Perform startup checks and adjustments – Burnham ES2 User Manual

Page 16

16

10-b

10. PERFORM STARTUP CHECkS AND ADjUSTMENTS

FAILURE TO PERFORM THESE

CHECKS of the boiler's combustion and

safety systems may result in serious property

damage, injury, or death.

IF YOU SMELL GAS, STOP and repair

the leak. Lighting the boiler when gas is

leaking may cause explosion or fire.

Follow the checklist below:

1.

Verify that the venting, water piping, gas

piping, and electrical systems are properly

installed and checked.

2.

Apply power to the boiler.

3.

Adjust zone thermostat to maximum setting.

4.

Allow gas line to purge of air.

q

Boiler lights cleanly within 60 seconds.

5.

Adjust gas input rate. See Appendix F

– Adjusting Gas Input Rate

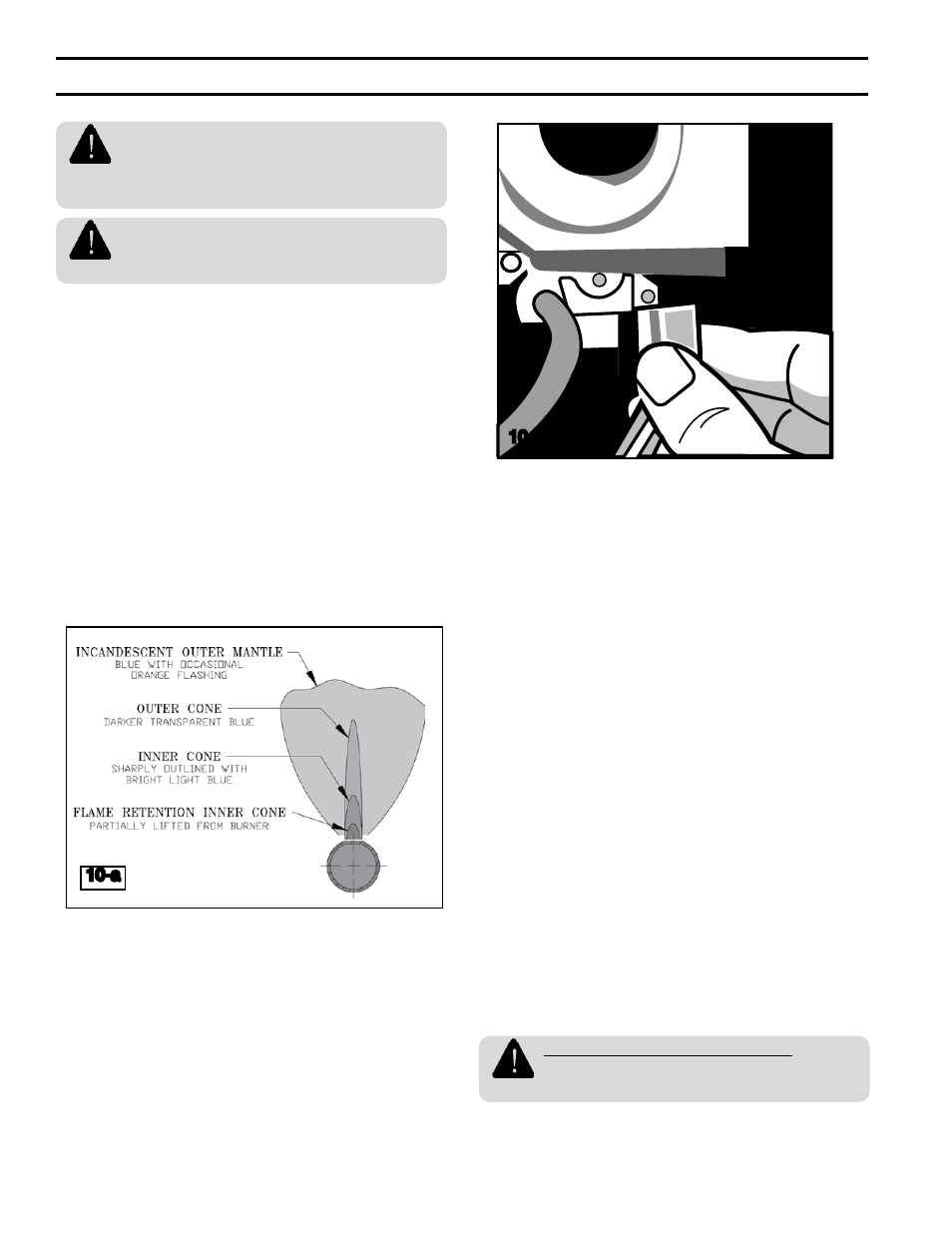

10-a

q

Pilot and main burner flames appear

clean and blue.

6.

Disconnect pilot lead wires from gas valve

(Figure 10-b).

q

Boiler shuts off.

7.

Reconnect pilot lead wires to gas valve.

q

Boiler restarts.

8.

Adjust zone thermostat to minimum setting.

q

Boiler shuts off.

9.

Adjust zone thermostat to maximum setting.

10.

Observe temperature gage as boiler heats.

11.

Adjust the high limit setting to its minimum

level (see "Programming High Limit" in

Section 8).

q

Boiler shuts off when temperature gage

reads within 15°F of high limit setting.

12.

Return high limit to the desired setting (see

"Programming High Limit" in Section 8).

13.

Check draft. See Appendix G

– Checking Draft and Combustion.

q

No spillage observed.

14.

Check combustion in the vent stack and

record results in the spaces provided below.

_____ CO

2

(less than 7%)

_____ O

2

(more than 9%)

_____ CO (less than 100 ppm, air free)

ANY FAILED STARTUP CHECK

Must be corrected before placing the

boiler in service.