Carriage arm assembly replacement – Alamo JD-5225 User Manual

Page 65

© 2005 Alamo Group Inc.

Section 7 - 11

Switch Blade (JD-5105-5205-5225-5325-5425-5525, Asy. Man) 05/05

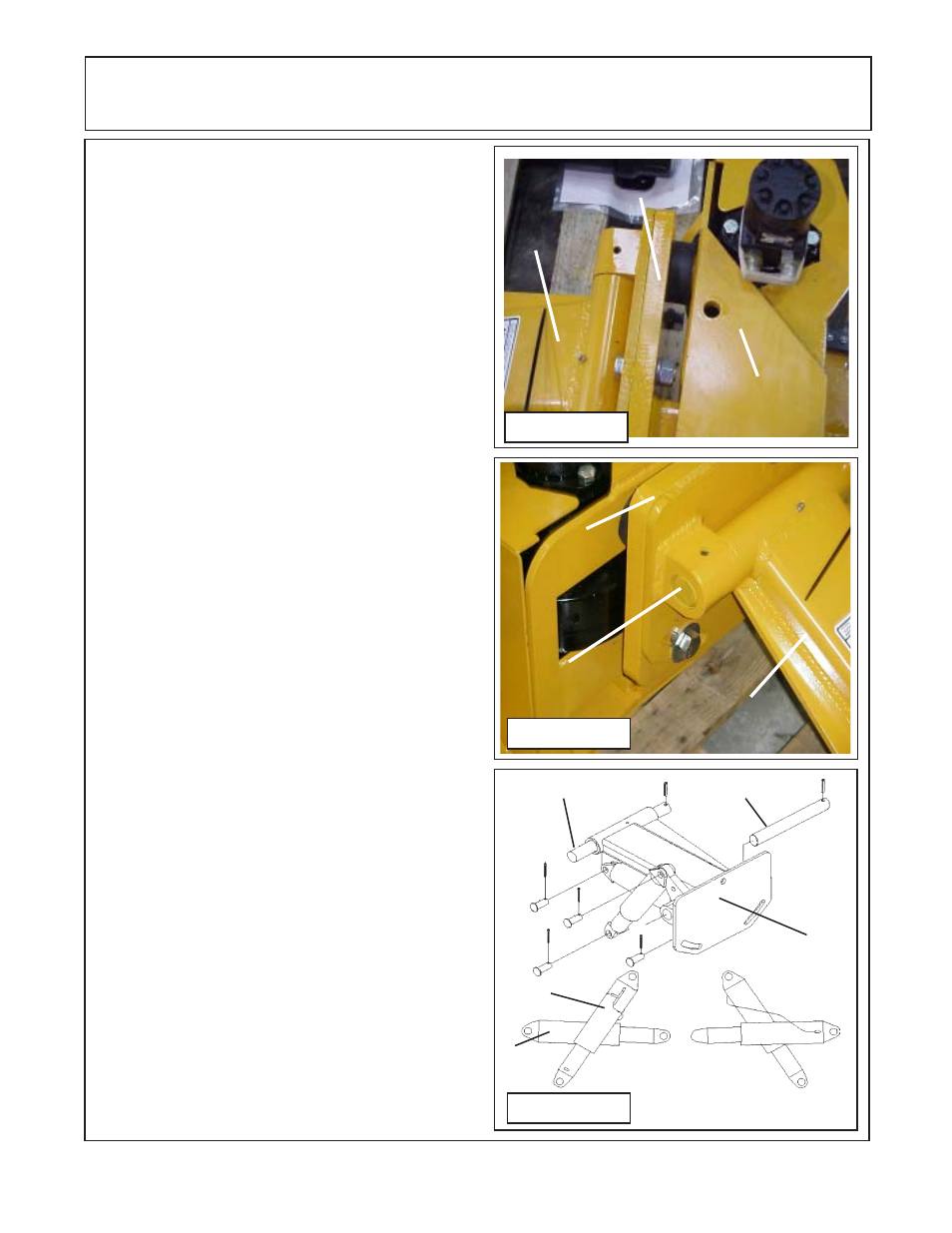

CARRIAGE ARM ASSEMBLY REPLACEMENT

Carriage Arm Assembly Replace-

ment:

The carriage arm replacement will require

the Back Pivot Plate to be unbolted with the skid

shoe / break-a-way assembly to be removed with

Back Pivot but not disassembled. The skid shoe /

break-a-way assembly can be removed by unbolt-

ing the back pivot plate from the carriage arm (See

Figure 17 thru 25). The hydraulic hoses to the

motor will not have to be disconnected but the hose

brackets may have to be disconnected to allow the

assembly to be moved outward far enough to clear

carriage arm assembly. If the complete cutterbar /

break-a-way assembly needs to be moved it is

sometimes easier and cleaner to unbolt the motor

and the complete assembly can be removed an the

motor can be moved out of the way with the hoses

attached to it. DO NOT pull assembly with the

hoses attached and damage them.

To remove the carriage arm the lift and tilt

cylinder will need to be disconnected, the hoses will

not require disconnecting, the cylinders can be set

aside with the hoses connected. Remove the roll

pins from the carriage pin. The carriage arm is

pinned to the back pivot plate and the tractor main-

frame. The mounting frame to attach to the tractor

will vary from tractor model, but the way the car-

riage arm is pinned to will not. Drive the carriage

pins out and carriage arm will lift out (See Figure 24,

25 & 26).

To reassemble the carriage arm reverse

the disassembly instruction, insert carriage arm,

insert carriage arm pins, install roll pin in to carriage

arm pin. Install the lift and tilt cylinders, make certain

hoses connecting to the cylinders is not twisted or

routed wrong as they could be damaged. Attach the

back pivot plate with the carriage pin. Bolt the

cutterbar / skid shoe assembly to the back pivot

plate, note the two lower holes in back pivot plate

are slotted on a curve. Flatwashers will have to be

used on these two lower bolts (See Figure 25). The

pitch of the cutter bar will have to be readjusted, see

pitch adjustment instructions in earlier pages (See

Figure 4 & 26)

Carriage Arm

Assembly

Back Pivot

Plate

Inner Shoe

Wledment

Figure 24

Figure 25

Figure 26

Carriage Arm

Assembly

Carriage Arm

Pin

Back Pivot

Plate

Carriage Pin

Carriage Pin

Carriage Arm

Rear View

Front View

Curb Lift Cyl.

Bar Tilt

Cyl