Cutter bar adjustments – Alamo JD-5225 User Manual

Page 56

© 2005 Alamo Group Inc.

Section 7 - 2

Switch Blade (JD-5105-5205-5225-5325-5425-5525, Asy. Man) 05/05

CUTTER BAR ADJUSTMENTS

Figure 3

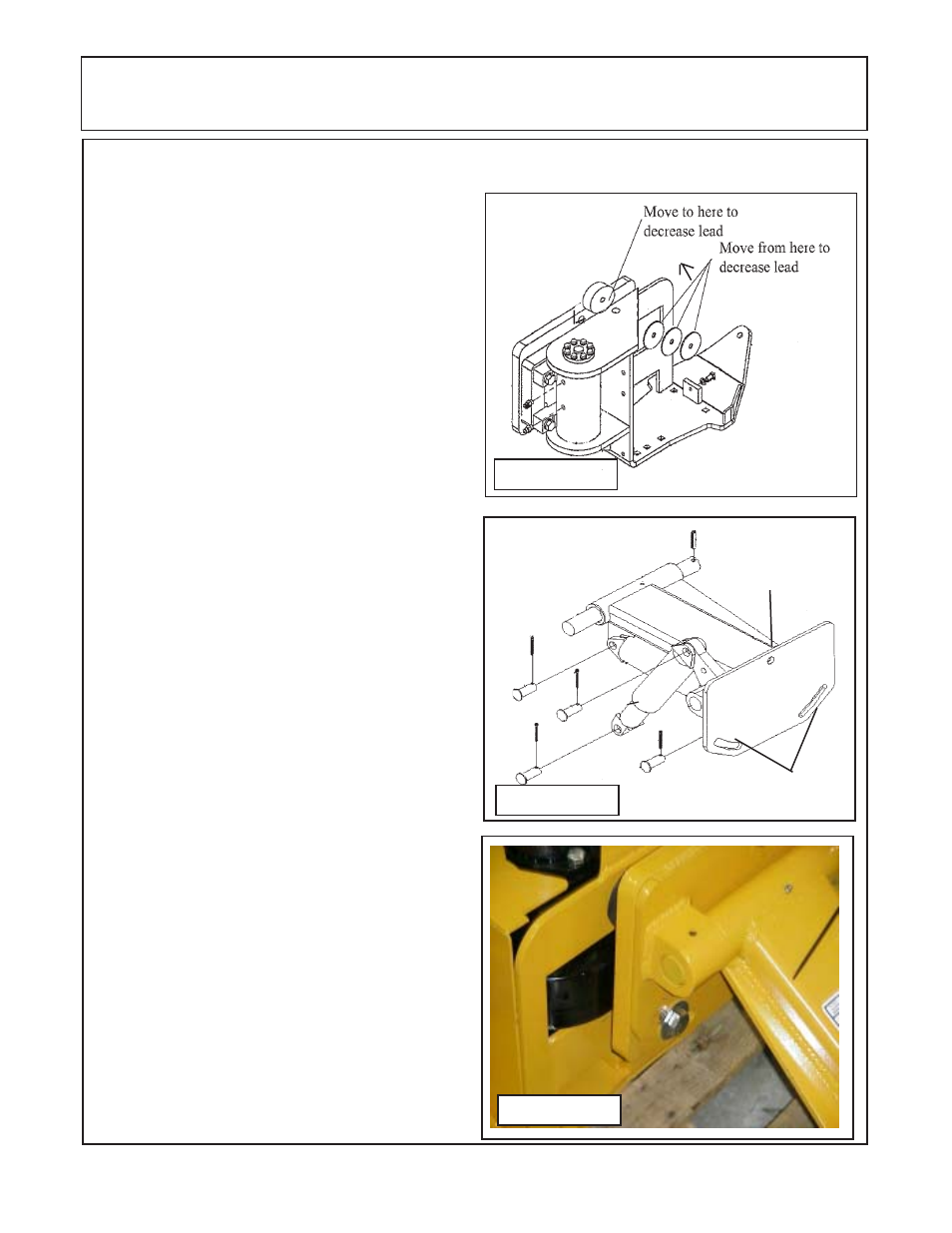

Lead Adjustment:

The lead angle is how far the outer end of

the cutter bar runs forward of the inner end.

The lead angle of the cutter bar is preset at

the factory at 3/6" per foot. The lead may be

changed if desired. To reduce the lead, move the

washers from the outside of the cutterbar support

plate in between the rubber strike pad and plate

(See Figure 3).

Pitch Adjustment:

The Pitch angle is the level of the cutter bar

front to rear or what angle the blade is to level front

to rear. Different cutting conditions allow you to

change the pitch of the knife by + 15° to - 15° or

level.

The pitch is set by loosening the three

mounting bolts that connects the skid shoe /

Break-A--Way assembly to the carriage arm as-

sembly (See Figure 4 & 4A). The two lower bolts

holes are slotted, this will allow the cutter bat to be

tipped up +15° or down -15° in front. Set Pitch at

what works best for your application.

Cutter Bar Alignment:

All cutting is done by the knife passing over

ledger plate in the guard. It is vital that these

sections are parallel with the plates and in contact

with them, (See Figure 5 & 6).

The knife should move smoothly in the

cutterbar guides and every knife section should

rest on the ledger plate to make a shear cut. This

means the guards, ledger plate, wear plates, clip

and knife head caps must be in good condition and

correctly set. If these parts become loose or worn,

the knife will flop around in the cutter bar, chewing

and tearing instead of cutting.

Guard Adjustment:

1.

To align the guards, the only method pro-

vided to accomplish this very important adjust-

ment is to bend the guards into alignment with a

hammer. No easier method has been found to

adjust heavy duty guards which will stand up in

rocky conditions.

Figure 4

Slotted Holes

Non-Slotted

Hole

Continued Next Page

Figure 4A