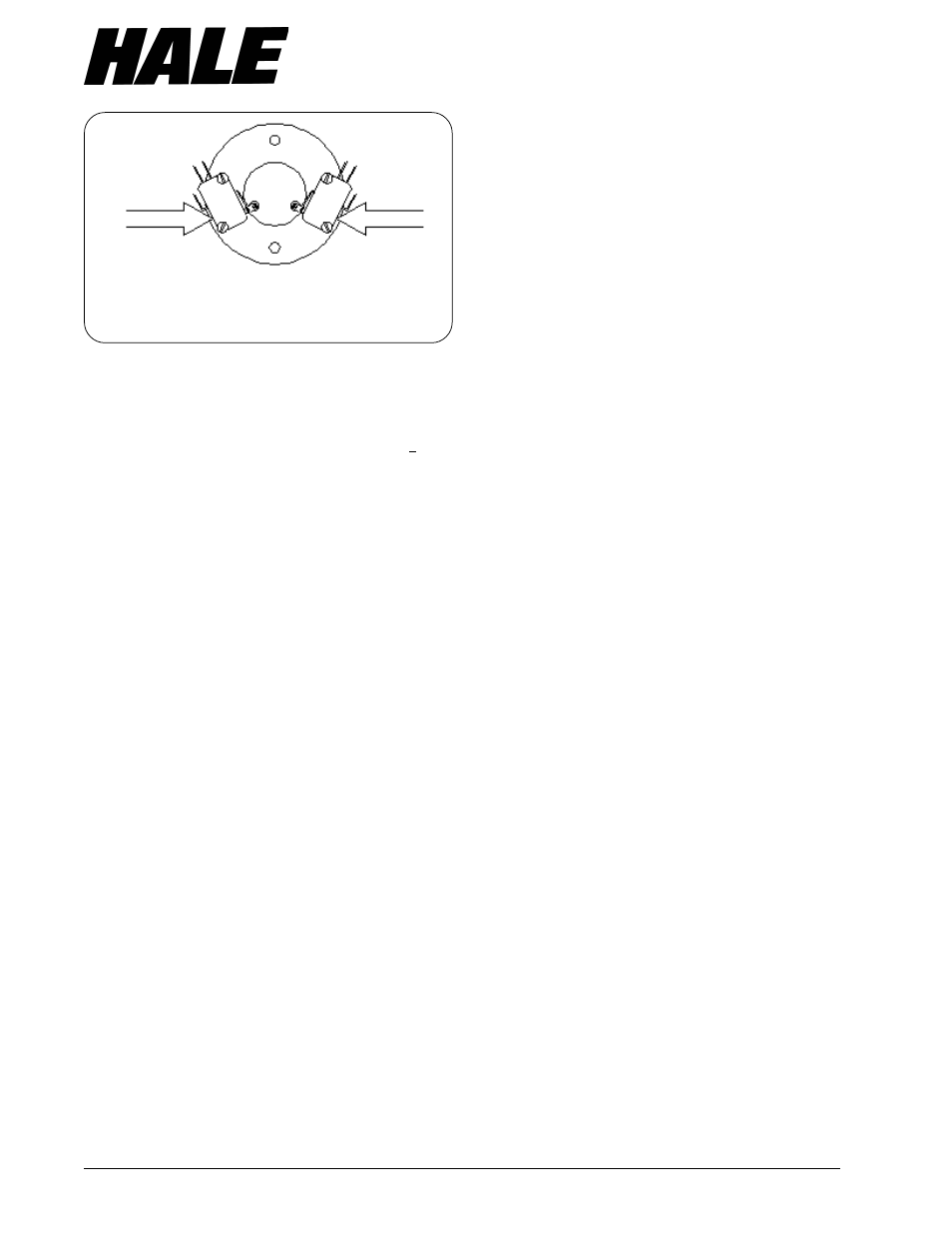

Figure10. Micro Switch Tightening

PINCH MICRO SWITCHES WHERE INDICATED BY

ARROWS WHILE TIGHTENING SCREWS